A kind of mandibular condyle osteochondral repair scaffold material and preparation method thereof

A scaffold material and osteochondral technology, applied in the direction of bone/connective tissue cells, prostheses, tissue regeneration, etc., can solve problems such as repair and inability to realize osteochondral defect of mandibular condyle, and achieve the effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, mercapto-hyaluronic acid (HA-SH) is prepared, and the steps are as follows:

[0041] (1) Dissolve 2 g of sodium hyaluronate (HA) with a molecular weight of 0.3 MDa in deionized water, add 10 mmol of N-hydroxysuccinimide (NHS), stir in deionized water at room temperature until completely dissolved, and then Add 25 mmol of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), fully dissolve, and adjust the mixing with 1 mol / L NaOH solution and 1 mol / L HCl solution The pH value of the solution was 4.75-5.0, reacted at room temperature for 2 hours, then added 25 mmol of cysteine hydrochloride (CSH·HCl), reacted at room temperature for 24 hours, and then transferred the solution to a dialysis bag with a molecular weight cut-off of 8000-14000 KDa, and kept at room temperature Dialysis was performed for 72 hours, and finally the dialysate was freeze-dried to obtain solid HA-SH.

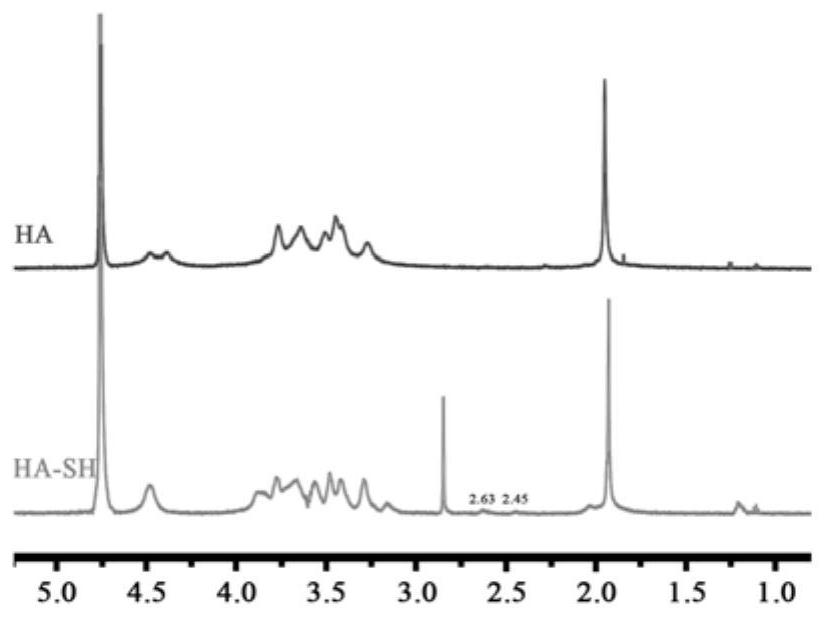

[0042] HA and HA-SH are detected by nuclear magnetic resona...

