Lifting aluminum water degassing refiner driven by gears

A technology of gear drive and refining machine, which is applied in the field of non-ferrous metal smelting. It can solve the problems of unstable force, aluminum liquid is easy to stick to the transmission chain, degassing rotor lifting and jamming, etc., and achieves the effect of smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

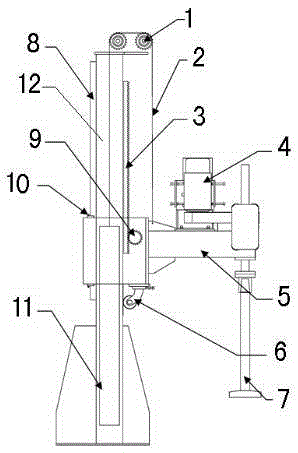

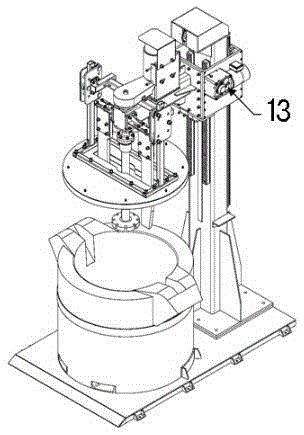

[0012] Depend on figure 1 , figure 2 As we know, the gear-driven lifting aluminum water degassing refiner consists of a transmission sprocket 1, a suspension chain 2, a double-row spur gear bar 3, a degassing motor 4, a degassing cantilever 5, a diagonal support roller 6, a degassing rotor 7, and a straight line Guide rail 8, spur gear 9, linear slider 10, counterweight 11, degassing column 12, lifting motor 13, degassing rotor 7 is installed on a degassing cantilever 5, driven by the degassing motor 4 through a pulley to rotate Two rows of driving spur gears 9 and two rows of linear guide rails 8 are fixed on the degassing column 12, which are distributed on the front and rear sides of the degassing column 12, and the linear slide block 10 matched with the linear guide rail 8 is fixed on the degassing cantilever 5, Make the degassing cantilever 5 slide up and down along the linear guide rail 8, the spur gear 9 driven by the lifting motor 13 is installed on the described deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com