Transverse arc-shaped bulkhead anti-explosion protection structure for broadside of ship

A technology of protective structure and curved cabin, applied in the direction of hull bulkhead, hull, hull parts, etc., can solve the problem of low energy absorption efficiency of the upper and lower ends, and achieve the effect of improving protection efficiency, enhancing impact resistance and flexible layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

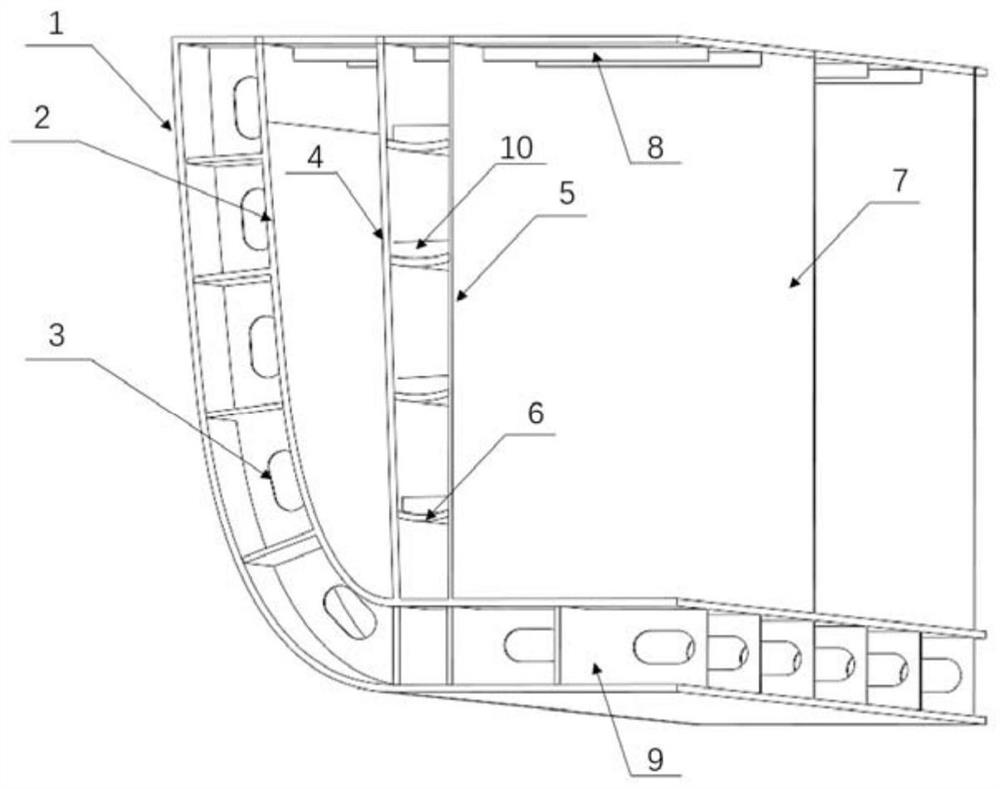

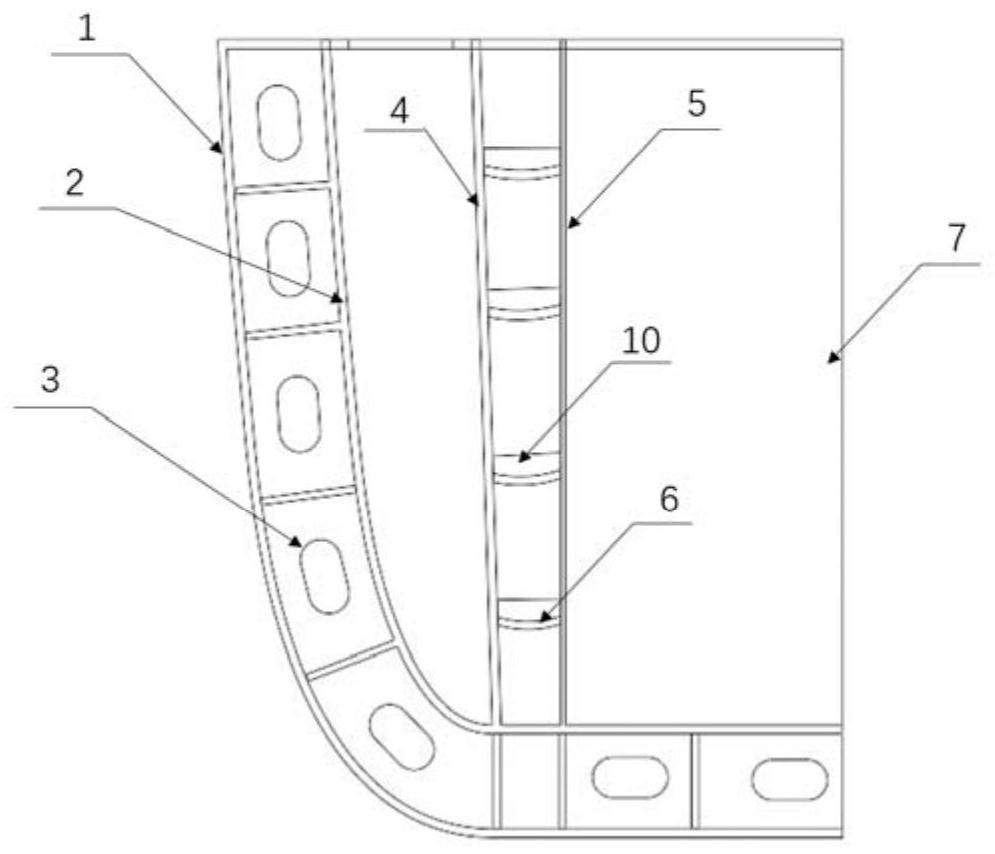

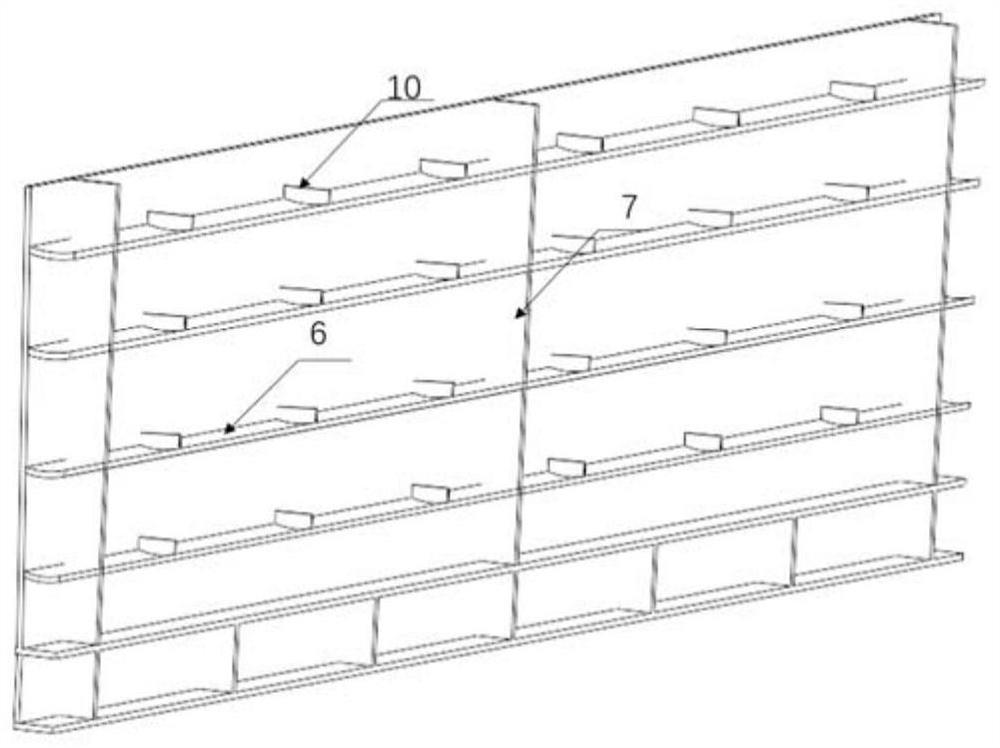

[0019] see Figure 1-4 Description of this embodiment, a transverse arc-shaped bulkhead anti-explosion protection structure on the side of a ship, is characterized in that it includes a liquid tank inner plate 4 connected between the bulkheads, a watertight bulkhead 5 and an arc-shaped plate 6. The number of arc-shaped plates 6 is multiple, and the arc-shaped plates 6 are welded between the liquid tank inner plate 4 and the watertight bulkhead 5 for wiring, and are arranged transversely along the ship's length direction, and the ends are connected with the transverse bulkhead 7. The inner plate 4 and the watertight bulkhead 5 are integrally welded to the outer plate 2 of the liquid tank, and the outer plate 2 of the liquid tank is connected to the outer plate 1 of the cabin sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com