Modular lifting equipment and lifting system

A lifting device and a modular technology, applied in the field of climbing devices, can solve problems such as long working time, complex structure, and many installation procedures, and achieve the effects of broad market application prospects, strong environmental adaptability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

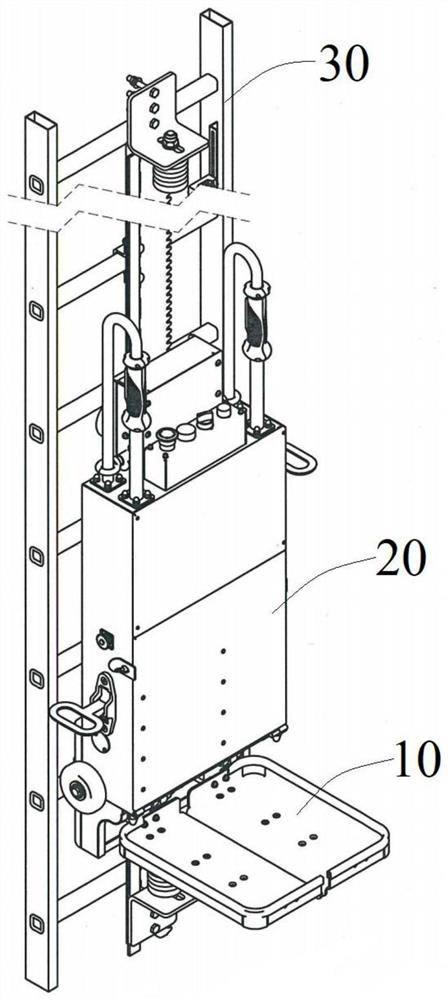

[0063] see Figure 1 to Figure 7 , this embodiment provides a modular lifting device, which is applied to a building or equipment ladder, and can run up and down along the track installed on the building or equipment ladder, and carry out high-altitude transportation of personnel and materials.

[0064] Such as figure 1 As shown, the modular lifting equipment includes a vehicle body assembly 10 and a drive control assembly 20, the drive control assembly 20 is detachably connected to the vehicle body assembly 10, and the vehicle body assembly 10 is transmission-connected to the guide body 30 (guide rail or track).

