Anti-explosion and anti-shock multi-stage heterogeneous fiber precast composite concrete and its preparation method

A prefabricated body and concrete technology, applied in the direction of chemical instruments and methods, manufacturing tools, hydraulic material layered products, etc., can solve the problems of inability to achieve concrete impact resistance, negative Poisson's ratio effect is not obvious, and fiber cannot be applied Concrete and other problems to achieve the effect of improving three-dimensional random distribution, reducing secondary damage, and improving compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

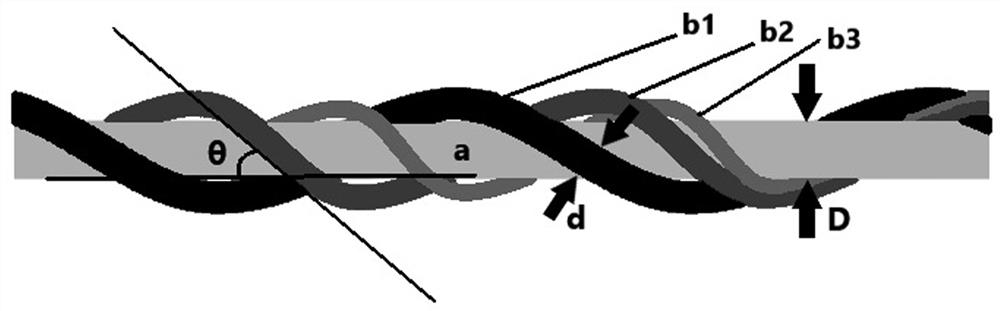

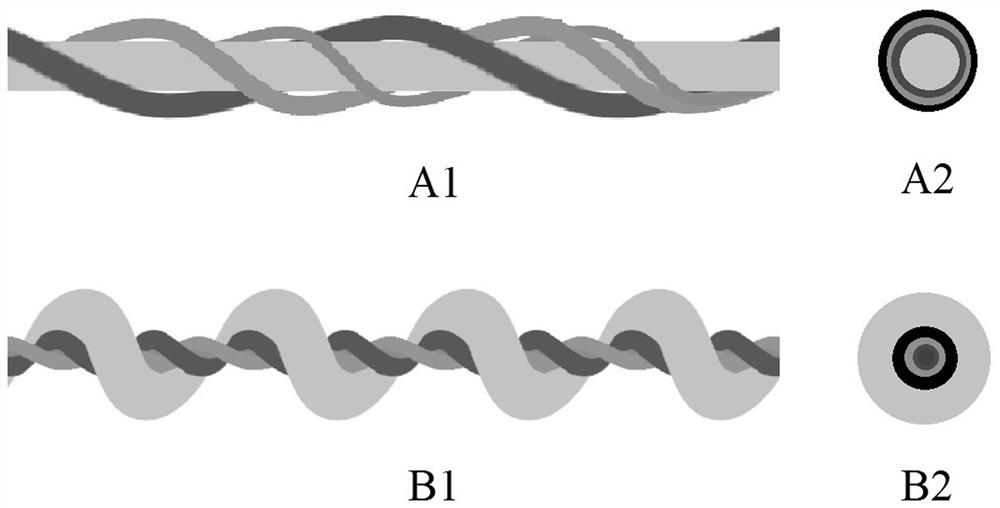

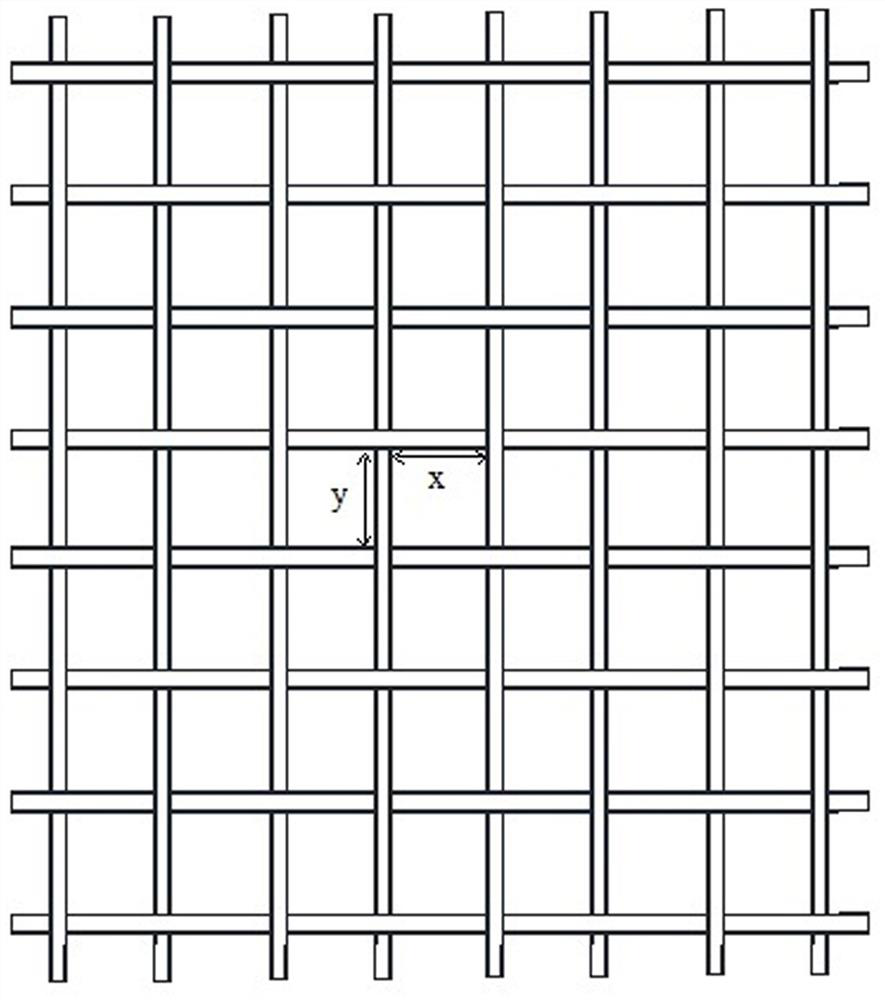

[0028] The secondary heterogeneous fiber prefabricated body with negative Poisson's ratio effect is formed by weaving several secondary heterogeneous fibers in warp and weft. The secondary heterogeneous fiber is formed by winding multi-level auxiliary fibers on the core fiber; the core fiber is a low modulus fiber, and the secondary auxiliary fiber is a high modulus fiber with different elastic modulus. The distance between the core fibers of adjacent secondary heterogeneous fibers is 20mm. Described low modulus fiber is polyvinyl alcohol fiber; Polyvinyl alcohol fiber: long fiber, diameter is the fiber bundle of 450 μm, elongation at break is 7%, modulus of elasticity is 43GPa, and density is 1.30g / cm 3 , has good acid and alkali resistance.

[0029] The primary auxiliary fiber is an aramid fiber with an elastic modulus of 50 GPa, a diameter of 150 μm, and a helix angle of 6°; the second-level auxiliary fiber is an aluminum silicate fiber with an elastic modulus of 480 GPa a...

Embodiment 2

[0037] Embodiment 2: Different from Embodiment 1,

[0038] For the three-level heterogeneous fiber preform with negative Poisson's ratio effect, the distance between the core fibers of adjacent three-level heterogeneous fibers is 50 mm. Described low modulus fiber is polyethylene fiber; Polyethylene fiber: bundle monofilament, diameter is the fiber bundle of 380 μm, elastic modulus is 4000MPa, elongation at break is 15%, and density is 0.91g / cm 3 .

[0039] The first-level auxiliary fiber is aramid fiber with an elastic modulus of 85GPa, a diameter of 243 μm, and a helix angle of 7°; the second-level auxiliary fiber is an ultra-high molecular weight polyethylene fiber with an elastic modulus of 130GPa and a diameter of 151 μm, and the helix angle is 15°; the third-level auxiliary fibers are steel fibers and carbon fibers, wherein the elastic modulus of the steel fibers is 210 GPa, the elastic modulus of the carbon fibers is 200 GPa, and the diameters of the steel fibers and t...

Embodiment 3

[0047] Embodiment 3: Different from Embodiment 1,

[0048] For the four-level heterogeneous fiber preform with negative Poisson's ratio effect, the distance between the core fibers of adjacent four-level heterogeneous fibers is 80 mm. Described low modulus fiber is polypropylene fiber; Polypropylene fiber: bundle-shaped monofilament long fiber, diameter is the fiber bundle of 410 μm, and density is 0.91g / cm 3 , elastic modulus of 3500MPa, elongation at break of 17%, flexible chain fiber, strong acid and alkali resistance.

[0049] The primary secondary fiber is a polyarylate fiber with a modulus of elasticity of 50Gpa, a diameter of 270 μm, and a helix angle of 5°; the secondary secondary fiber is a polybenzobisoxazole fiber with a modulus of elasticity of 56Gpa. The diameter is 220 μm, the helix angle is 12°; the third-level auxiliary fiber is ultra-high molecular weight polyethylene fiber, the elastic modulus is 65Gpa, the diameter is 143 μm, and the helix angle is 18°; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com