Root cause analysis method and device of operation and maintenance system, and equipment

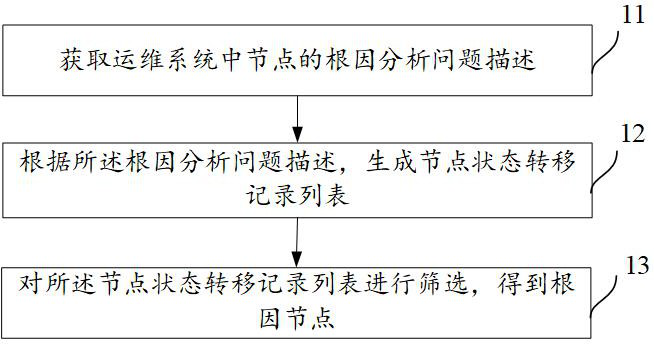

An operation and maintenance system and analysis method technology, applied in the direction of responding to errors, non-redundancy-based fault handling, instruments, etc., can solve problems such as inefficient fault location methods, untimely fault processing, etc., to reduce the average resolution time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

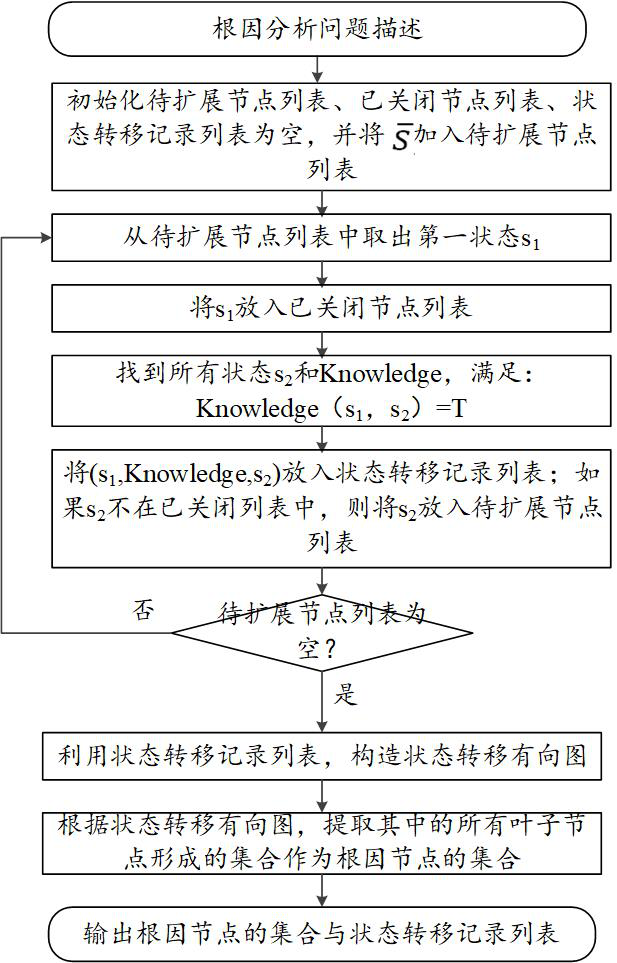

Embodiment Construction

[0045] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

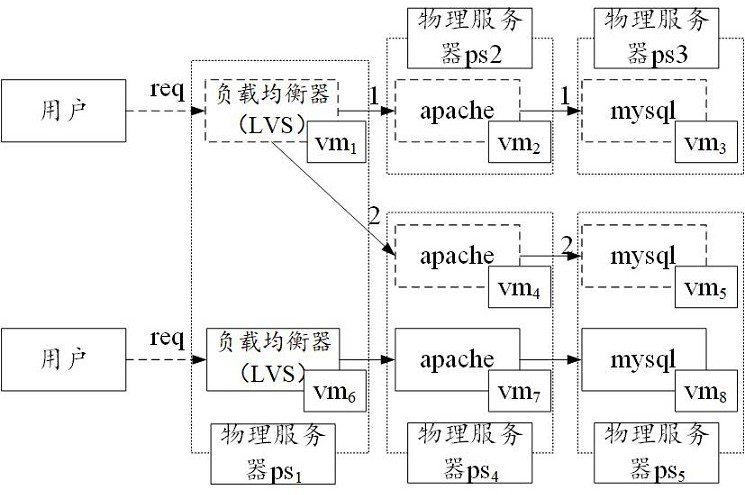

[0046] In the embodiments of the present invention, the operation and maintenance system refers to a general term for a collection of operation and maintenance object entities, such as a computer room of an Internet company in a certain place, a banking system, and the like.

[0047] Node: An entity module or an abstract module that implements a single function in the operation and maintenance system, such as microservices, servers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com