Automobile brake disc grinding equipment

A brake disc and equipment technology, applied in the field of brake disc grinding, can solve the problems of brake disc surface rust, processing environment impact, waste of water resources, etc., to achieve the effect of preventing sewage cross-flow, improving contact effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

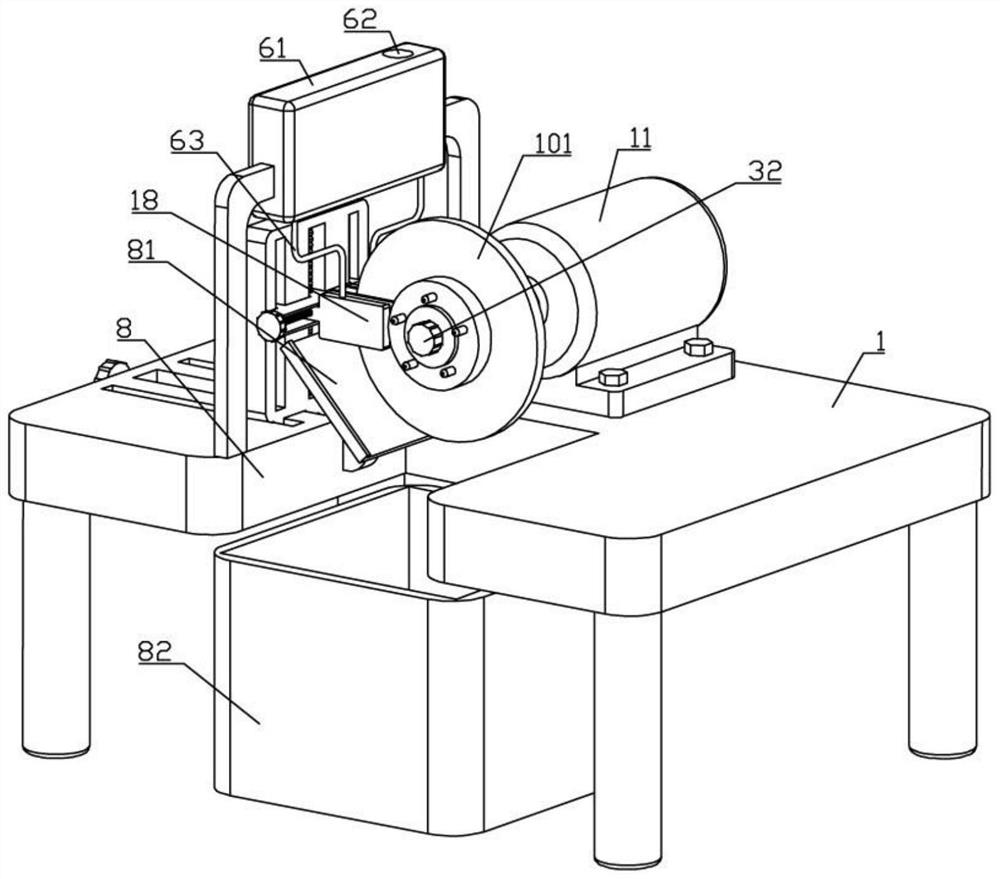

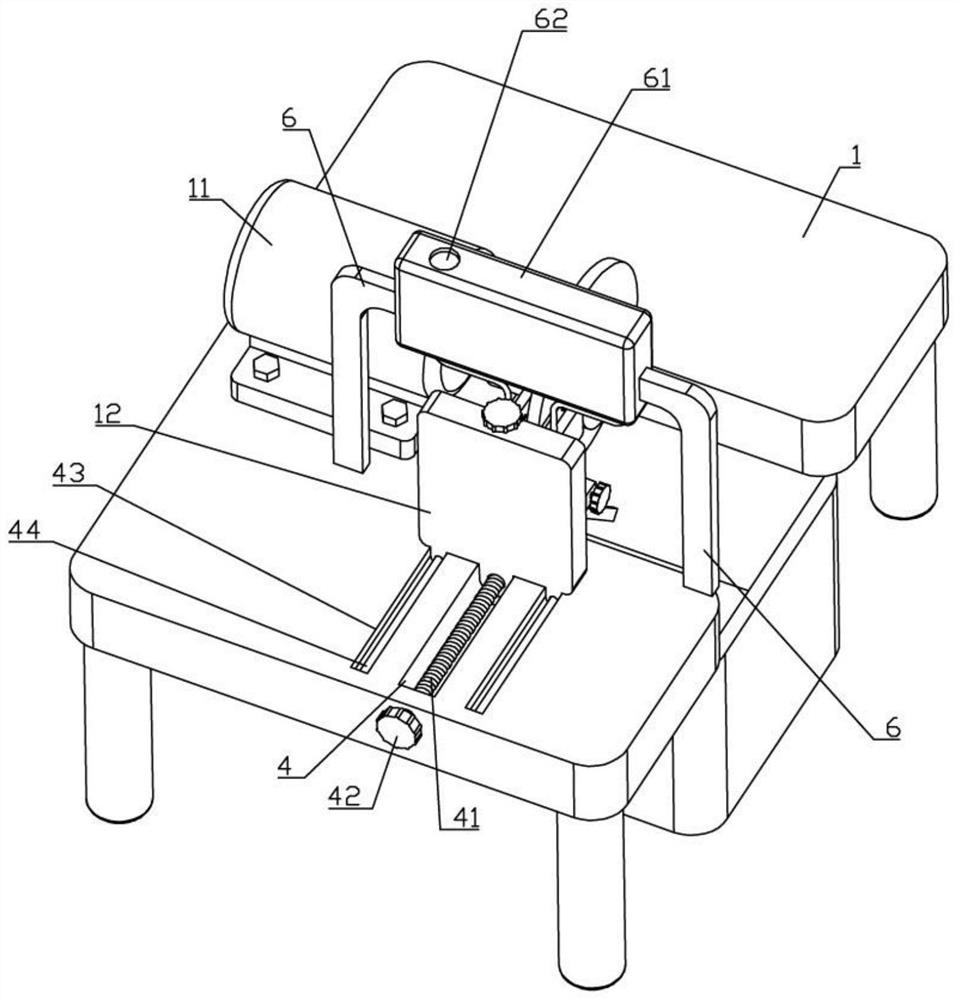

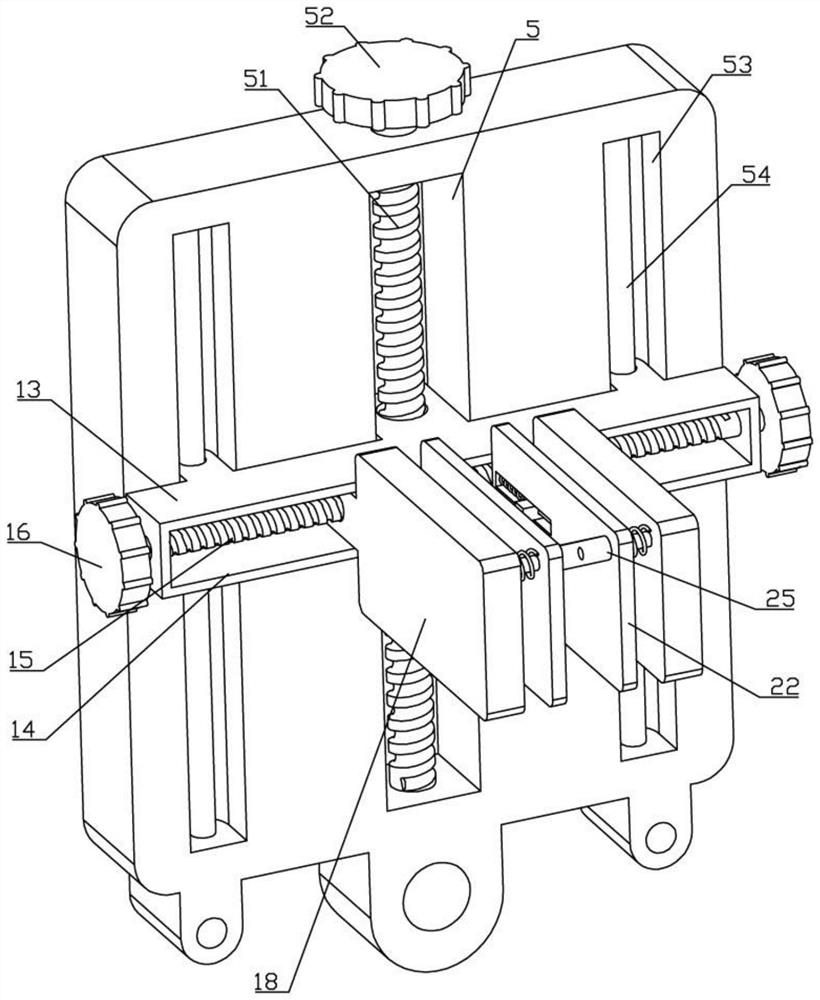

[0034] Such as Figure 1-7 As shown, a kind of automobile brake disc grinding equipment of the present invention includes a workbench 1 and a brake disc 101, a motor 11 is installed on the upper side of the workbench 1, and the output shaft transmission of the motor 11 is equipped with a mounting mechanism, and the brake disc 101 is assembled on the installation In terms of mechanism, the upper side of the workbench 1 is slidably equipped with a vertical plate 12, and the side of the vertical plate 12 facing the brake disc 101 is slid up and down to be equipped with a mounting bar 13, and the left and right sides of the mounting bar 13 are provided with chute 14, two chute 14 The first screw rods 15 are installed in the inner rotation, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap