Sampling device capable of avoiding sticking and blocking of sample in geological exploration and operation method

A geological exploration and sampling device technology, applied in the direction of sampling devices, etc., can solve the problems of sample sticking, blockage, difficulty in taking out samples, etc., and achieve the effect of increasing the tapping frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

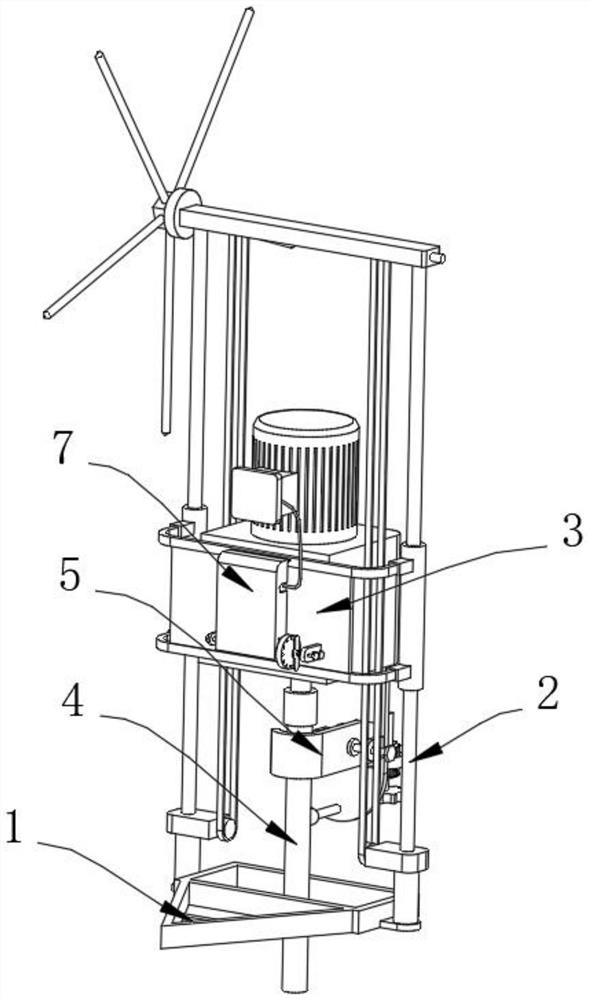

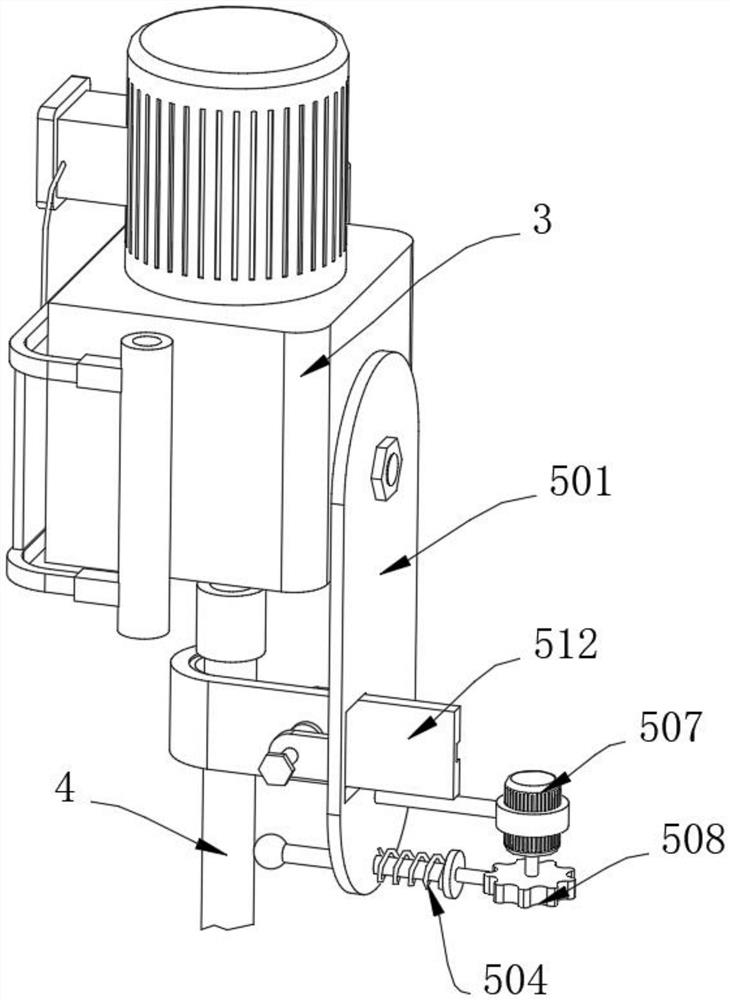

[0037] Example 1, such as Figure 1-9 As shown, the present invention provides a sampling device and an operating method that can avoid sample sticking and clogging in geological exploration, including a base 1, two screw mandrels 2 are installed on the upper end of the base 1, and the circular arc surfaces of the two screw mandrels 2 are threadedly connected with Drilling machine 3, control switch 6 is installed on the surface of drilling machine 3, sampling tube 4 is installed on the lower end of drilling machine 3, the surface of drilling machine 3 is provided with percussion structure 5, and the side of drilling machine 3 near control switch 6 is provided with protective structure 7.

[0038] Let's talk about the specific setting and effect of its knocking structure 5, protective structure 7 and method of operation in detail below.

