Motor capable of prolonging service life of oil-retaining bearing

A bearing life and bearing technology, which is applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of stuck friction loss, failure to reach oil storage, and failure to form oil storage chambers, etc., to increase the life of oil-containing bearings and reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

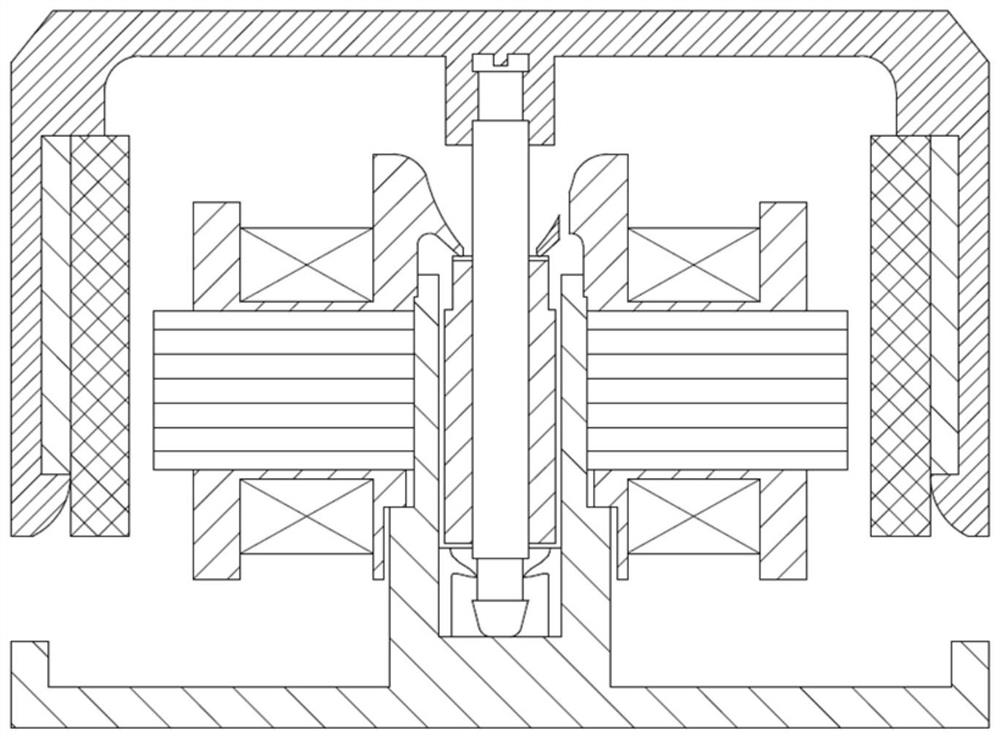

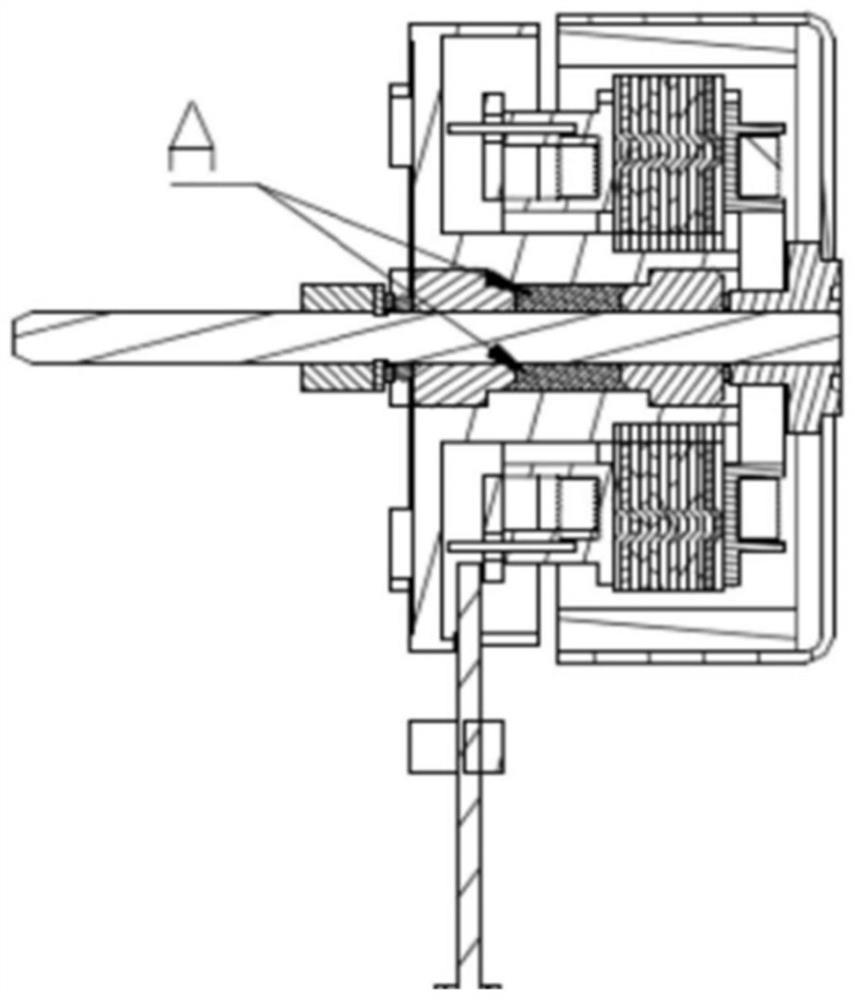

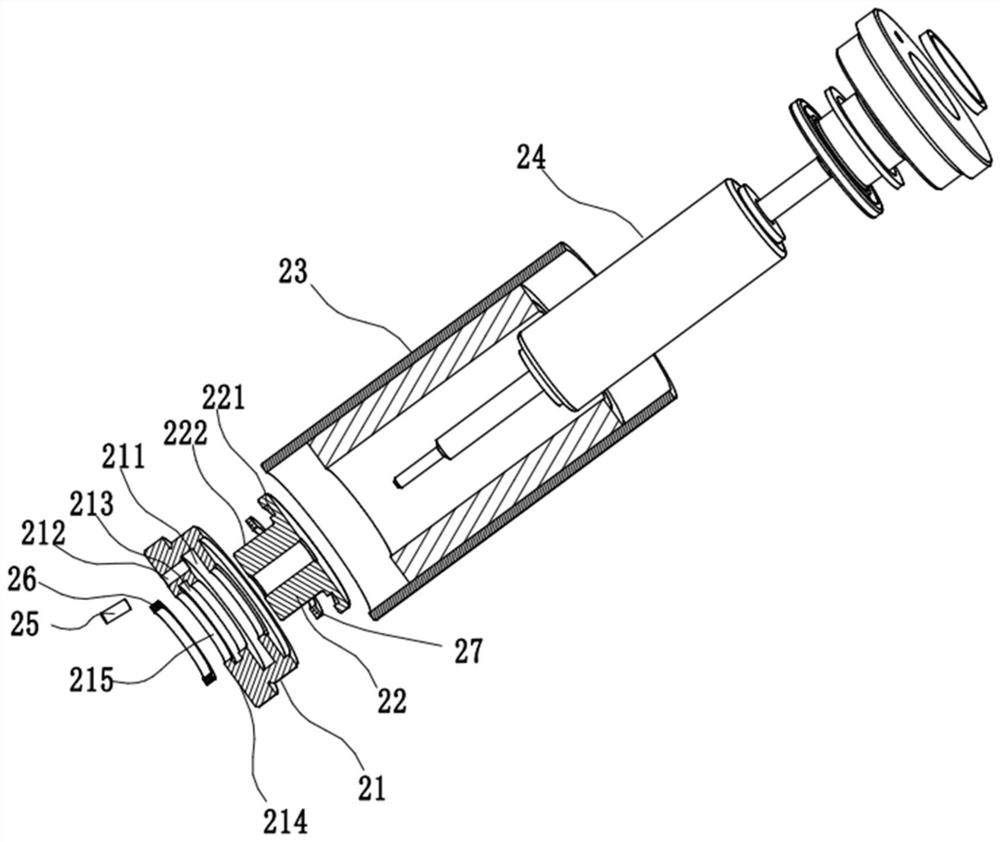

[0033] Such as Figure 3-4 As shown, a motor that can prolong the service life of the oil-impregnated bearing includes an end cover 21, an oil-impregnated bearing 22, a stator 23 and a rotor 24, and the rotor 24 is mounted on the oil-impregnated bearing 22 after being loaded into the stator 23, and the described The oil-impregnated bearing 22 is installed in the end cover 21, and the end cover 21 is provided with a bearing chamber 215 and an oil filling port 212. The bearing chamber 215 is provided with an oil storage tank 211, and the oil storage tank 211 is a circular ring with a rectangular cross section or other arbitrary cross section. Shaped rotary structure. One end of the oil storage tank 211 is inside the end cover 21, and the other end is in contact with the outer surface of the oil bearing 22. The oil filling port 212 is opened in the axial direction, one end is connected to the oil storage tank 211, and the other end is connected to the outer end surface 214 of the...

Embodiment 2

[0038] Such as Figure 5 and 6 As shown, the oil storage tank 211 is a first circular ring 211' with a required angle. Preferably, the angle of the first circular ring 211' is 180°. This design can leave the required space in the end cover, so that the motor that needs to go out has space to process the wire hole.

Embodiment 3

[0040] Such as Figure 7 and 8 As shown, the oil storage tank 211 is a plurality of second rings 211 ″ with a set angle, and the number of the oil filling ports 212 is the same as the number of the second rings 211 ″. Preferably, the multiple second rings 211" have the same angle and are evenly distributed. This design facilitates the addition of customer installation holes on the front cover. Correspondingly, the number of oil injection holes and rubber plugs must be consistent with the number of oil storage tanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com