Flaw detection device for steel strand production

A flaw detection and steel strand technology, which is applied in the field of flaw detection and detection devices for steel strand production, can solve the problems of increased damage to the steel wire, vibration of the steel wire, affecting the detection accuracy of the device, etc., and achieves stable movement and good detection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

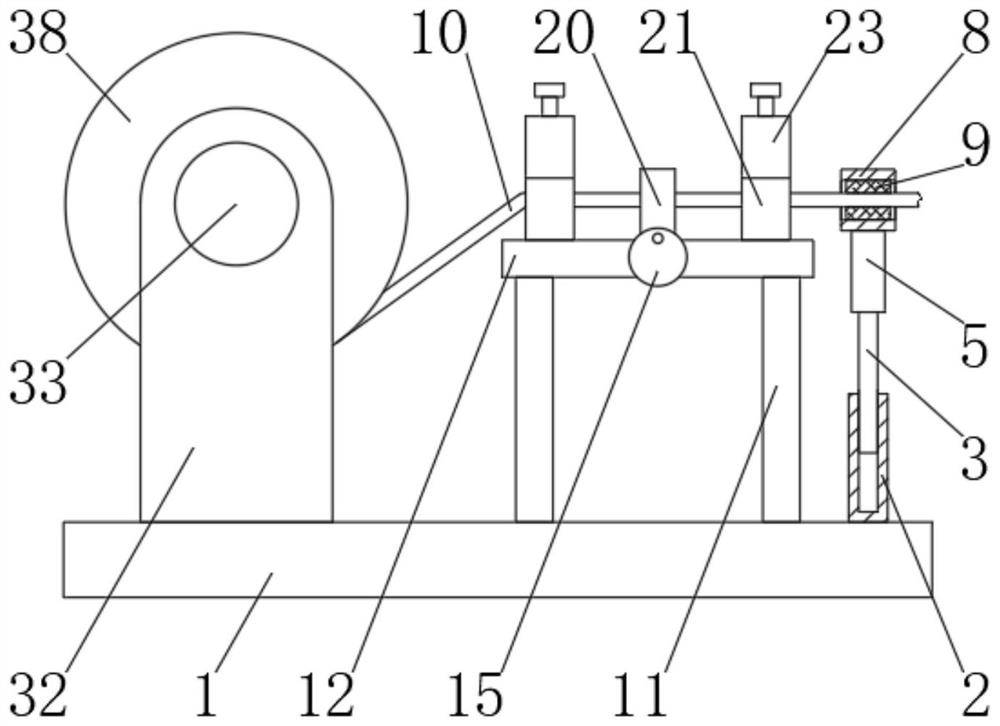

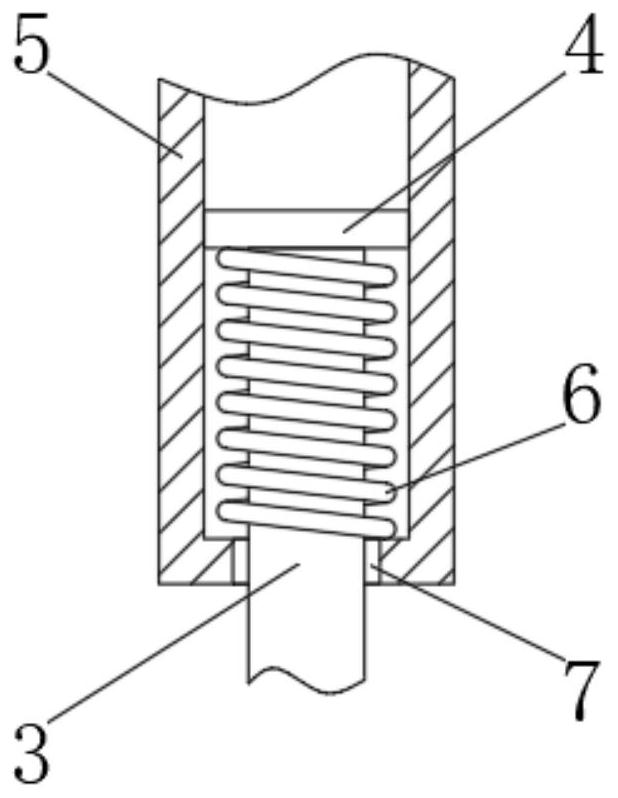

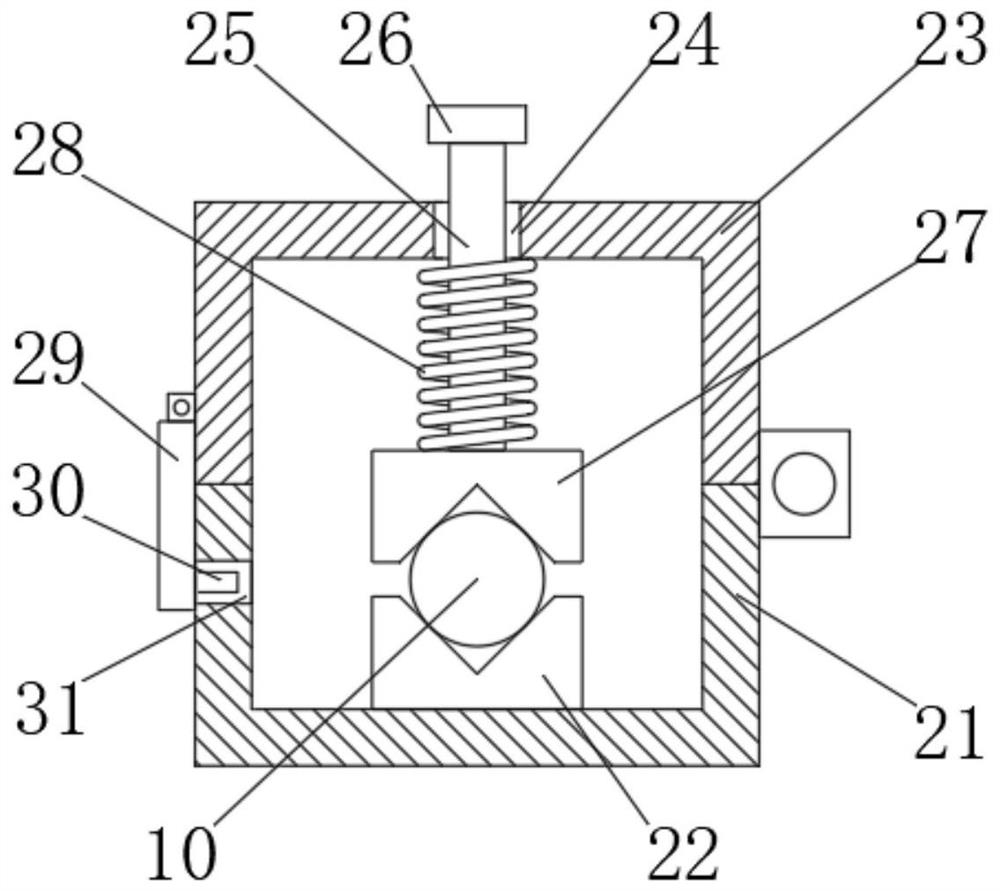

[0028] see Figure 1-6 , a flaw detection device for steel strand production, comprising a base plate 1, the upper end of the base plate 1 is welded with a sleeve 2, the sleeve 2 is threaded to a threaded rod 3, the upper end of the threaded rod 3 is welded with a baffle plate 4, the baffle plate The outside of 4 is slidingly sleeved with a support tube 5, a spring 6 is arranged inside the support tube 5, a support sleeve 8 is welded on the upper end of the support tube 5, a sponge block 9 is arranged inside the support sleeve 8, and a steel wire is sleeved inside the support sleeve 8 10. The surface of the sponge block 9 is contacted with a steel wire 10, and the bottom plate 1 is welded with a leg 11, and the upper end of the leg 11 is welded with a support plate 12, and the support plate 12 is connected with a forward and reverse threaded screw 13 for rotation, and the forward and reverse The outside of the threaded screw 13 is threadedly connected with a slide block 17, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com