Bolt connection assembly type L-shaped double-steel-plate concrete composite wall

A double steel plate and concrete technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of steel plate stress concentration, increase the difficulty of on-site construction, etc., and achieve the effect of improving efficiency, simple and easy connection method, and safe and reliable connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] as the picture shows:

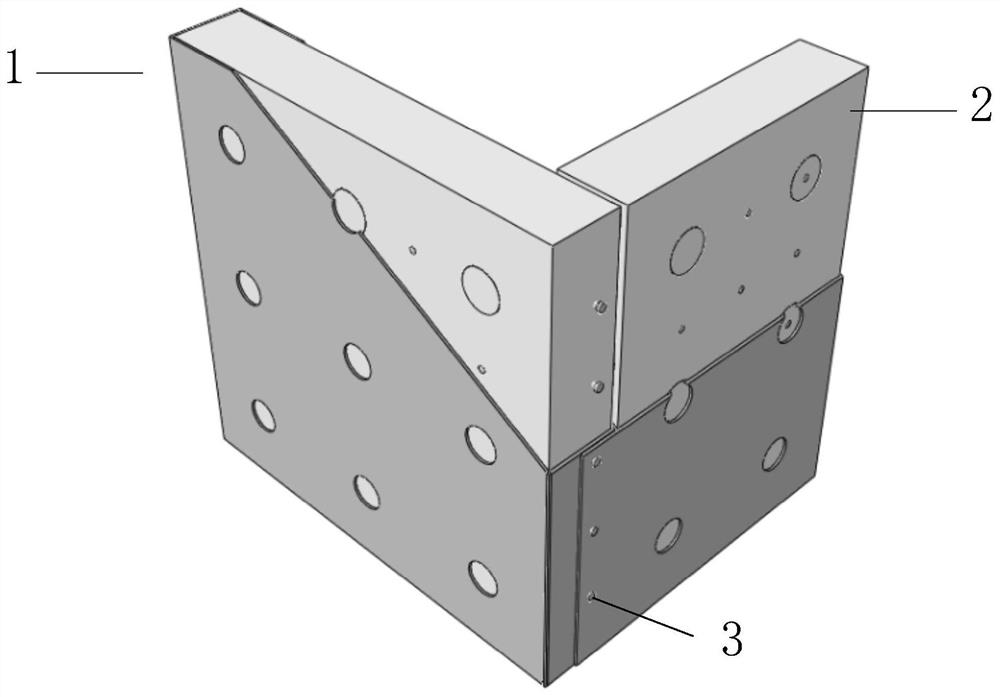

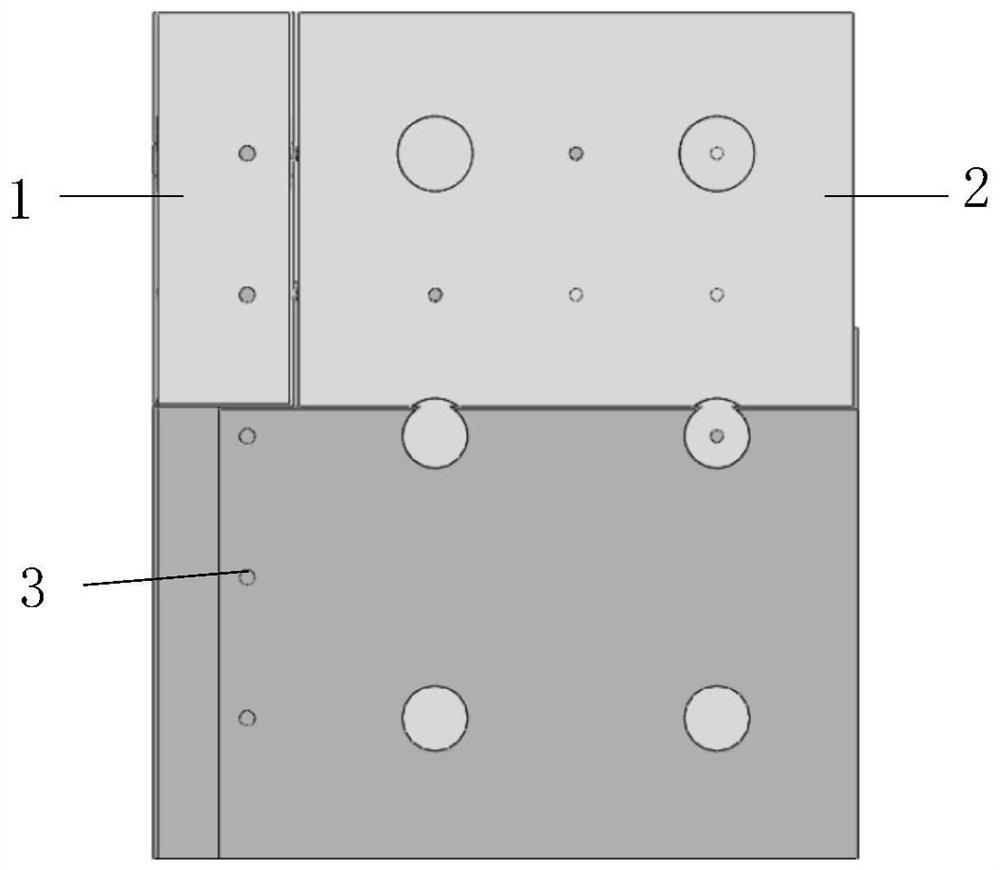

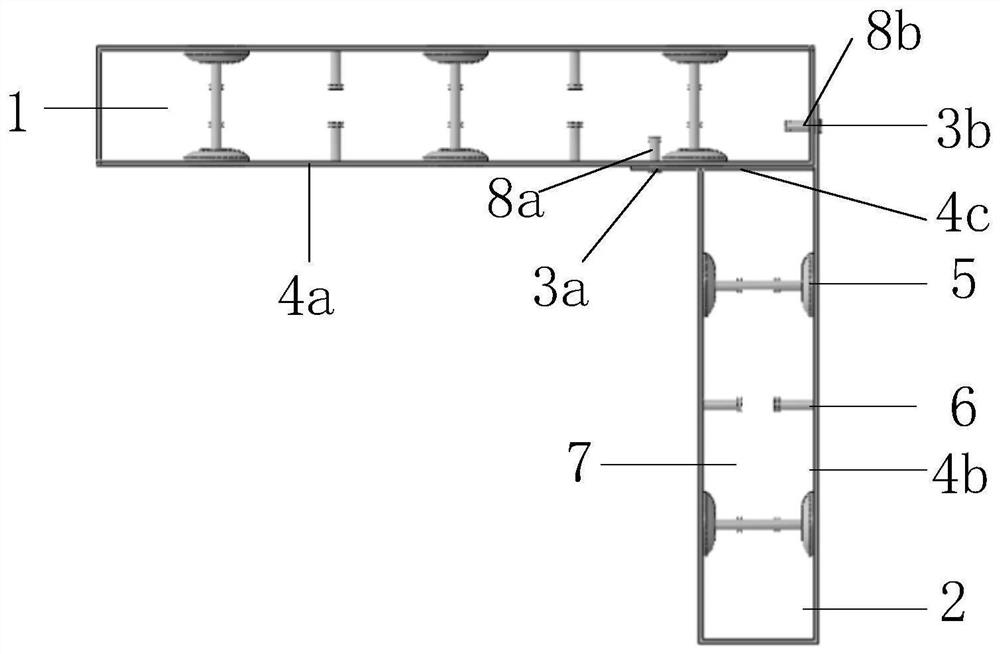

[0030] 1. A bolt-connected assembled L-shaped double-steel-plate concrete composite wall, comprising a double-steel-steel-concrete composite wall with dumbbell-shaped connection openings (hereinafter referred to as wall-1), and a dumbbell-shaped connection-opening double-steel-steel concrete composite wall Body two 2 (hereinafter referred to as body of wall two 2) and connecting bolt 3. The first wall 1 and the second wall 2 are perpendicular to each other, and are assembled into an L-shaped wall by connecting bolts 3 at the vertical connection of the two walls.

[0031] The first wall 1 and the second wall 2 include perforated double steel plates 4 , dumbbell-shaped connectors 5 , pegs 6 and filled concrete 7 .

[0032] The perforated double steel plate 4 of the wall body 1 is an integral double steel plate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com