Multi-component composite rare earth tungsten alloy wire rod and its rolling process and electrode

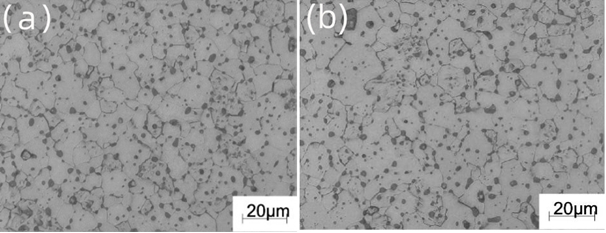

A multi-component composite and alloy wire technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of poor process controllability, less single deformation, uneven deformation, etc., and achieve high melting point and internal structure Uniform, uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

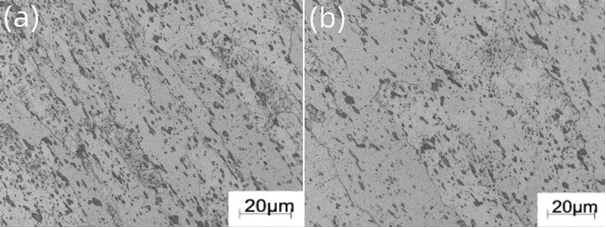

[0096]This embodiment provides a multi-element composite rare earth tungsten alloy wire rod. In the tungsten alloy rolling process, the tungsten alloy rod Φ15.5 mm is first put into a heating furnace to be heated to 1600 ° C, and then sent to a rolling mill for rolling; The total deformation from Φ15.5mm to Φ8.0mm is 74%, and it is divided into 8 compression pass diameters in order of 14.29-12.96-12.09-10.96-9.03-8.3-8.63-8.0, and the compression ratio of each pass is 15 %, 15%, 10%, 10%, 8%, 8%, 5%, 3%, each pass processing temperature 1550°C, 1530°C, 1500°C, 1480°C, 1460°C, 1440°C, 1400°C, 1380°C ℃, the overall processing speed is 10m / s. Annealing treatment is carried out after rolling, and the specific annealing temperature is: 1400° C.; the annealing time is 5 minutes.

Embodiment 2

[0098] This embodiment provides a multi-element composite rare earth tungsten alloy wire. The difference from Embodiment 1 is that it is divided into 4 rolling passes, and the diameter of each pass is 12.87-10.68-9.29-8.08, and the compression ratio of each pass is 17%, 17%, 13%, and 13%, respectively, and the processing temperature of each pass is 1550°C, 1530°C, 1500°C, and 1480°C. The other steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

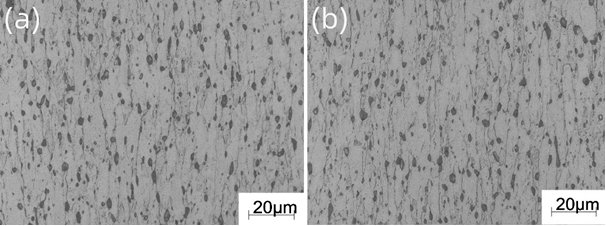

[0100] This embodiment provides a multi-element composite rare earth tungsten alloy wire. The difference from Embodiment 1 is that there are 10 compression pass diameters in sequence of 13.95-12.56-11.55-10.63-9.99-9.49-9.10-8.83, each pass The compression ratios are 10%, 10%, 8%, 8%, 6%, 5%, 4%, and 3%, respectively, and the processing temperature of each pass is 1550°C, 1530°C, 1500°C, 1480°C, 1460°C, 1440°C , 1400°C, 1380°C, 1360°C, 1340°C, and other steps are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com