Roof photovoltaic support reinforcing construction method

A photovoltaic support and construction method technology, applied to the support structure of photovoltaic modules, photovoltaic modules, buildings, etc., can solve problems such as water seepage, and achieve the effects of avoiding water seepage, fixing and stabilizing, and increasing waterproof measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

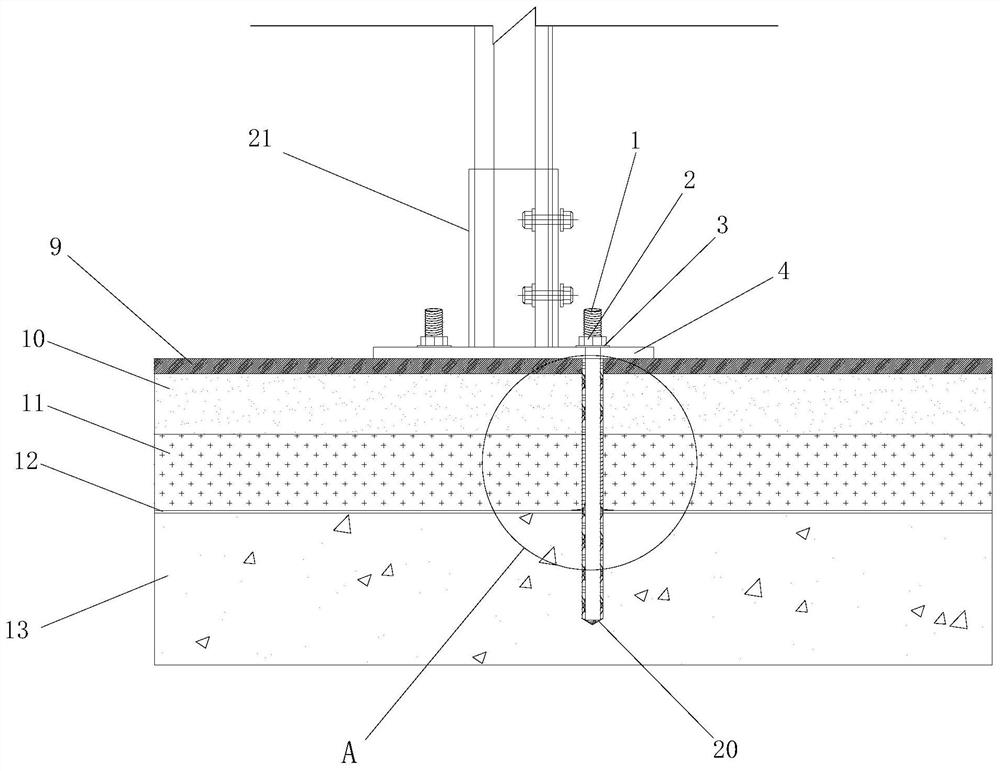

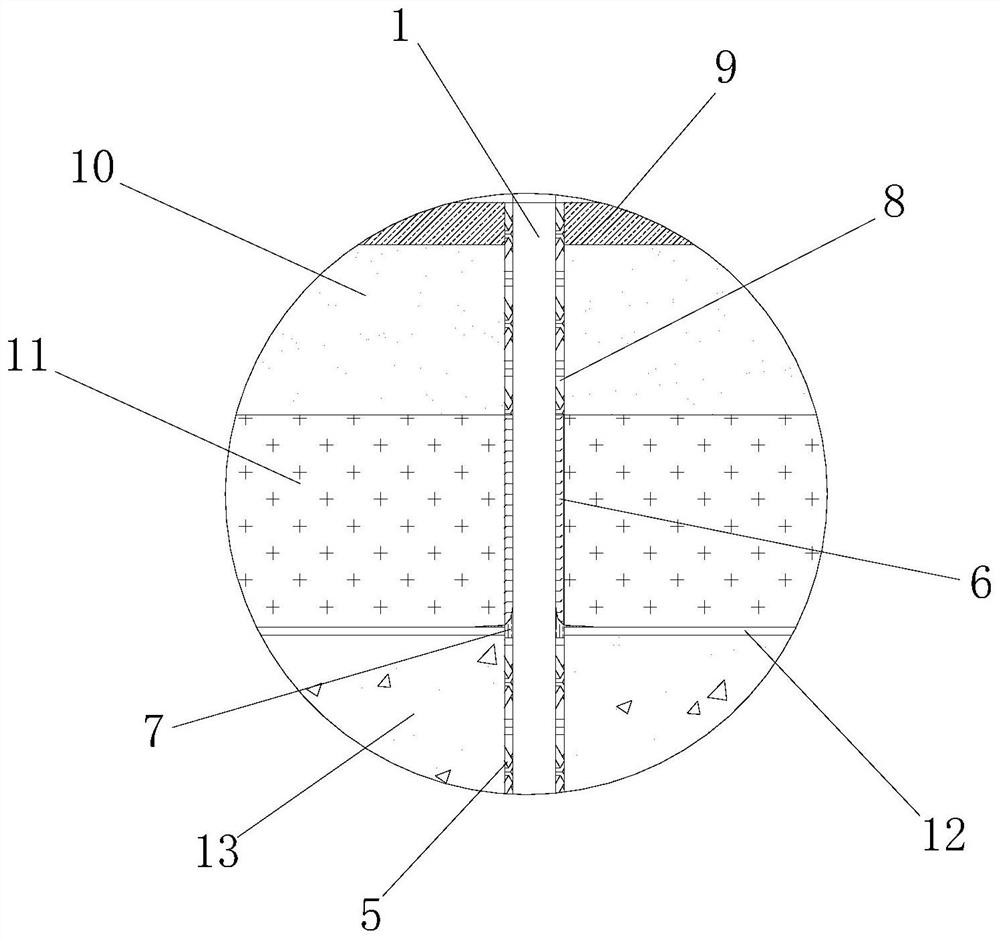

[0027] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments.

[0028] One embodiment of the present invention is a method for reinforcing a roof photovoltaic support, such as Figure 1-Figure 5 As shown, it includes: the following steps:

