Coke powder removing system for pre-calcined needle coke

A technology of needle coke and coke powder, which is applied in the field of green coke processing, can solve the problems of affecting product indicators, reducing yield, increasing needle coke burning loss, etc., and achieves the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention is described in more detail to facilitate understanding of the present invention.

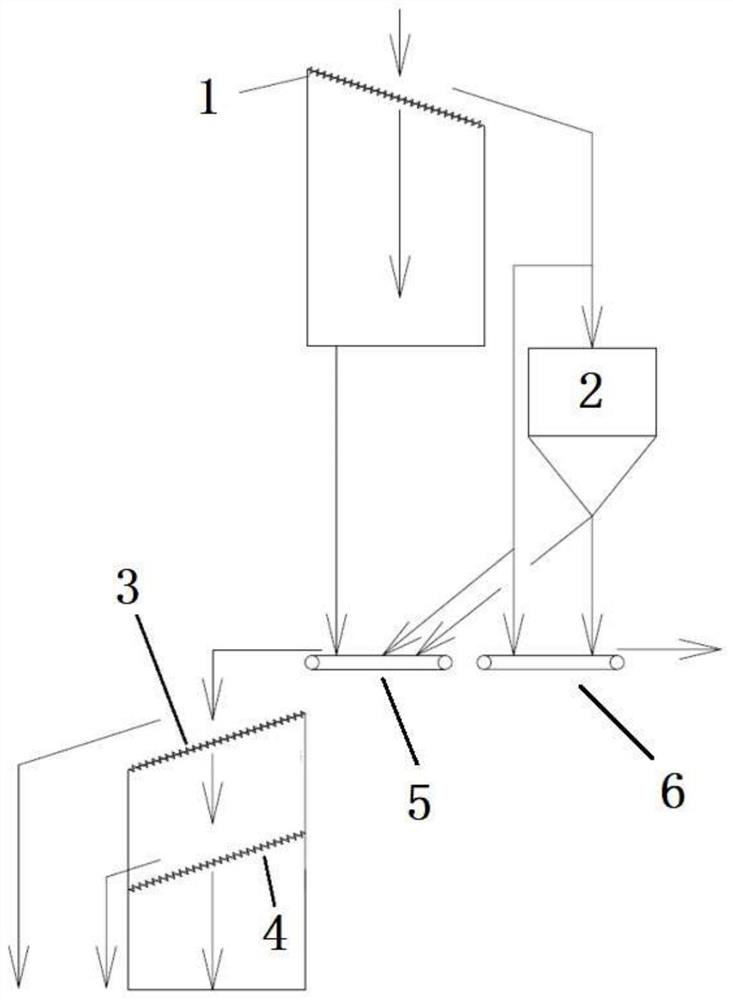

[0022] Such as figure 1 As shown, the needle coke decoking powder system before calcining according to the present invention includes a first vibrating screen 1, a crusher 2, a second vibrating screen 3, a third vibrating screen 4, a first conveyor belt 5 and a second conveyor belt 6, The first vibrating sieve 1 is used to divide the green coke with the first particle size into the green coke with the second particle size and the green coke with the third particle size; The green coke with the second particle size is transported to the first conveyor belt 5; a part of the green coke with the third particle size is transported to the second conveyor belt 6, and the other part is transported to the second conveyor belt 6. transported to the crusher 2; part of the raw coke processed by the crusher 2 is transported to the first conveyor belt 5, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com