Knock-resistant and impact-resistant multi-level heterogeneous fiber preform composite material and preparation method thereof

A composite material and impact-resistant technology, which is applied in the field of materials to achieve the effects of saving cost, improving shear and tear resistance, and improving anti-explosion and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

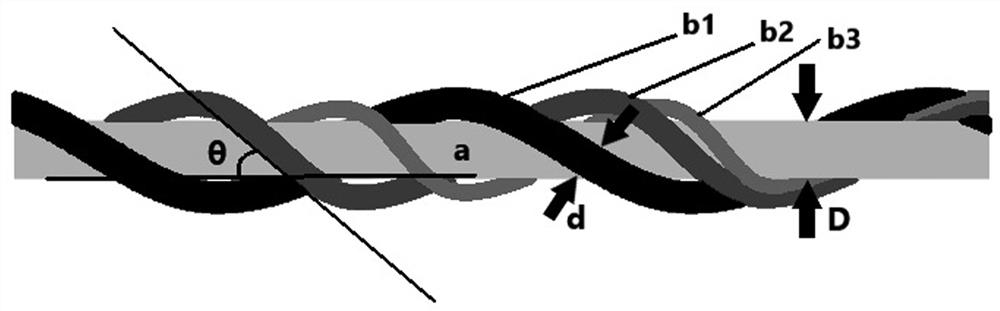

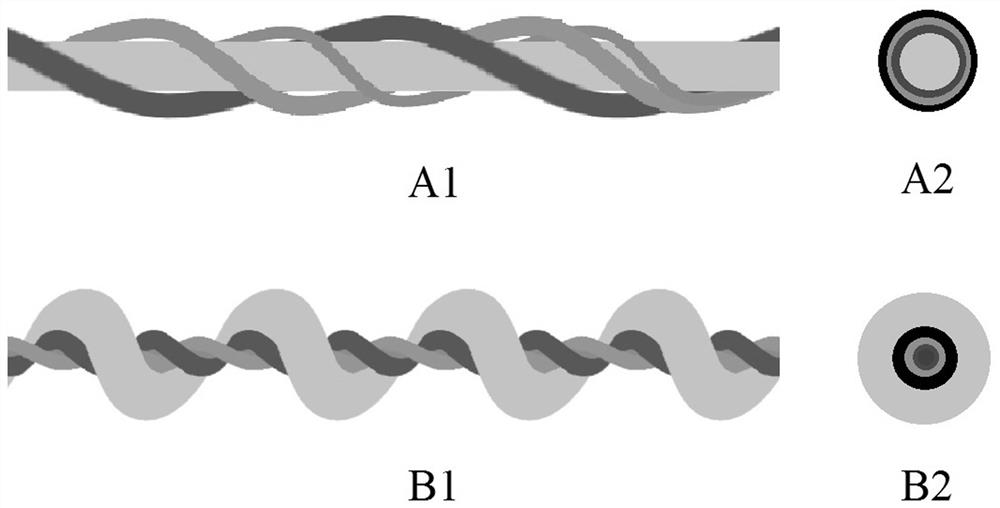

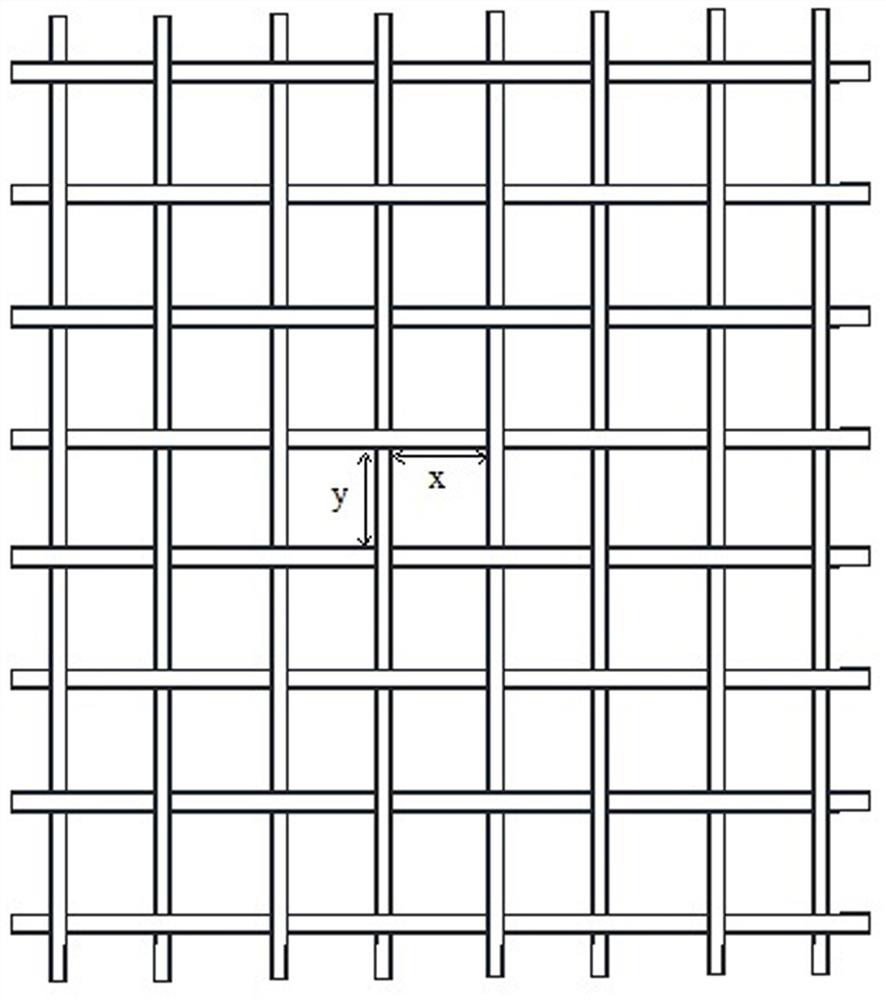

Method used

Image

Examples

Embodiment 1

[0028] The anti-explosion and impact-resistant composite material includes a base material and an anti-explosion and impact-resistant coating covering the base material. The substrate is concrete. The anti-knock and impact-resistant coating is formed by curing the coating applied on the substrate, and the coating is an epoxy resin that adds hydroxylated graphene and is fully dispersed; the weight of the hydroxylated graphene in the coating is The score is 0.4%. Two layers of parallel heterogeneous fiber preforms are arranged in the anti-explosion and anti-impact coating. The projection angle of the multi-level heterogeneous fibers between the adjacent layers of the two-level heterogeneous fiber preforms is 5 projections. The included angle between the plane where each layer of secondary heterogeneous fiber preform is located and the direction of the impact load resisted by the coating is 60°. The interlayer distance between adjacent secondary heterogeneous fiber preforms is...

Embodiment 2