[0029] Step 1: According to the size of the design drawings, use a level to locate, and the ink fountain line records the fixed position of the roof photovoltaic support 21;

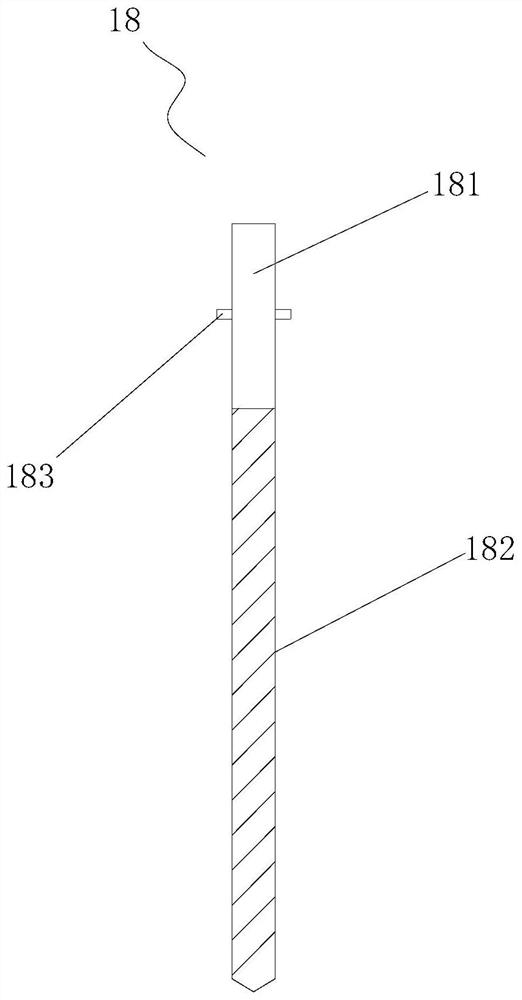

[0030] Step 2: According to the hole depth required by the design drawings, use the twist percussion drill bit 18 that can locate the drilling depth to be installed on the percussion drill, drill the anchor hole 20, check the hole depth and diameter of the anchor hole 20, and ensure that it is qualified;

[0031] Step 3: Use an air compressor type air cylinder to clean the dust in the anchoring hole 20, and ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com