Screw tap device for repairing internal thread

A technology of internal thread and tap, which is applied in the field of tap devices, and can solve the problems of long thread time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the inventive concept of the present invention will be described in detail with reference to the accompanying drawings. What is described here is only a preferred embodiment of the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention. In the following detailed description, directional terms such as "upper", "lower", "inner", "outer", "longitudinal", "horizontal" and the like are used with reference to the directions described in the drawings. Components of embodiments of the present invention may be positioned in a variety of different orientations, and directional terms are used for purposes of illustration and not limitation.

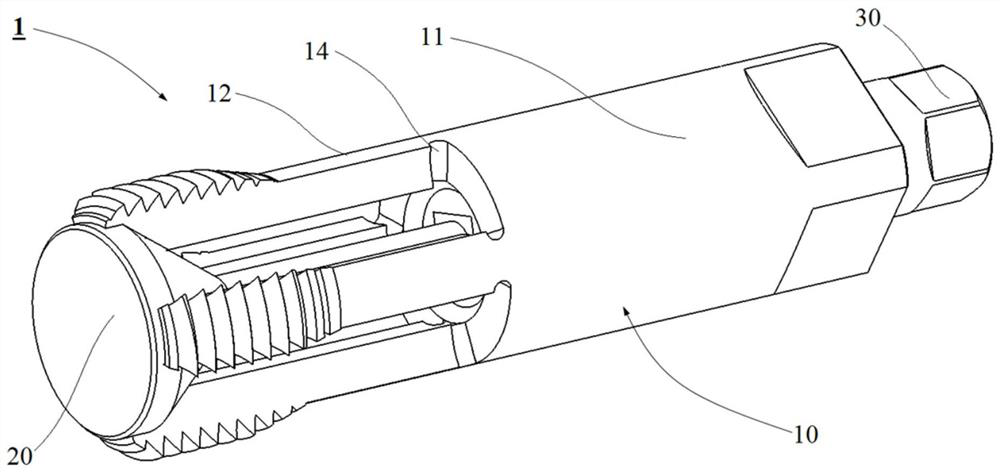

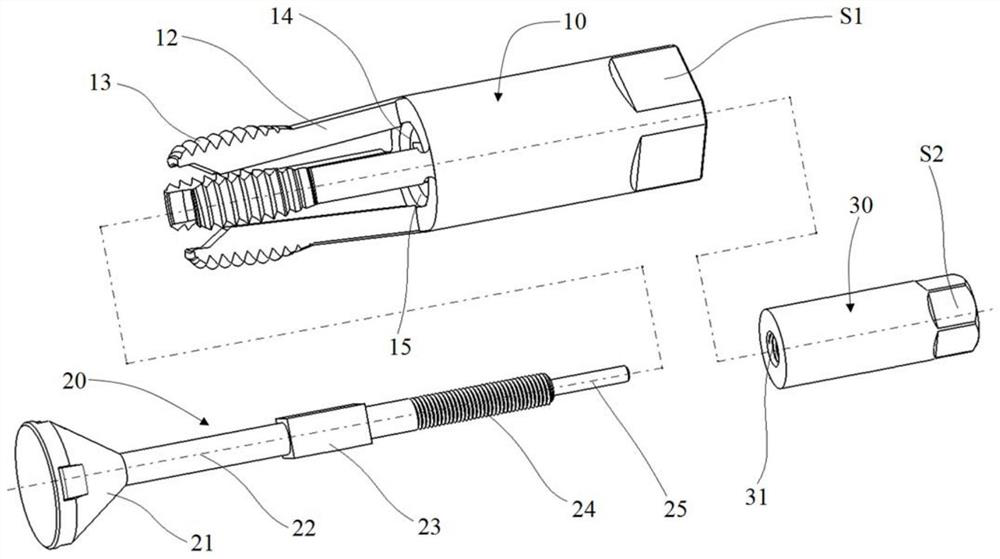

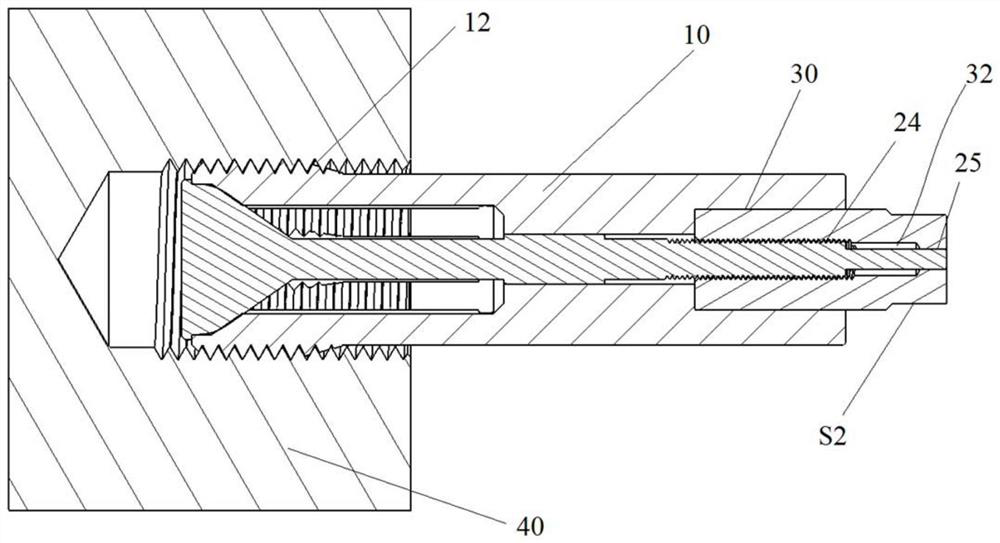

[0029] figure 1 A schematic diagram of the assembled tap device 1 is shown, figure 2 A schematic view of the tap device 1 before assembly is shown. see Figure 1-2 , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com