Direct-current electric arc furnace

A DC electric arc furnace and electric arc furnace technology, applied in the field of metallurgical equipment, can solve the problems of small dumping angle, restricting the dumping and maintenance of electric arc furnaces, and large use limitations, so as to increase the turning angle, improve the service life, and have high applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

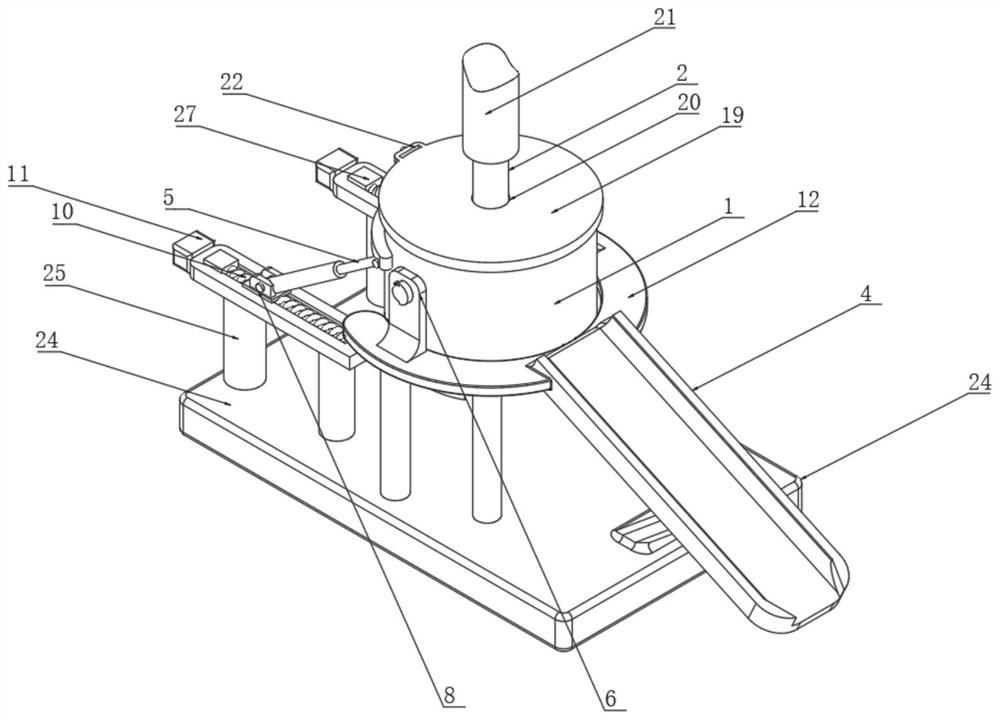

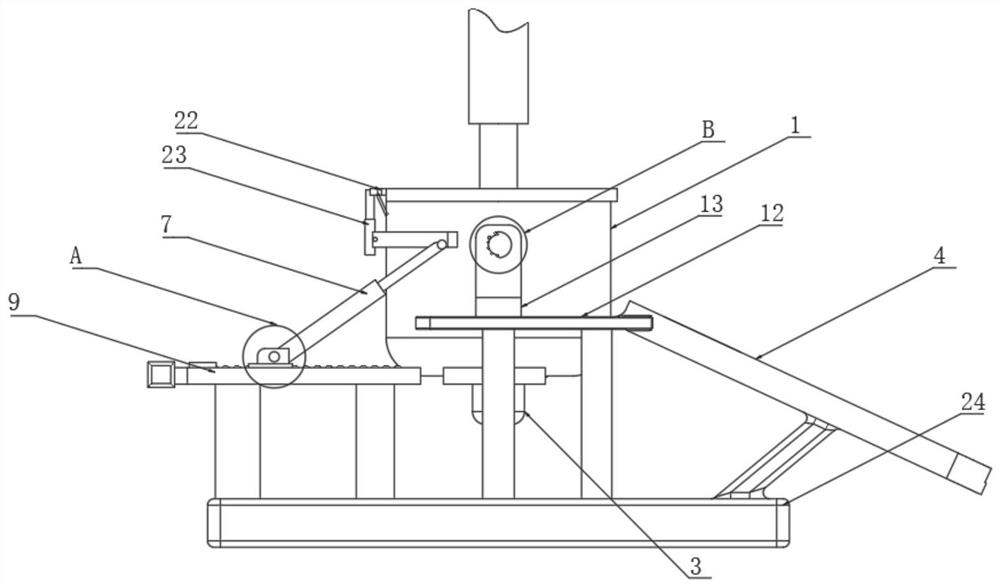

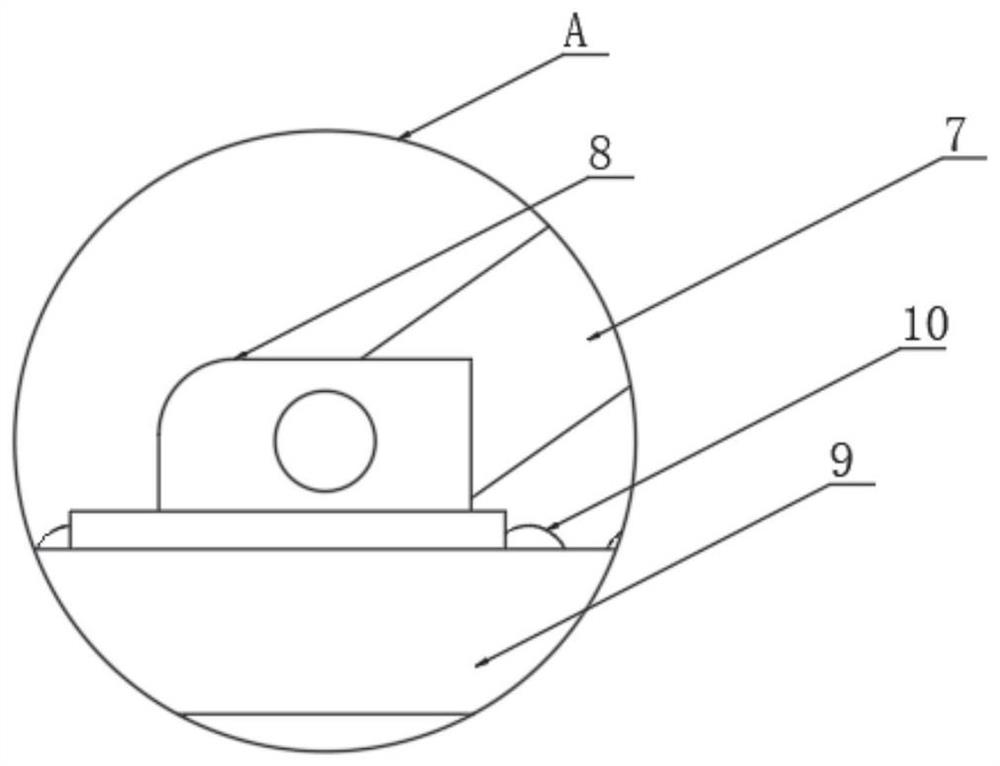

[0040] The specific embodiment, when the electric arc furnace body 1 is to be turned over, the first electric push rod 7 can be started, and the first electric push rod 7 arranged obliquely will exert a thrust on the electric arc furnace body 1, and the electric arc furnace body 1 will rotate around the rotating shaft. 14 is the center to turn clockwise to realize the dumping of the electric arc furnace body 1. When the electric arc furnace body 1 needs a larger turning angle, the synchronous motor 11 can be started, and the output shaft of the synchronous motor 11 drives the fixedly connected screw 10 to rotate, and the screw 10 rotates At the same time, the two sliders 8 will be pushed to slide along the direction of the chute 18, and the sliders 8 will gradually approach the electric arc furnace body 1, thereby increasing the turning angle of the electric arc furnace body 1 through the first electric push rod 7, breaking through the traditional electric push rod adjustment l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com