Intelligent logistics sorting system based on infrared imaging image recognition and sorting method thereof

An image recognition and intelligent logistics technology, applied in the field of intelligent logistics sorting systems, can solve the problems of high production cost of RFID tags, unsuitable for large-scale popularization and harsh imaging conditions, etc., and achieves low use cost and is suitable for large-scale The effect of popular application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

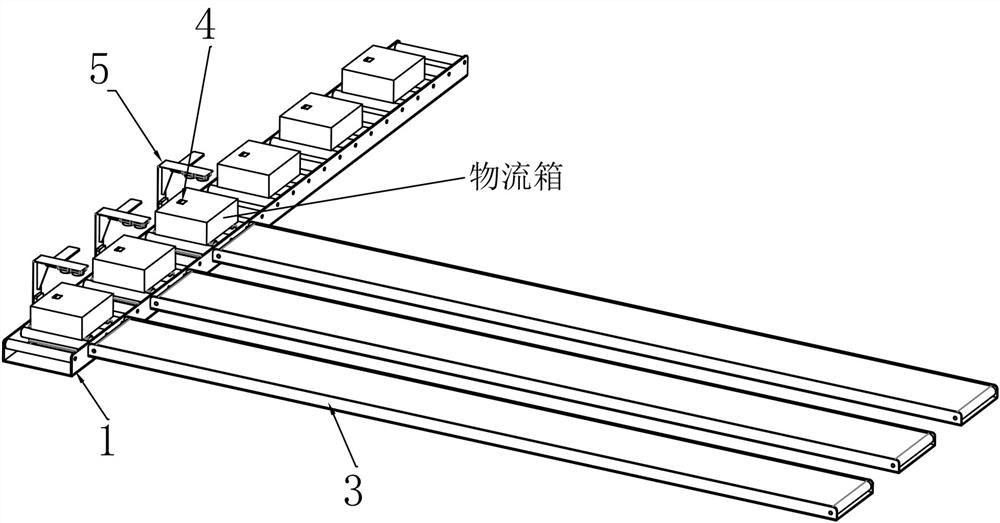

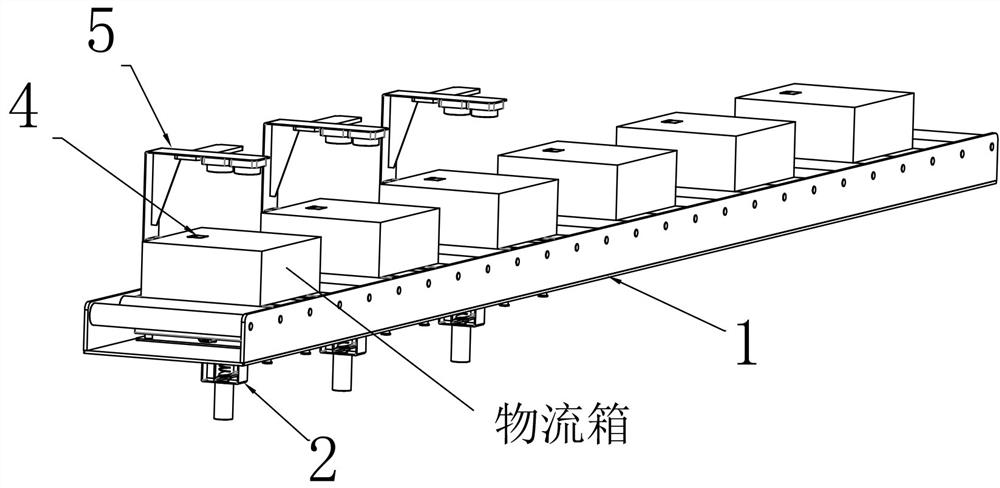

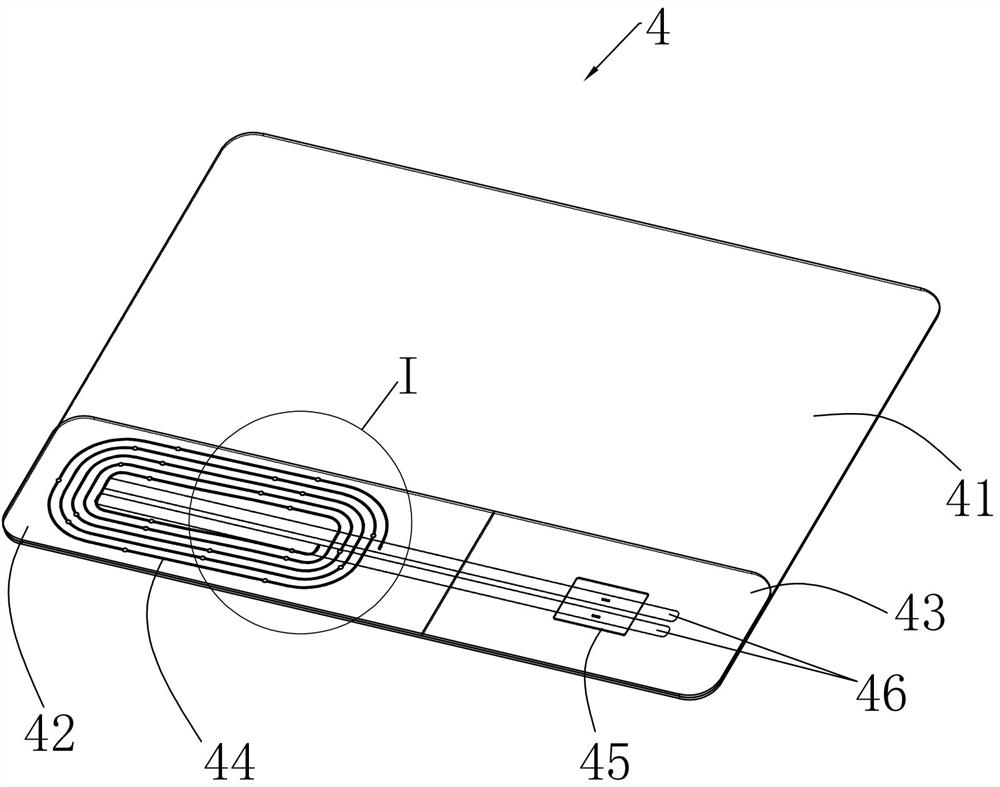

[0026] Such as Figure 1 to Figure 7 As shown, a kind of intelligent logistics sorting system based on infrared imaging image recognition described in this embodiment includes a feeding conveying roller mechanism 1 for conveying logistics boxes, and a plurality of feed conveying roller mechanisms 1 arranged at intervals Overturning unloading mechanism 2, a plurality of discharge conveying mechanisms 3 arranged on the other side of the feed conveying roller mechanism 1 at intervals, used for magnetic induction labels 4 attached to the surface of the logistics box, arranged at intervals on the feed conveying roller mechanism 1 Multiple sorting and identification mechanisms 5 on one side;

[0027] The positions of the plurality of overturning and unloading mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com