Annular beam device and method for adjusting local flow velocity of pipeline

A technology to adjust the pipeline and flow rate, which is applied in the direction of valve device, valve details, valve shell structure, etc., can solve the problem that the steam flow rate is difficult to adjust in time, and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

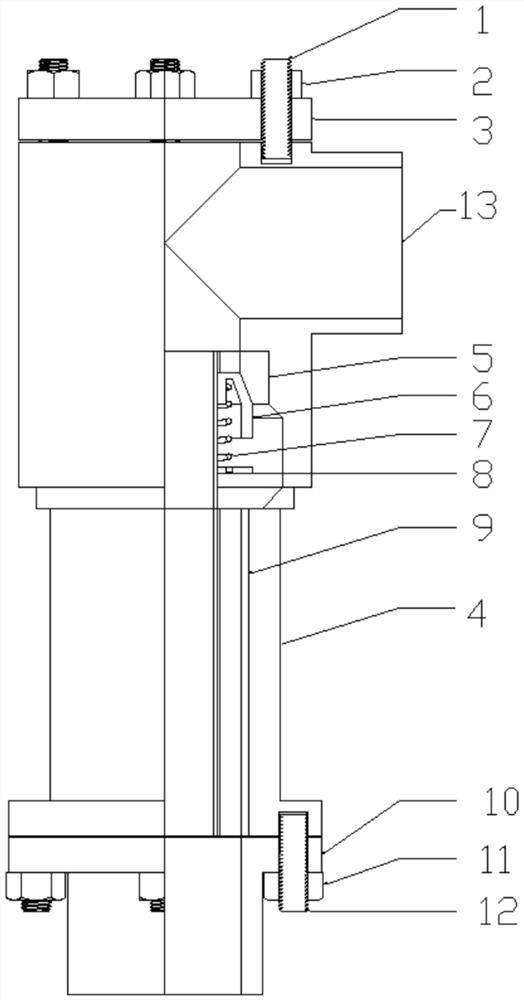

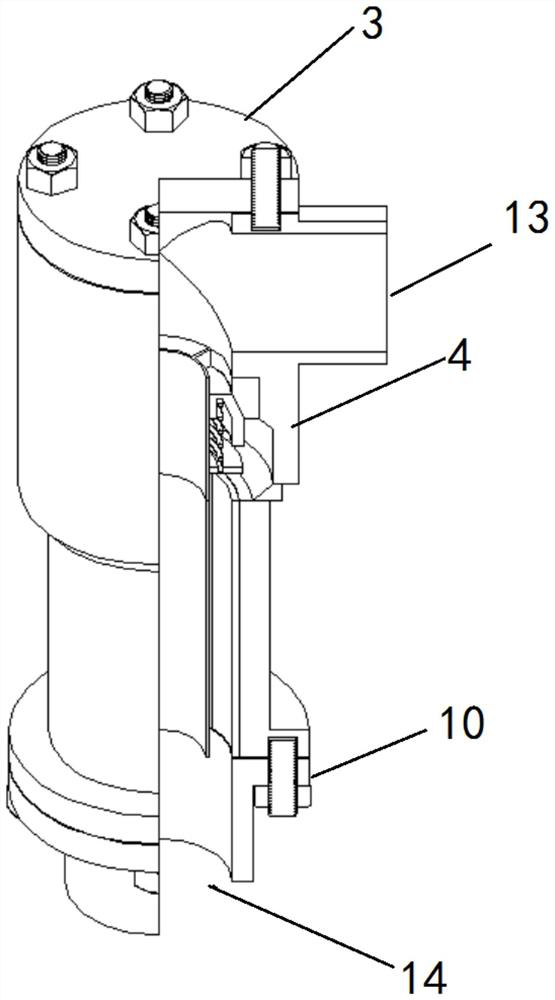

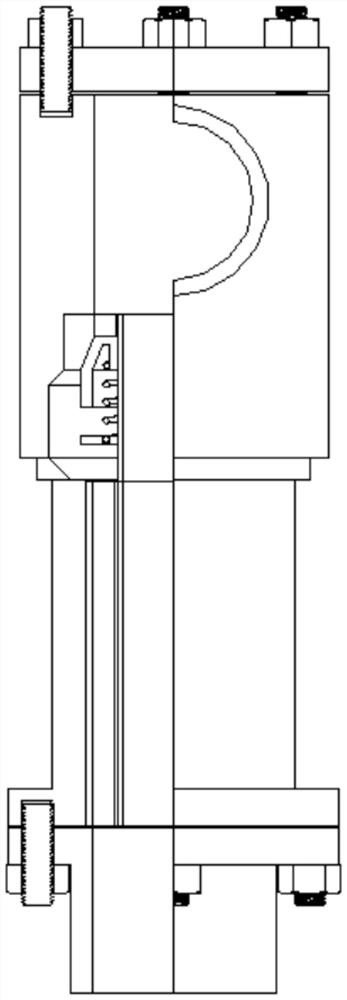

[0044] see figure 1 , figure 2 , image 3 and Figure 4 , the side wall of the valve body 4 is provided with a working fluid inlet 13, the axis of the working fluid inlet 13 is perpendicular to the axis of the valve body 4, and the inside of the valve body 4 is sequentially provided with a splitter sleeve 5 and a double flow channel from top to bottom. The upper end surface of the sleeve 9 and the splitter sleeve 5 is below the inlet 13 of the working fluid.

[0045] see Figure 5 and Figure 6 , the splitter sleeve 5 and the valve body 4 are coaxial, the splitter sleeve 5 includes a coaxial inner ring 501 and an outer ring 502, the inner ring 501 is arranged in the outer ring 502, and the two do not touch; the inner ring 501 and the outer ring 502 are connected by the first connecting plate 504, the first connecting plate 504 is equally divided along the circumference of the outer ring 502, the first connecting plate 504 is arranged along the length direction of the val...

Embodiment 2

[0050] see Figure 7 and Figure 8 , the entire valve of this embodiment is a straight-through type, the working fluid inlet 13 is set on the valve cover 3 at the inlet end, and the working fluid inlet 13 and the valve body 4 are coaxial.

[0051] The working method of above-mentioned two embodiments is:

[0052] When the flow rate of the working fluid is lower than the set value, the beam ring 6 is pressed upward by the spring 7, and the first slope 503 and the second slope 601 are sealed against each other under the support force of the spring 7 and the magnetic force; The inlet 13 enters the valve body 4, the working medium passes through the inner ring 501, passes through the inner sleeve 901 of the double-channel sleeve 9, and flows out from the working medium outlet 14;

[0053] When the flow rate of the working fluid is greater than the set value, the thrust given by the working fluid to the beam ring 6 from above overcomes the magnetic force and the supporting force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com