Retard-bonded prestressed uplift pile connecting device and construction method thereof

A technology of slow-bonding prestressing and connecting devices, applied in protection devices, infrastructure engineering, sheet pile walls, etc., can solve the problems of water seepage at the basement floor, easy water seepage between the casing and the basement floor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

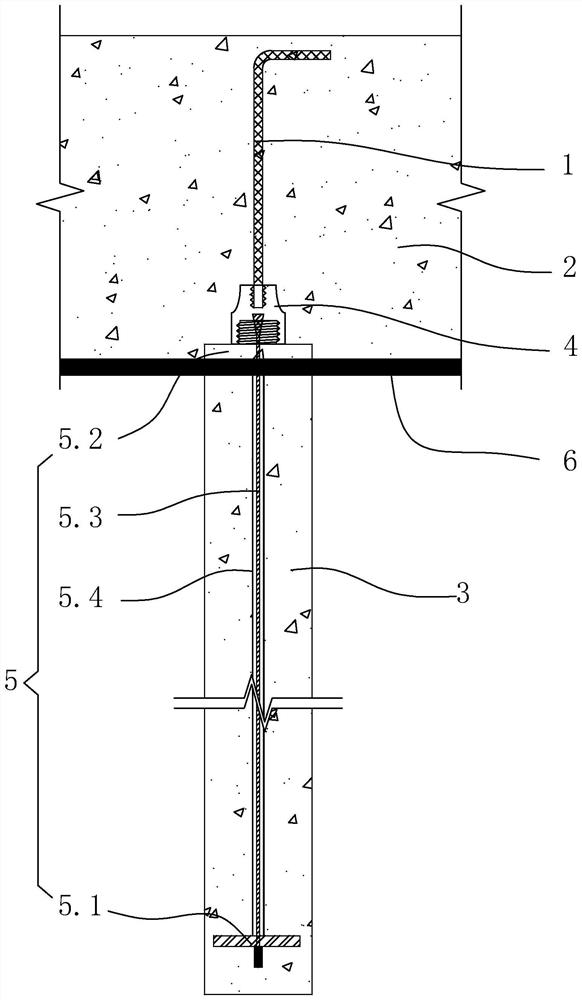

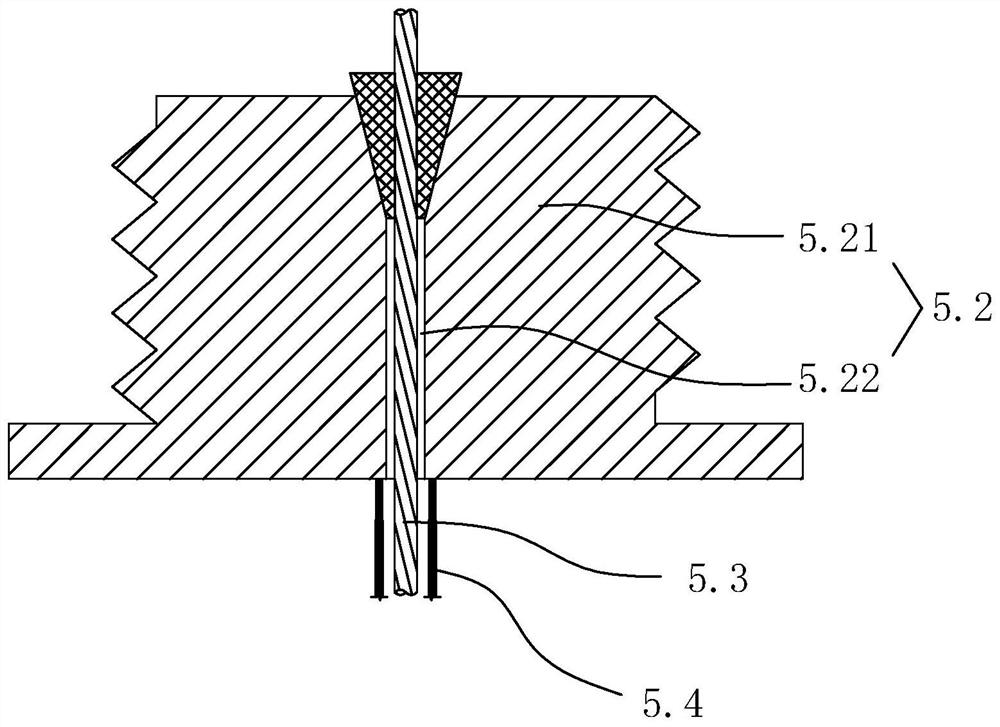

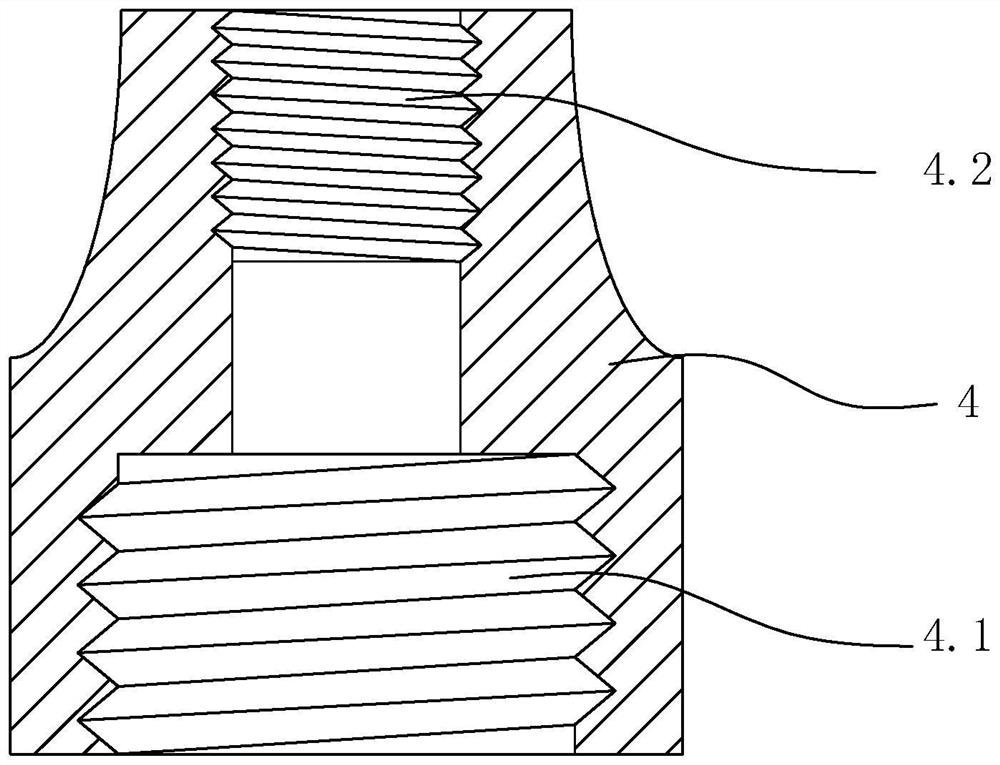

[0044] Specific embodiment one: as figure 1, figure 2 , image 3 As shown, a slow bonded prestressed uplift pile connection device, including:

[0045] An anchoring steel bar 1, the anchoring steel bar is anchored in the basement floor 2;

[0046] Pullout pile 3, the pullout pile is located below the basement floor;

[0047] The lower prestressed anchoring device 5, the lower prestressed anchoring device includes the lower anchorage 5.1 buried in the lower part of the uplift pile, the prestressed anchorage 5.2 fixed on the pile top of the uplift pile and the slow-bonding anchor buried in the uplift pile Bonded prestressed steel strands, slowly bonded prestressed steel strands include lower prestressed steel strands 5.3 connecting the lower anchorage and prestressed anchorages and sleeves 5.4 sleeved outside the lower prestressed steel strands. The gap between the pipe and the lower prestressed steel strand is filled with retarding adhesive;

[0048] An adapter 4, the ada...

specific Embodiment 2

[0056] Specific embodiment two, a construction method of slow bonded prestressed uplift pile connection device, the specific structure of slow bonded prestressed uplift pile connection device in the construction method of slow bonded prestressed uplift pile connection device Referring to specific embodiment one.

[0057] The construction method of the slow bonded prestressed uplift pile connection device includes the following steps in sequence:

[0058] First, drill holes at the bottom of the foundation pit to form uplift pile holes;

[0059] Second, the lower anchorage is connected to the lower end of the lower prestressed steel strand; then, the lower anchorage is lowered to the bottom of the uplift pile hole through the lower prestressed steel strand, and the casing is set on the lower prestressed steel strand outside the line;

[0060] Third, fill concrete in the holes of the uplift piles to form uplift piles;

[0061] Fourth, fix the prestressed anchor on the pile top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com