Fuzz button connector capable of crimping wire

A technology of hair buttons and connectors, applied in the field of electrical connectors, can solve the problems of large insertion force, inability to guarantee long-term multiple insertion and use, and small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

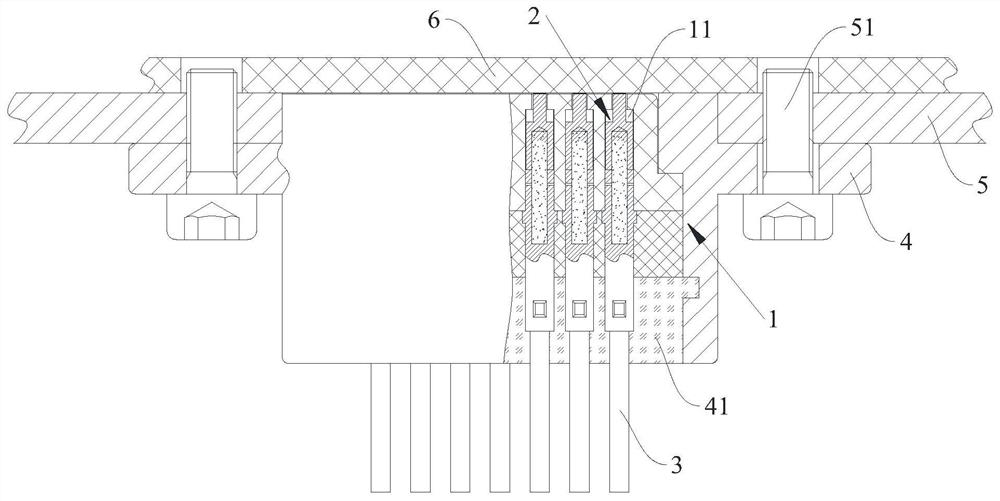

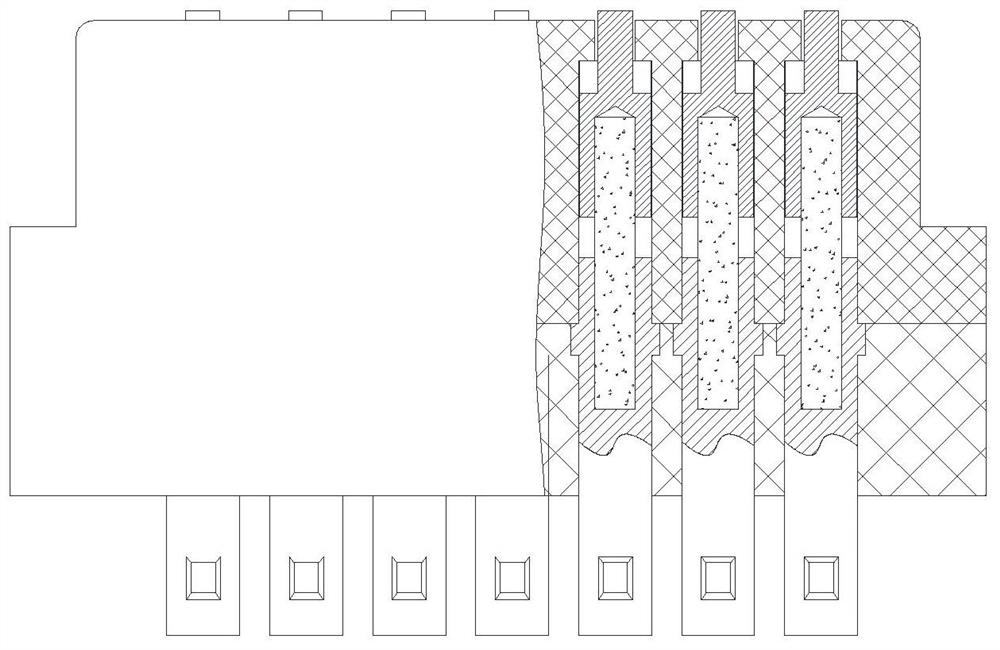

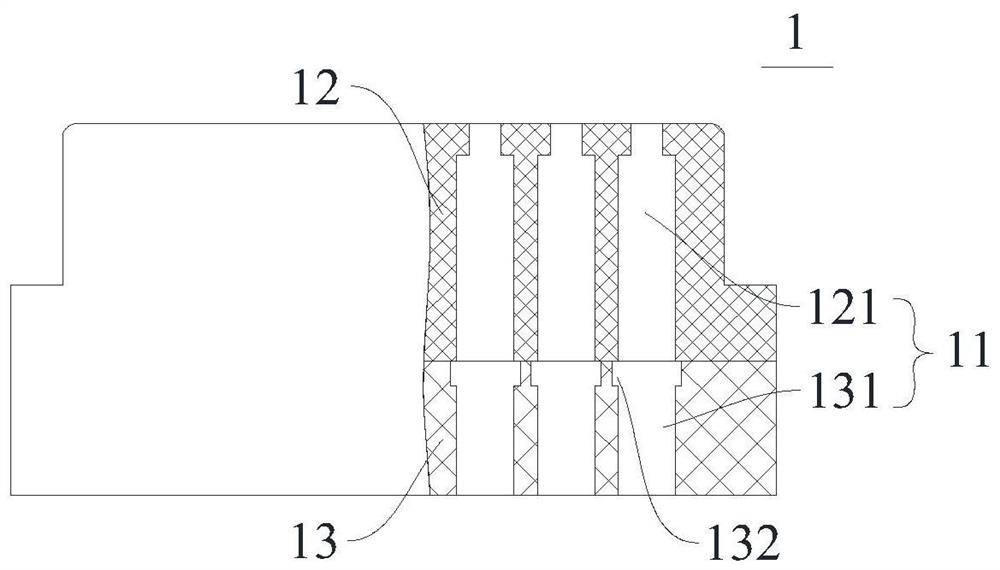

[0029] Such as figure 1 As shown, this embodiment provides a button connector capable of crimping wires, which includes: an insulating mounting assembly 1, in which a number of insertion holes 11 are provided; and a number of button contacts 2, which are respectively inserted in the Correspondingly inserted into the through hole 11, and the receiving end of the fur button contact 2 protrudes through the insertion through hole 11; and the other end of each of the fur button contact 2 is crimped with a wire 3; wherein the printed board 6 After pressing down the receiving end of the button contact 2, the signal on the printed board 6 is transmitted to the wire 3 through the button contact 2.

[0030] In this embodiment, by setting the button contact 2 in the insertion hole 11 of the insulating mounting assembly 1, the receiving end of the button contact 2 protrudes from the insertion hole 11, and then passes through the printed board 6 Press down on the receiving end to transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com