Steel pipe horizontal supporting structure and construction method thereof

A technology of horizontal support and construction method, which is applied in basic structure engineering, excavation, construction, etc., and can solve problems such as inability to form a mesh structure, a large number of columns, and bending deformation of connecting beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

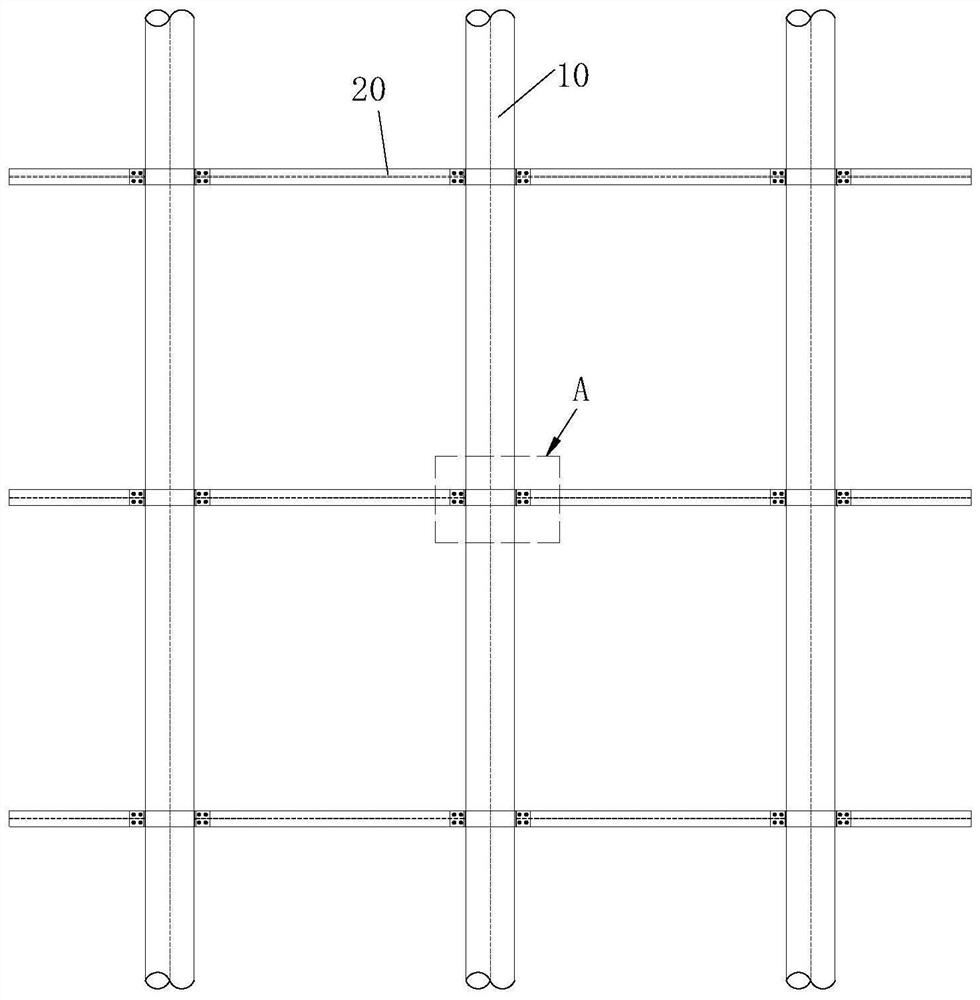

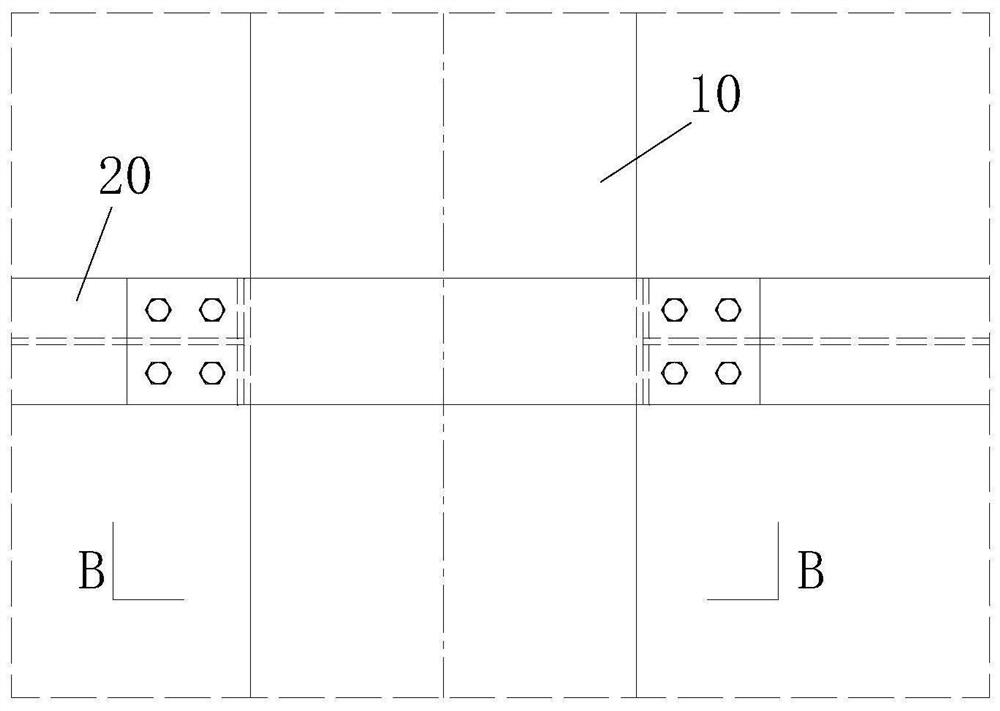

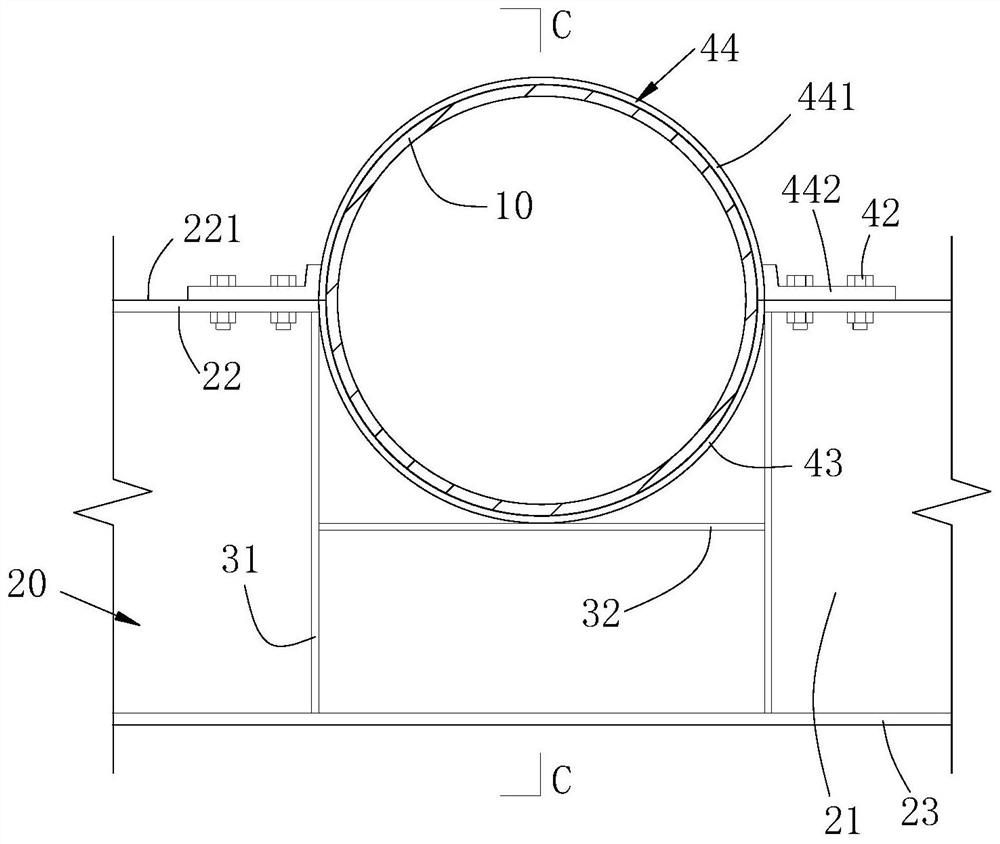

[0055] see Figure 1-Figure 6 , a steel pipe horizontal support structure, which includes a plurality of steel pipe main supports 10 and H-shaped steel connecting beams 20 supporting the plurality of steel pipe main supports 10, the plurality of steel pipe main supports 10 are arranged horizontally and parallel to each other.

[0056] The H-shaped steel connecting beam 20 extends in the horizontal direction, and its web 21 extends in the vertical direction. The upward flange of the H-shaped steel connecting beam is called the upper flange 22, and the downward facing flange of the H-shaped steel connecting beam is called The lower flange 23, on each H-shaped steel connecting beam 20, is provided with a notch 24 corresponding to each steel pipe main brace 10, the notch 24 is rectangular, and the notch 24 penetrates upwardly through the upper flange 22, And there is a distance from the lower flange 23 . It can be understood that, in other embodiments, the notch can also be in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com