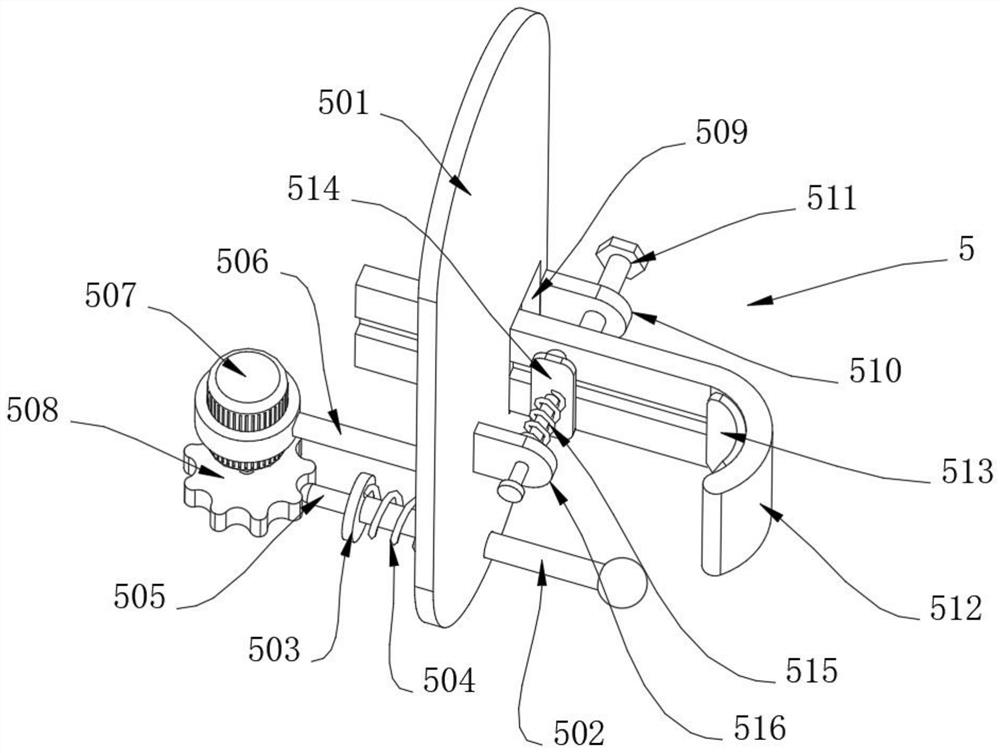

[0039] Such as image 3 and Figure 4 As shown, the knocking structure 5 includes a mounting plate 501, the mounting plate 501 is fixedly c...

Embodiment 2

[0050] Embodiment 2, on the basis of embodiment 1, this operation method step is:

[0051] S1. First check whether the equipment is normal, then place the base 1 at the location to be tested and fix it;

[0052] S2, start the drilling rig 3, so that the drilling rig 3 drives the sampling pipe 4 to perform drilling and sampling at the site to be measured;

[0053] S3, after the sampling is finished, use the screw mandrel 2 to move the drilling machine 3 upwards, and the sampling pipe 4 slides out from the soil to be tested;

[0054] S4. Hook the hook plate 512 on the sampling tube 4, and make the rubber pad 513 contact the surface of the sampling tube 4;

[0055] S5, start the motor 507, the motor 507 drives the adjustment wheel 508 to rotate, the adjustment wheel 508 continuously pushes the ejector rod 505, the ejector rod 505 drives the slide bar 502 to move, the slide bar 502 still knocks the sampling tube 4 continuously, and reaches the sample in the sampling tube 4 , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com