[0038] The anti-explosion and impact-resistant composite material includes a base material and an anti-explosion and impact-resistant coating covering the base material. The substrate is ceramic. The anti-knock and impact-resistant coating is formed by curing the coating applied on the base material, and the coating is polyurea with hydroxylated graphene added and fully dispersed; the weight fraction of the hydroxylated graphene in the coating is 0.5%. Three layers of three-level heterogeneous fiber preforms arranged in parallel are arranged in the anti-explosion and anti-impact coating. The projection angle of the multi-level heterogeneous fibers between adjacent layers of three-level heterogeneous fiber preforms is 15°. The included angle between the plane where the three-level heterogeneous fiber preform of each layer is located and the direction of the impact load resisted by the coating is 46°. The interlayer distance between the adjacent tertiary heterogeneous fiber p...

Embodiment 3

[0048] The anti-explosion and impact-resistant composite material includes a base material and an anti-explosion and impact-resistant coating covering the base material. The base material is low carbon steel. The anti-knock and impact-resistant coating is formed by curing the coating coated on the substrate, and the coating is polyurethane that is fully dispersed by adding hydroxylated graphene; the weight fraction of the hydroxylated graphene in the coating is 0.8%. Four layers of four-level heterogeneous fiber preforms arranged in parallel are arranged in the anti-explosion and anti-impact coating. The projected angle of the multi-level heterogeneous fibers between the adjacent four-level heterogeneous fiber preforms of each layer is 35°. The angle between the plane where the four-level heterogeneous fiber preform of each layer is located and the direction of the impact load resisted by the coating is 90°. The layer spacing between adjacent four-level heterogeneous fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com