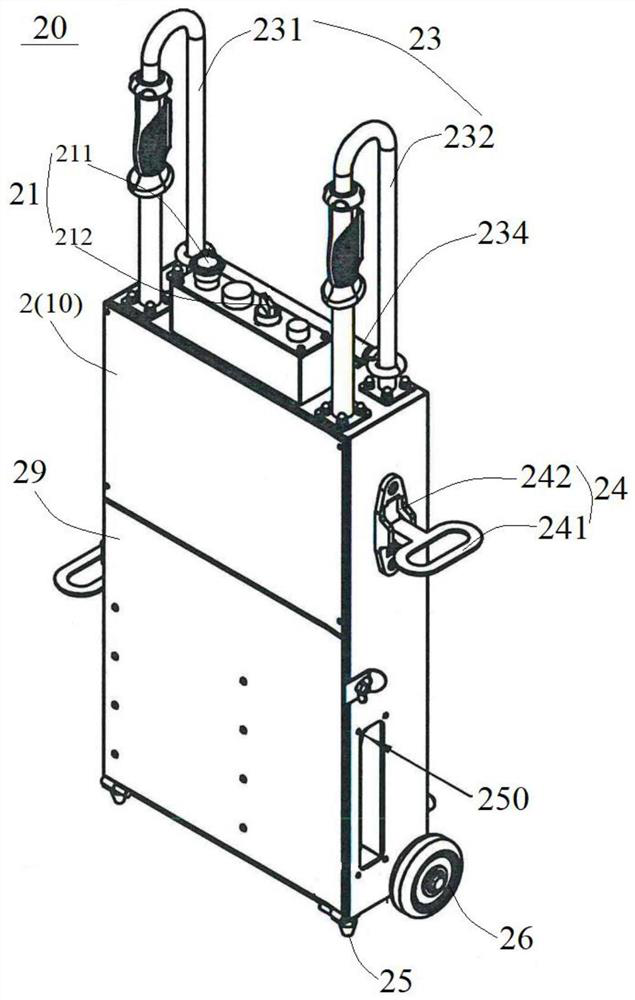

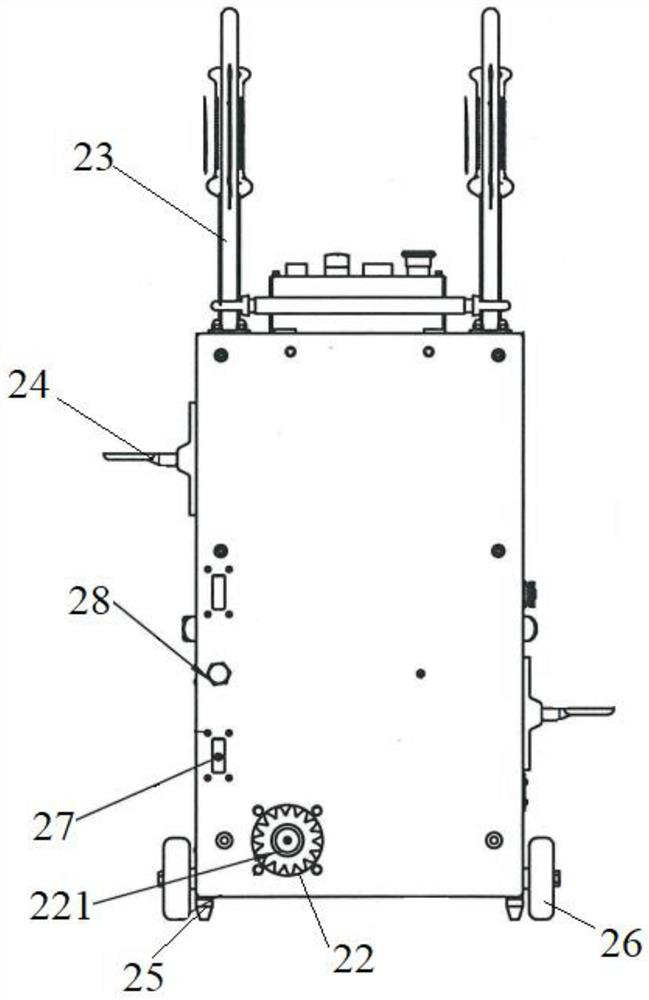

[0065] Such as figure 2 with image 3 As shown, the drive control assembly 20 includes a control assembly 21, a drive assembly 22, and an armrest assembly 23. The control assembly 21 is electrically connected to the drive assembly 22, and is used to control the modular lifting equipment to run on the guide body 30. The drive assembly 22 is used to It is used to...

Embodiment 2

[0097] see Figure 7 On the basis of the above-mentioned embodiment 1, the difference from the above-mentioned embodiment 1 is that the auxiliary guide assembly 13 further includes a deflecting wheel 132 , and the deflecting wheel 132 is located on the vehicle body 11 and opposite to the driving gear 221 . The deflection wheel 132 is used to constrain the relative positional relationship between the driving gear 221 and the guide body 30 to ensure that the driving gear 221 has a stable meshing dimension.

[0098] The vehicle body 11 is stabilized on the guide body 30 through the cooperation of the driving gear 221 and the deflection wheel 132 . When the driving gear 221 rotates, the deflection wheel 132 slides against the outer surface of the guide body 30 to keep the driving gear 221 and the guide body 30 in a meshing state all the time.

[0099] Such as Figure 7 As shown, the deflector wheel 132 is installed on the car body 11 through an adjustment member 133, and the adj...

Embodiment 3

[0103] see Figure 7 , on the basis of the above-mentioned embodiment 1 or embodiment 2, and different from the above-mentioned embodiment 1 or embodiment 2, the auxiliary guide assembly 13 further includes a guide hook wheel 134, and the guide hook wheel 134 is fixedly installed on the vehicle body body 11 In addition, during the operation of the lifting device along the guide body 30 , the guide hook wheel 134 can slide and / or roll in contact with the surface of the guide body 30 to further ensure the connection stability of the vehicle body 11 on the guide body 30 .

[0104] Specifically, the guide hook wheel 134 includes a wheel body and a support (not labeled in the figure) for installing the wheel body, the support is fixedly installed on the vehicle body 11, and the guide hook wheel 134 is mounted on the support by bearing rotation. superior. When the vehicle body 11 moves up and down on the guide body 30 , the guide hook wheel 134 can rotate around the support and sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com