A network wiring device

A technology for network wiring and installation, which is applied to instruments, fiber mechanical structures, optics, etc., and can solve the problems of accuracy, timeliness and simplicity of line maintenance, inability to adjust lines, and complicated manual operations, reducing labor costs. Installation error, improve work efficiency, reduce the effect of manual process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

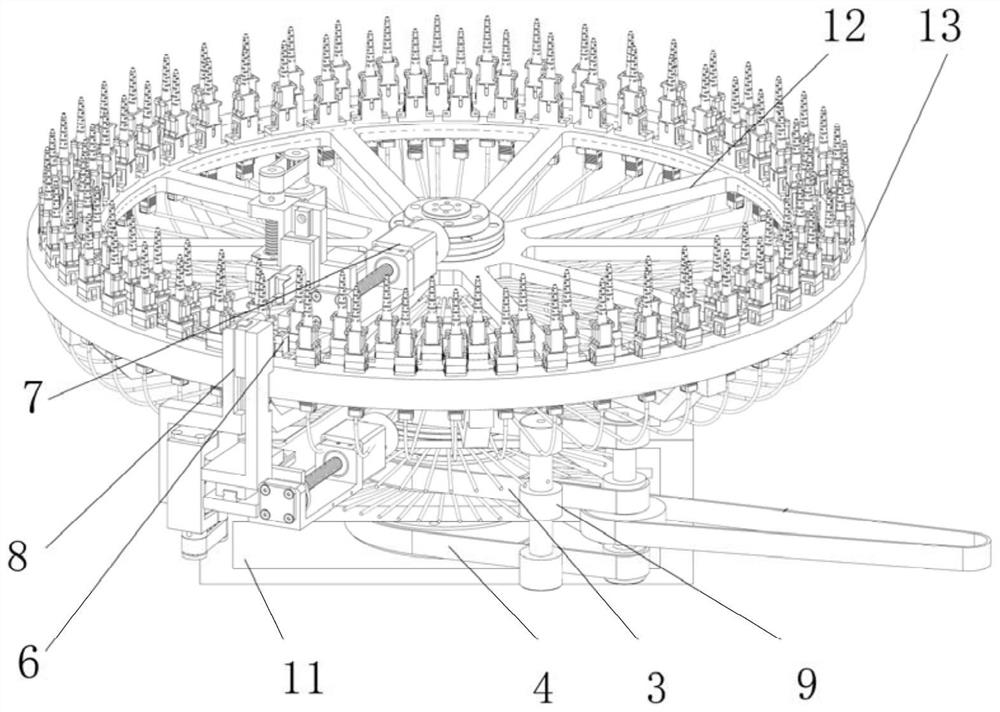

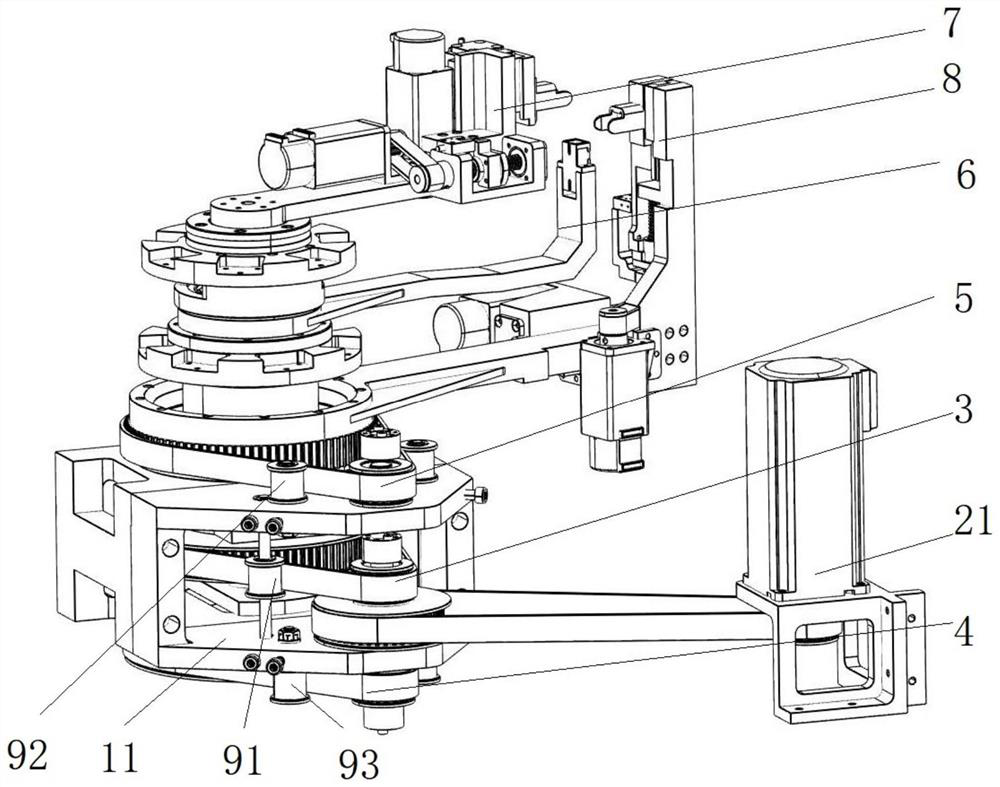

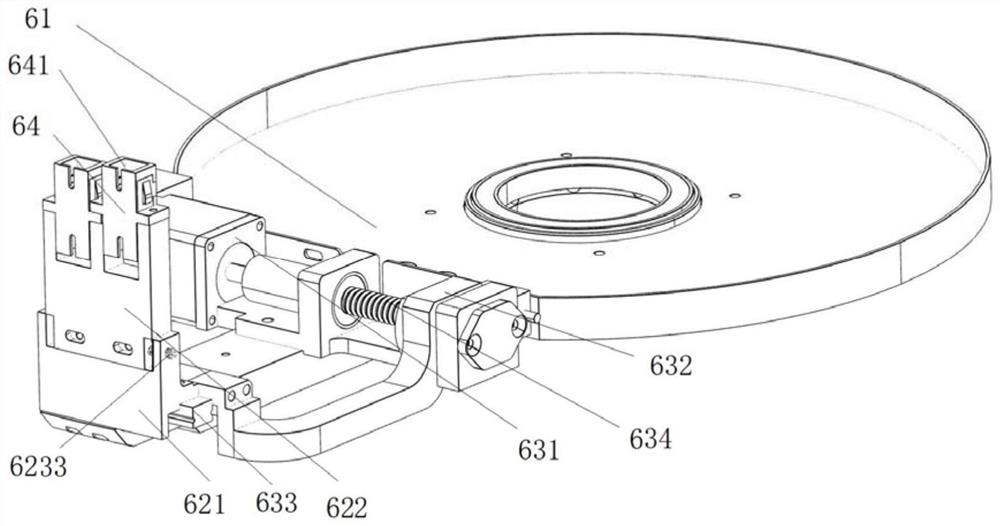

[0108] A network wiring device includes: a base frame assembly, a driving mechanism, a hand-reversing mechanism 6 , an inner layer grabbing mechanism 7 and an outer layer grabbing mechanism 8 . The base frame assembly includes: a base frame body 11 , an inner layer support 12 and an outer layer support 13 , the inner layer support 12 and the outer layer support 13 are fixedly installed on the base frame body 11 , and the inner layer support The bracket 12 is provided with a plurality of inner terminal mounting portions 121 suitable for mounting terminals, and the outer bracket 13 is provided with a plurality of outer terminal mounting portions 131 suitable for mounting terminals; the driving mechanism includes: a rotary driver 21, a reverse hand The transmission structure 3, the inner transmission structure 4 and the outer transmission structure 5, the rotary drive 21 drives the transmission of the inner transmission structure 4, the inverted transmission structure 3 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com