Double-steel plate composite shear wall with external compression and tension-free concrete embedded with damping interlayer

A combination of shear walls and outsourcing concrete technology, applied in the direction of walls, earthquake resistance, fire prevention, etc., can solve the problems of explosion resistance, impact resistance, and lack of high bearing capacity, so as to improve the anti-explosion and impact performance and maintenance cost Low, the effect of improving the seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

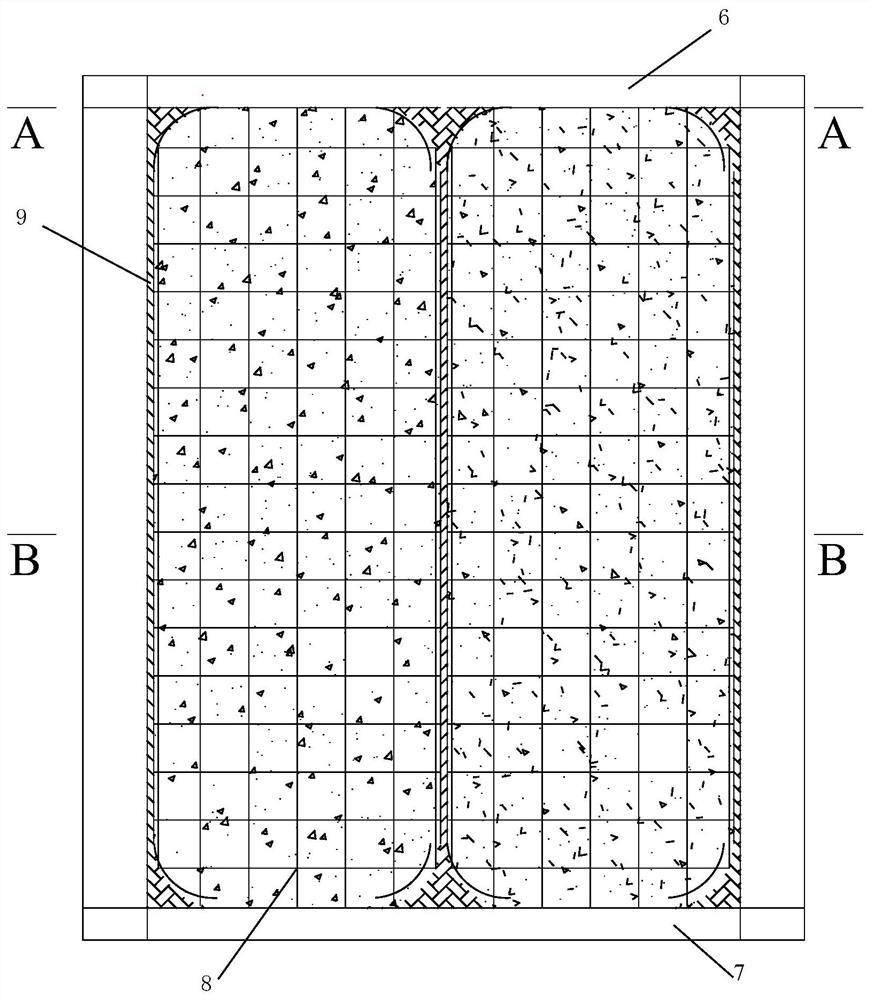

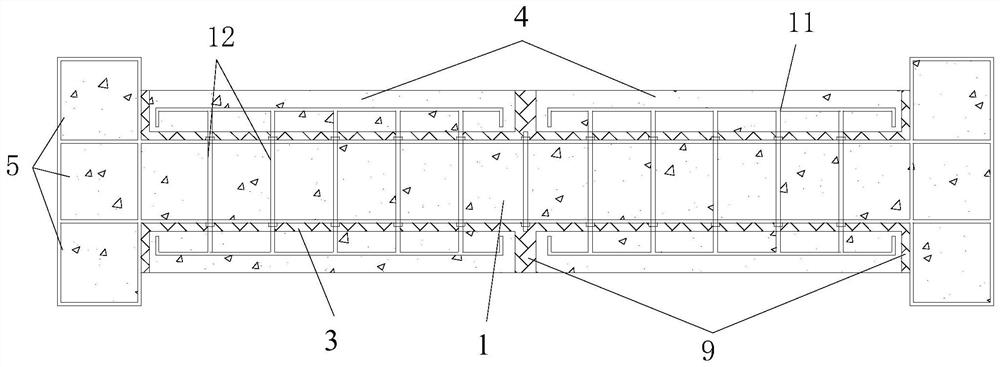

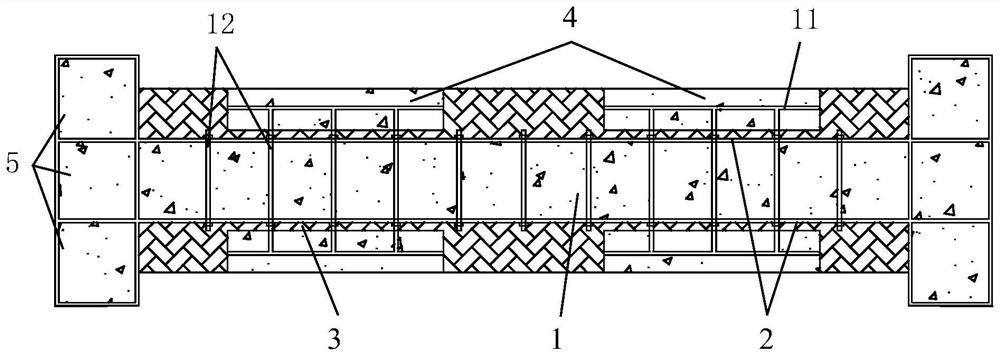

[0035] Such as Figure 1-3 As shown, a double-steel composite shear wall with a pressure-resistant and untensioned concrete embedded damping interlayer in the present invention includes a concrete core layer 1, a steel plate layer 2, a damping interlayer 3, and an outer concrete layer from the inside to the outside. Layer 4, the two sides of the steel plate layer are respectively connected with steel tube concrete beams 5, and a concrete core is poured between the steel plate layer and the steel tube concrete beams, and the outsourcing is a double steel plate combined shear wall with a pressure-resistant concrete embedded with a damping interlayer It also includes a top plate 6 and a bottom plate 7 welded to the top and bottom of the wall respectively.

[0036] The steel plate layer includes two parallel steel plates. The damping interlayer includes two parallel damping interlayers, and the damping interlayer is located between the steel plate layer and the outer concrete lay...

Embodiment 2

[0046] Such as Figure 4 As shown, the thickness of the CFST bundles on both sides is equal to the thickness of the wall, that is, the thickness of the outsourcing concrete + the thickness of the damping interlayer is equal to the thickness of a single CFST bundle unit. This design has a regular shape for easy assembly.

[0047] All the other technical features are the same as in Embodiment 1.

[0048] Assembly method of the present invention comprises the following steps:

[0049] a. Weld and connect the steel plate layer with the section steel of the steel tube concrete bundle, install and fix the wall restraint tie rod assembly, that is, pass the restraint tie rod through the wall, tighten the nut, pour concrete in the cavity of the steel plate and the section steel, and complete the double steel plate concrete shear Fabrication of force walls and concrete-filled steel tube bundles;

[0050] b. Apply adhesive on the outside of the steel plate layer to firmly bond the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com