Wafer pre-alignment device and pre-alignment method

An alignment device and pre-alignment technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inability to identify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

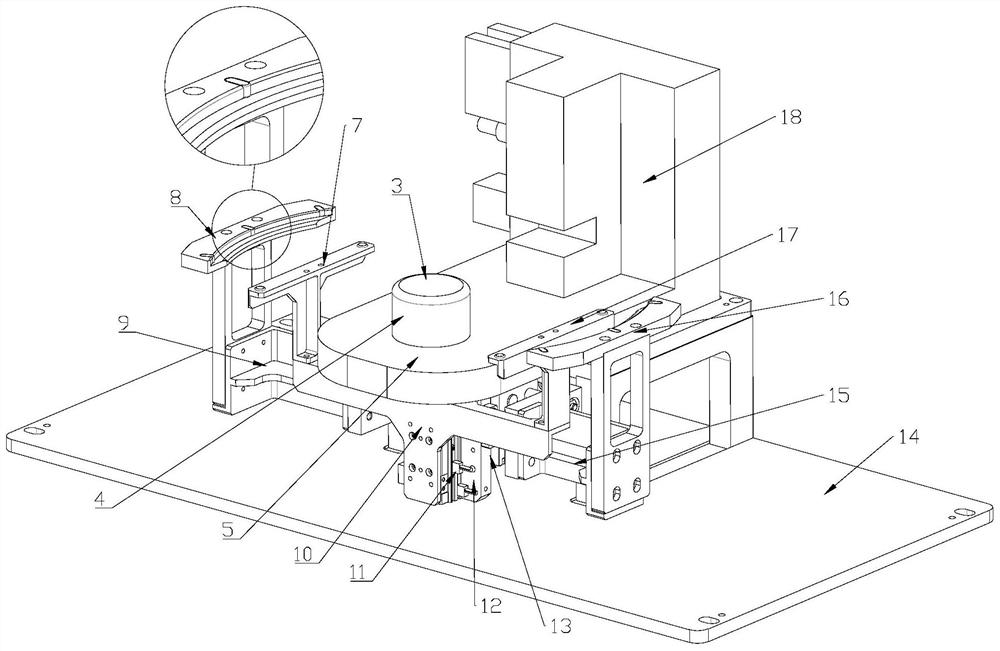

[0029] See attached Figure 1-2 As shown, a wafer 6 pre-alignment device of the present invention includes a bottom plate 14, above which is provided a carrying plate 5 parallel to it, and the carrying plate 5 is fixed on the bottom plate 14 through a fixing frame. The carrying plate 5 is provided with a rotating base 4, and the rotating base 4 is provided with a vacuum adsorption platform 3 which rotates synchronously with it. The vacuum adsorption platform 3 can absorb the wafer 6, and the rotating base 4 drives the vacuum adsorption platform 3 and the wafer 6 to synchronize. turn. One side of the rotating base 4 is provided with a visual inspection unit 18 for precise alignment of the wafer 6. The visual inspection unit 18 includes a stand fixed on one side of the rotating base 4, and a CCD vision sensor and a backlight are arranged on the stand. The vacuum adsorption platform 3 adsorbs and fixes the wafer 6, the rotating base 4 drives the wafer 6 on the vacuum adsorption ...

Embodiment 2

[0042] Refer to attached Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is only the difference in the jacking device. In this embodiment, the jacking device includes a jacking drive member 11 and a mounting seat 20. The mounting seat 20 is fixed on the bottom plate 14, and the jacking drive The output shaft of the part 11 is fixedly connected with the centering drive part, and the jacking drive part 11 drives the centering device to go up and down. The lifting driver 11 directly drives the centering device up and down, and the wafer 6 is lifted up by the groove bottoms of the left centering baffle 8 and the right centering baffle 16 of the centering device, and then centered. Other structures are the same as in Example 1.

[0043] The jacking device of this embodiment directly lifts up the centering device, so that the left centering baffle 8 and the right centering baffle 16 of the centering device can lift the wafer 6 on the vacuum adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com