High-rank coal seam free gas content measuring device and measuring method

A technology for measuring devices and measuring methods, which is applied in the field of oil and gas exploration, can solve problems such as measurement data errors, achieve data accuracy, improve adsorption efficiency and adsorption quality, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

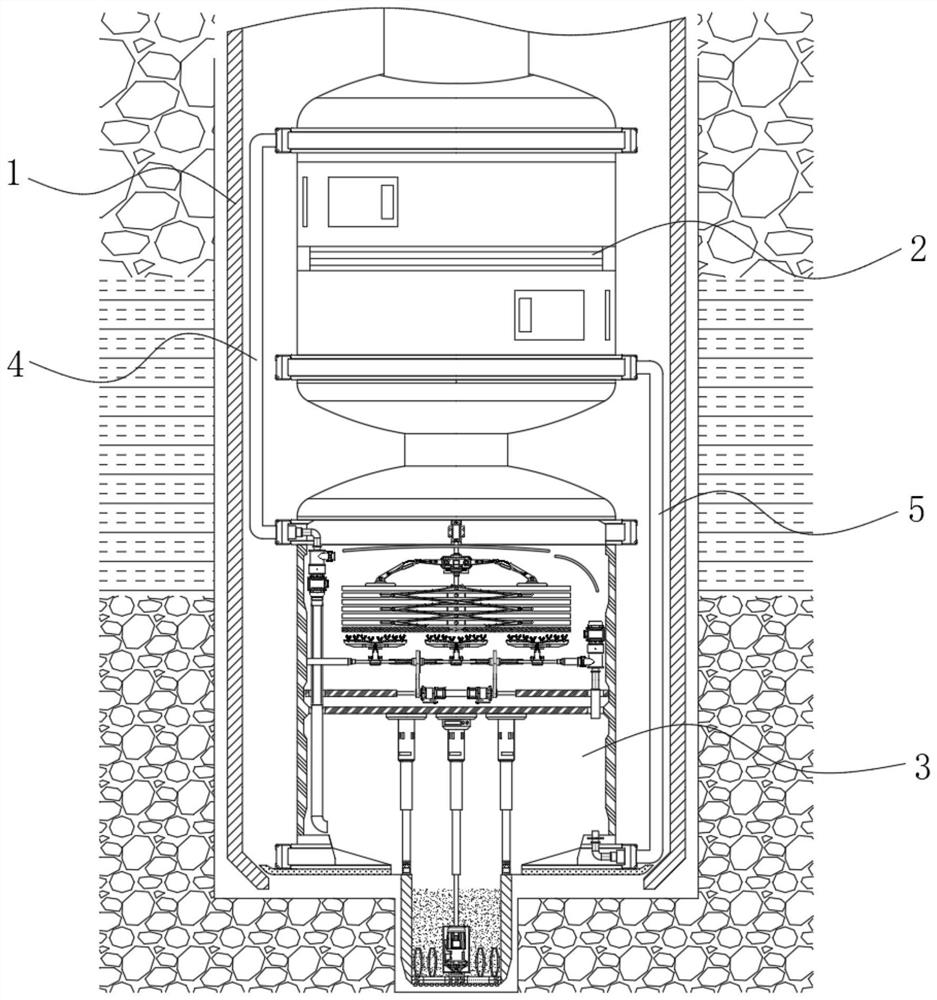

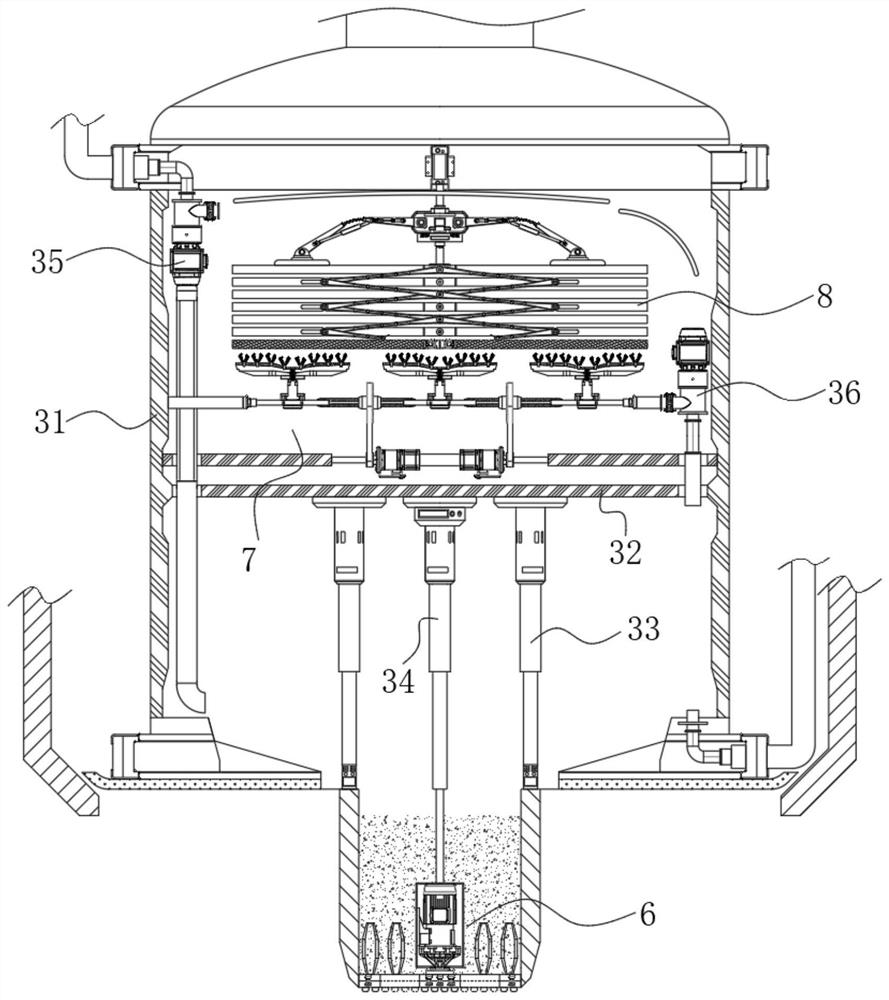

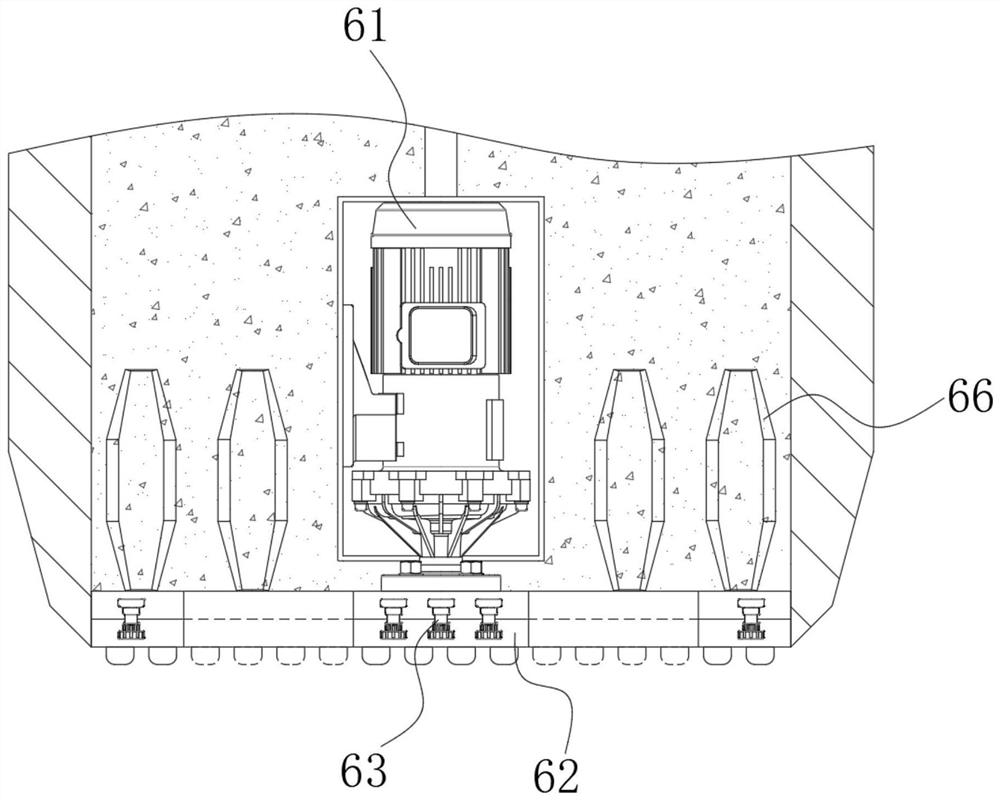

[0032] refer to figure 1 , 2 , the present invention provides a technical solution: a high-rank coal seam free gas content measuring device, which includes a drill pipe 1, a pressure supplement purification tank 2, a sampling measurement device 3, a conduit one 4 and a conduit two 5, the drill pipe 1 is equipped with a pressure-increasing purification tank 2 that can be stretched up and down, and the interior of the pressure-increasing purification tank 2 is independently divided into an upper pressure-increasing tank and a lower purification tank. The lower end of the pressure-increasing purification tank 2 is coaxially equipped with a measuring tank 31, the inside of the measuring tank 31 is provided with a sampling and measuring device 3, the upper and lower ends of the conduit one 4 communicate with the pressure boosting tank and the upper left end of the measuring tank 31 respectively, and the upper and lower ends of the conduit two 5 respectively communicate with the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com