Dynamic synchronous loading test device and method for deformed wing

A loading test device and wing technology, which is used in the testing of aircraft components, and the use of stable tension/pressure to test the strength of materials, etc. Synchronized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

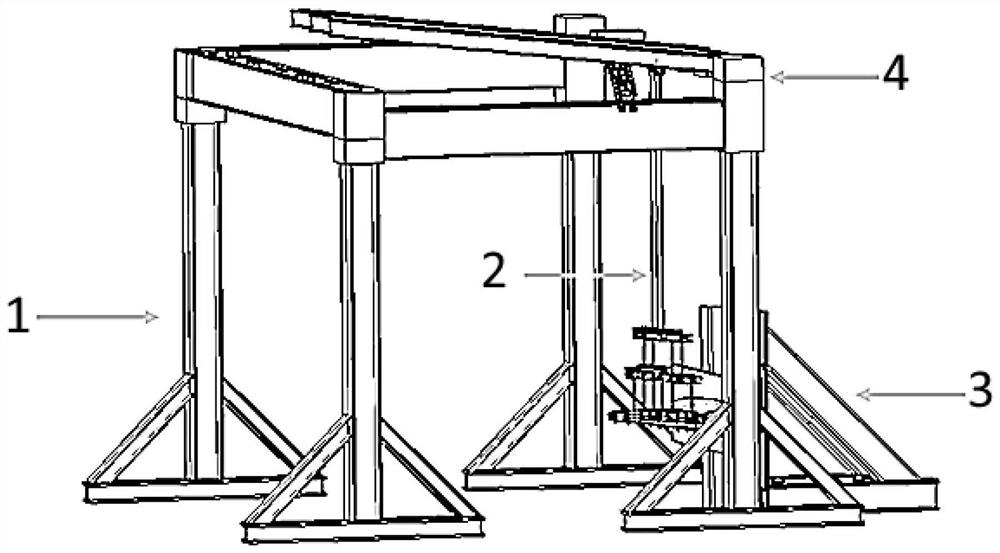

[0018] Such as figure 2 As shown, it is a dynamic synchronous loading test device for a deformed wing involved in this embodiment, including: a loading frame 1, a lever system 2, a loading base 3 and a loading motion system 4, wherein: the loading motion system 4 passes through the loading frame 1 Set on the loading base 3, the wing test piece 5 is suspended by the lever system 2 and loaded by the motion system 4.

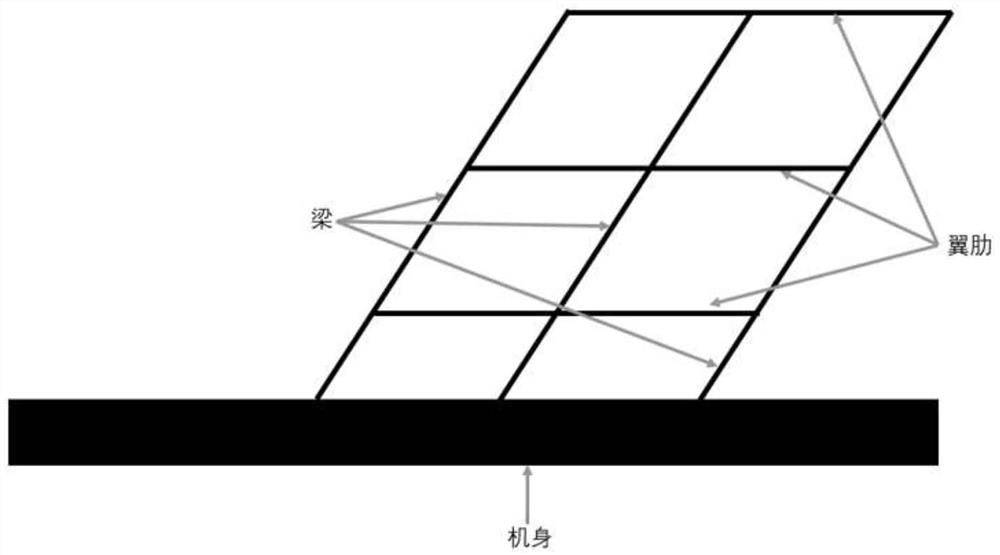

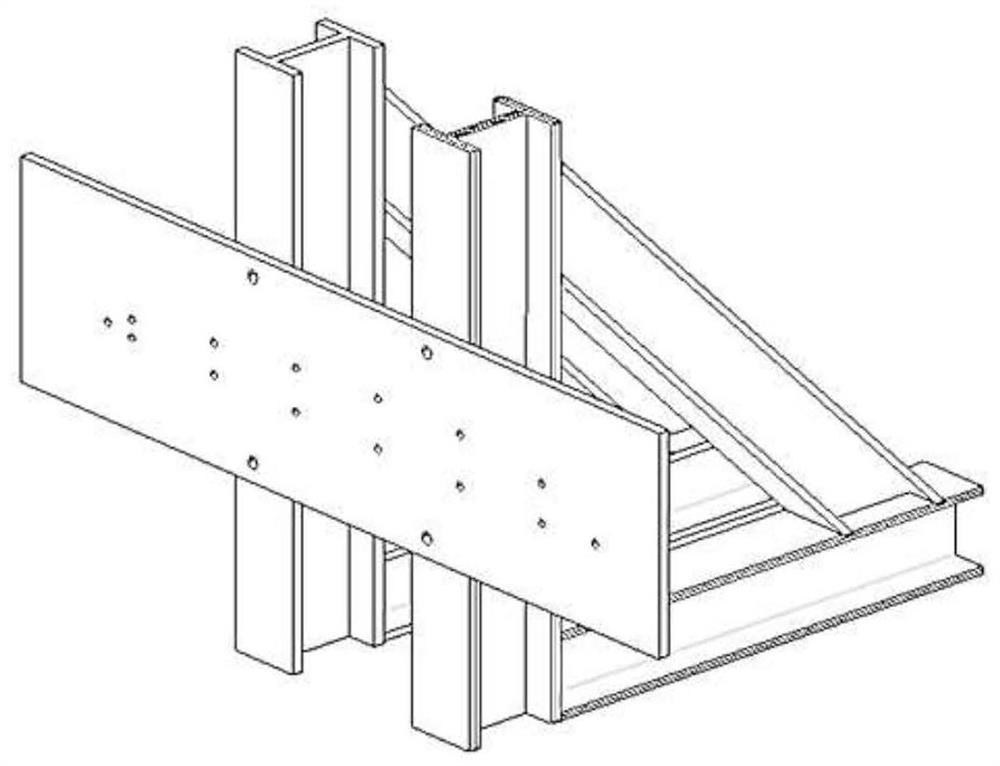

[0019] Such as image 3 As shown, the loading base 3 is fixed on the ground by bolts, and the wing test piece is installed through the mounting holes on the mounting plate, and a parallelogram is formed between the beam and the rib of the swept wing of the wing test piece.

[0020] Such as Figure 4 As shown, the lever system 2 specifically includes: several groups of lever branches 201, and each lever branch 201 is further connected to the surface of the wing test piece 5 through at least one layer of lever branches.

[0021] For the lever branch, after select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com