Embodiment 2

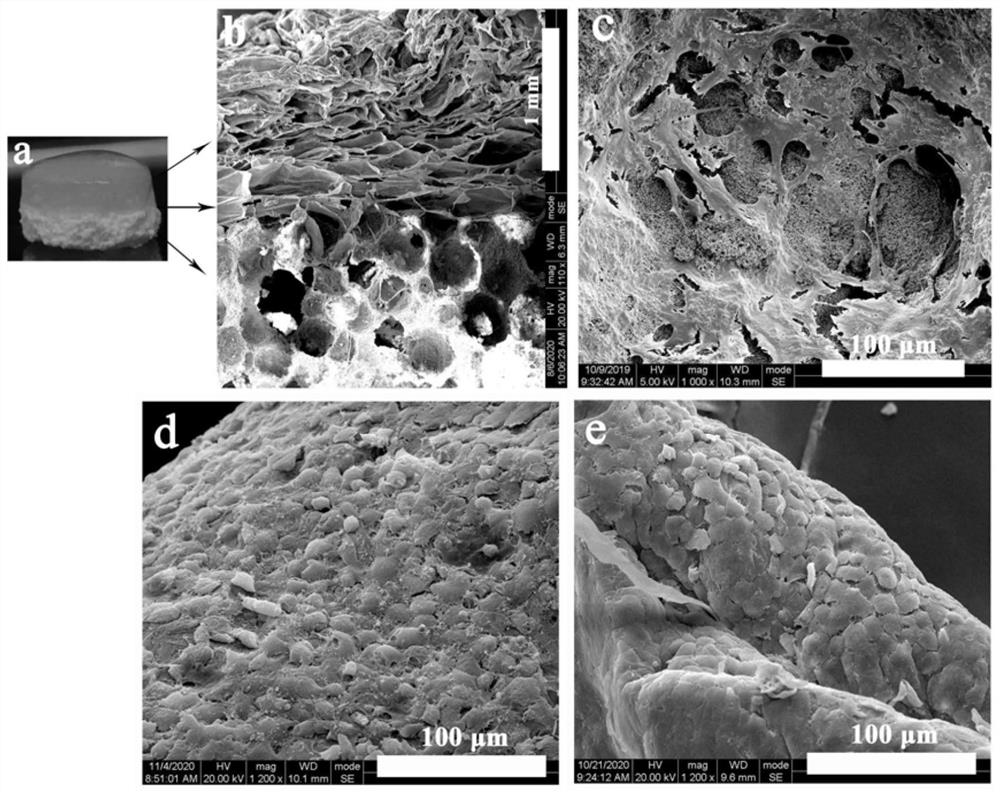

[0046] In this example, the scaffold material for osteochondral repair of the mandibular condyle was prepared, and the steps were as follows:

[0047] (1) Place the formed porous biphasic calcium phosphate ceramics (porous BCP ceramics) in a cylindrical mold with an inner diameter of 8 mm and a height of 3 mm. The porous BCP ceramics are composed of hydroxyapatite and β-tricalcium phosphate, and the hydroxyl The mass ratio of apatite to β-tricalcium phosphate is 3:7, and the porosity is about 75%. The formed porous BCP ceramics is a cylindrical block with a diameter of 8mm and a height of 1.5mm. The formed porous BCP ceramics adopts the same mold The coaxial way is placed on the closed end of the cylindrical mold.

[0048] (2) Obtain primary cultured bone marrow mesenchymal stem cells and chondrocytes: select 5-day-old infant rabbits, inject pentobarbital sodium to kill them, and extract bone marrow mesenchymal stem cells from bilateral femoral bone marrow cavities by centrifu...

Embodiment 3

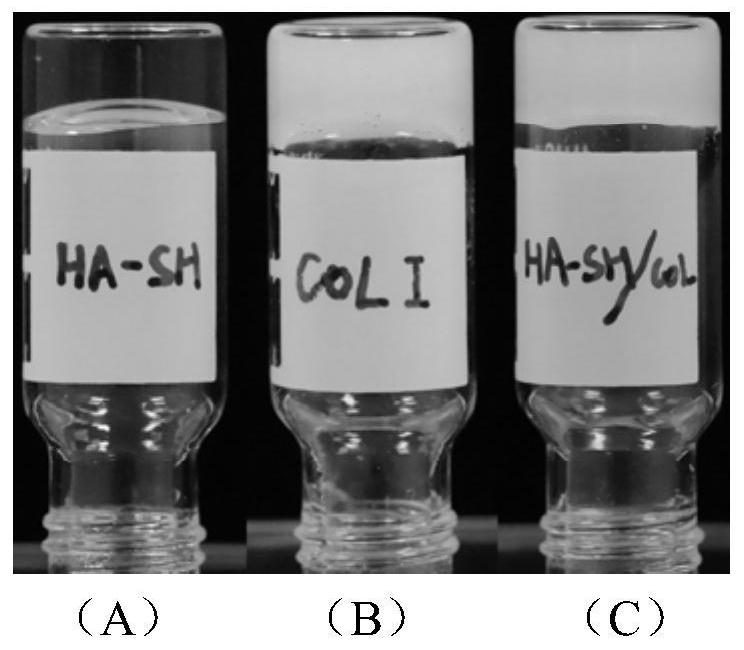

[0064] In this example, the physical and chemical properties of the composite hydrogel (HA-SH / Col I) of cross-linked mercapto-hyaluronic acid and type I collagen (HA-SH / Col I) were tested. as a control for comparison.

[0065] Dissolve the HA-SH prepared in Example 1 with α-MEM medium to obtain a concentration of HA-SH solution of 25 mg / mL; dissolve Col I with 0.25 mol / L acetic acid solution in an ice bath to obtain a concentration of 25 mg / mL Col I solution. Draw the HA-SH solution and Col I solution with a syringe respectively, and mix the HA-SH solution and Col I solution according to the volume ratio of 3:7 according to the group, adjust the pH to 7.4 with NaOH solution, and let it stand for a while at 37°C. Composite hydrogel HA-SH / Col I can be formed. Dissolve the HA-SH prepared in Example 1 with α-MEM medium to obtain a HA-SH solution with a concentration of 25 mg / mL, adjust the pH to 7.4 with NaOH solution, and stand at 37°C for a period of time to form HA-SH water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com