A kind of rail small flatbed car with multifunctional hand-holding, pushing and releasing the brake

A flatbed, multi-functional technology, applied to brakes with brake parts, operating mechanism of railway vehicle brakes, motor vehicles, etc., can solve problems such as difficult disassembly and installation, complex and bulky design structure, no brake structure, etc., to achieve Easy to disassemble and install, flexible installation, simple and fast fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

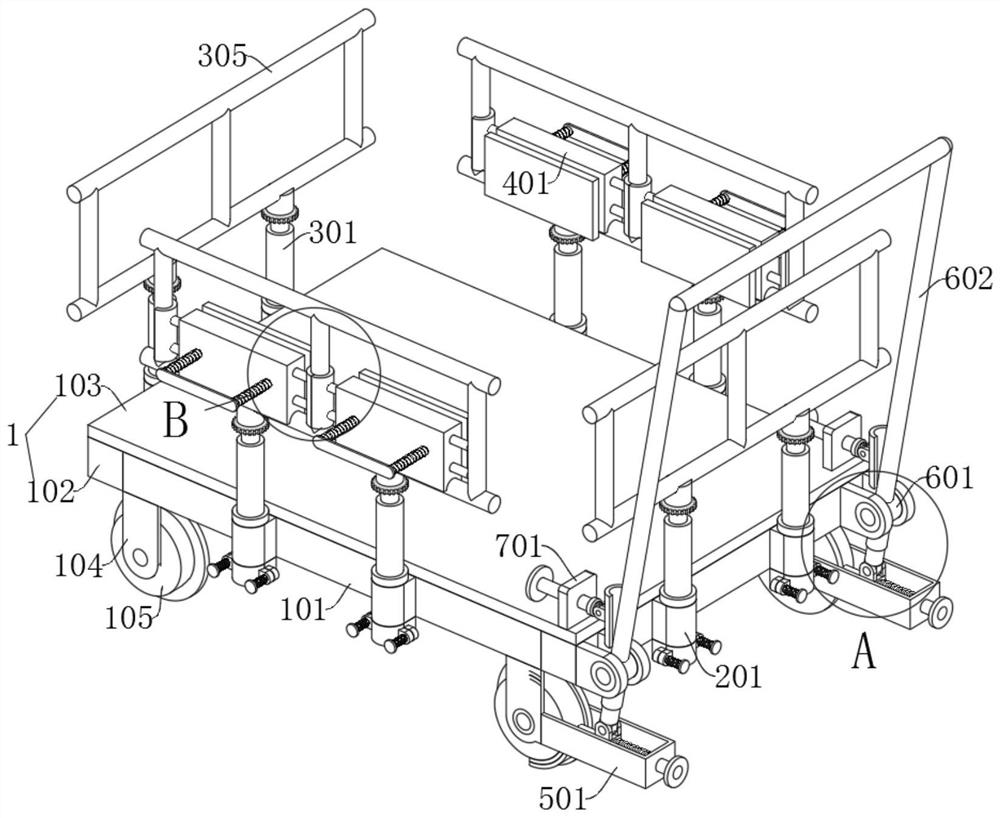

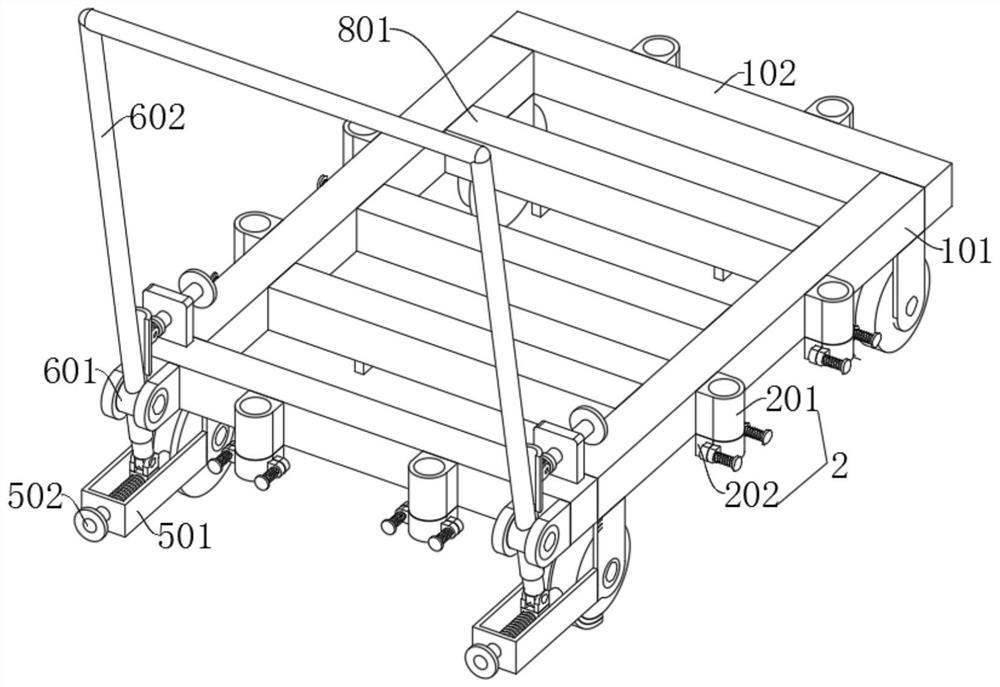

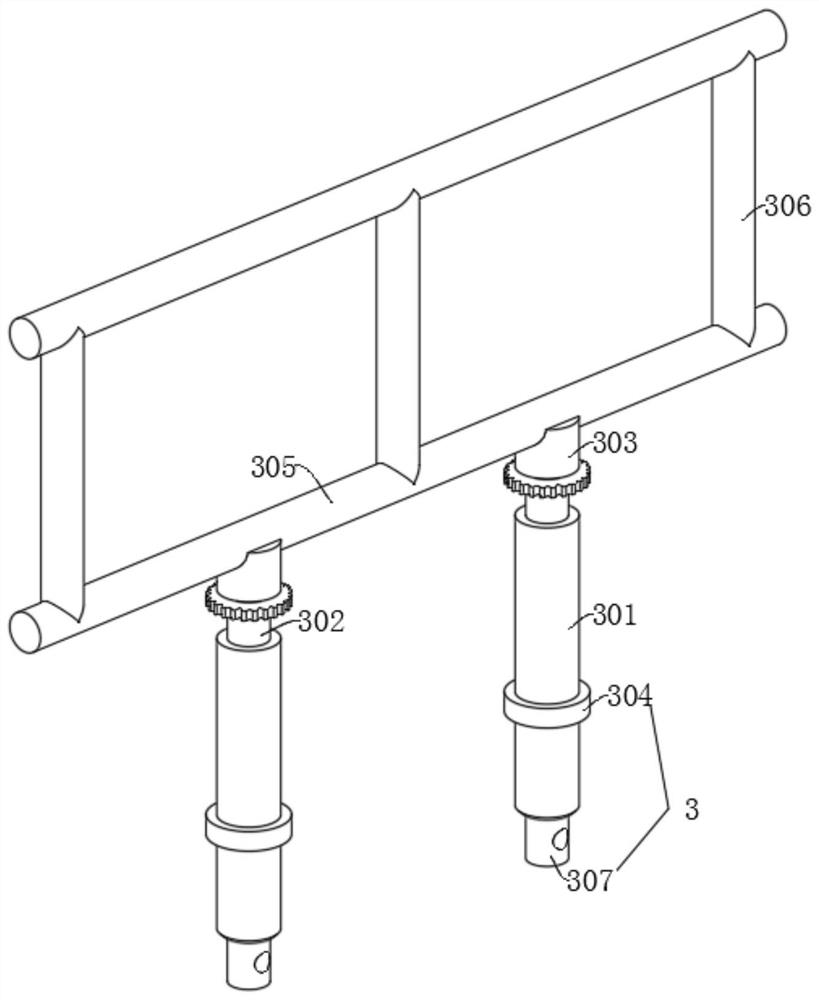

[0080] Example: please refer to Figure 1 to Figure 10 :

[0081] The present invention proposes a rail small flatbed vehicle with multi-function hand-holding and releasing hand braking, comprising: a flatbed car body 1, the flatbed car main body 1 includes: a support column 101, a connecting column 102, a support plate 103, a wheel frame 104 and a track wheel 105, The main body of the support column 101 is set to a square structure, and the number of the support columns 101 is set to two groups; the connection columns 102 are fixedly arranged between the two groups of support columns 101 by welding, and the number of the connection columns 102 is set to three groups; the support plates 103 are welded to It is fixedly arranged on the top of the support column 101 and the connecting column 102; the wheel frame 104 is fixedly arranged at the bottom of the support column 101, and the main body of the wheel frame 104 is set to a U-shaped structure, and the number of wheel frames 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com