Layered stress calculation method of steel-cored aluminum stranded wire under thermo-mechanical coupling effect

A steel-cored aluminum stranded wire and thermal-mechanical coupling technology, which is applied in the field of overhead conductor design and calculation, can solve the problems of lack of research on the stress distribution of conductor layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

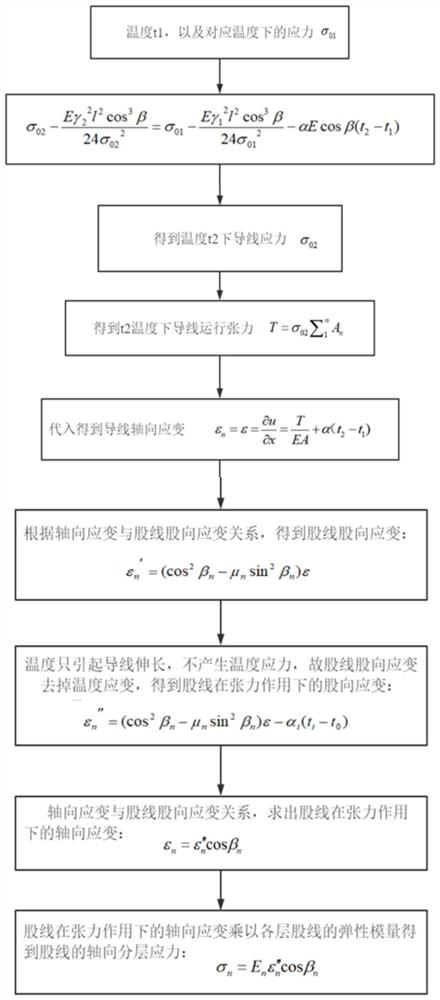

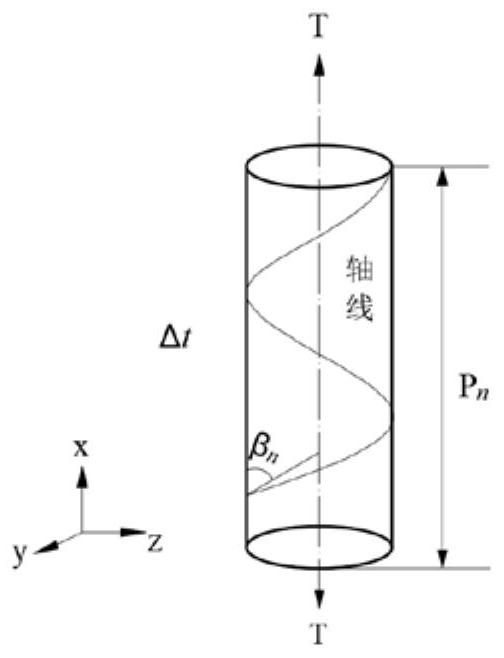

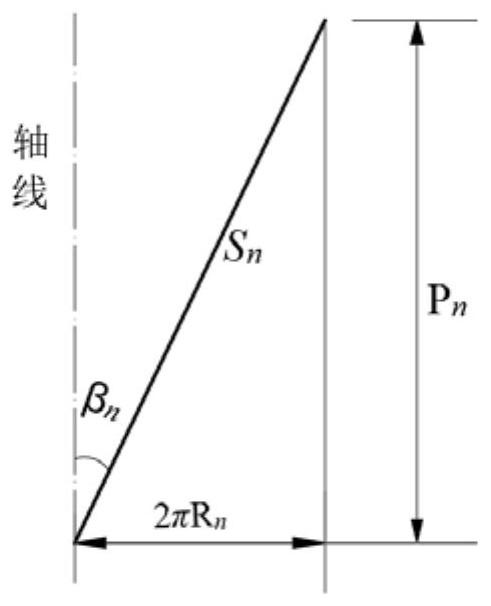

Method used

Image

Examples

Embodiment 1

[0126] Conductor geometric model and material parameters: The selected conductor model is: JL / G1A-400 / 35, the elastic modulus of the steel core is 190Gpa, and the Poisson’s ratio is 0.3; the elastic modulus of the aluminum strand is 55Gpa, and the Poisson’s ratio is 0.3; The geometric parameters of the wires are shown in Table 1.

[0127] Table 1 Geometric modeling parameters of ACSR JL / G1A-400 / 35

[0128]

[0129] Mesh division and boundary conditions: Complete the geometric model of the wire JL / G1A-400 / 35 in Solid Works, and import it into ANSYS for finite element analysis. Take the wire length as 100mm, and divide the grid as Figure 5 shown.

[0130] Boundary conditions: contact is set as a binding constraint; a fixed end is set on the x=0mm cross-section at the end of the constrained wire, and all degrees of freedom in the three directions of X, Y, and Z are constrained; only the symmetrical axial (x direction) tension of the wire is considered , ignoring the effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com