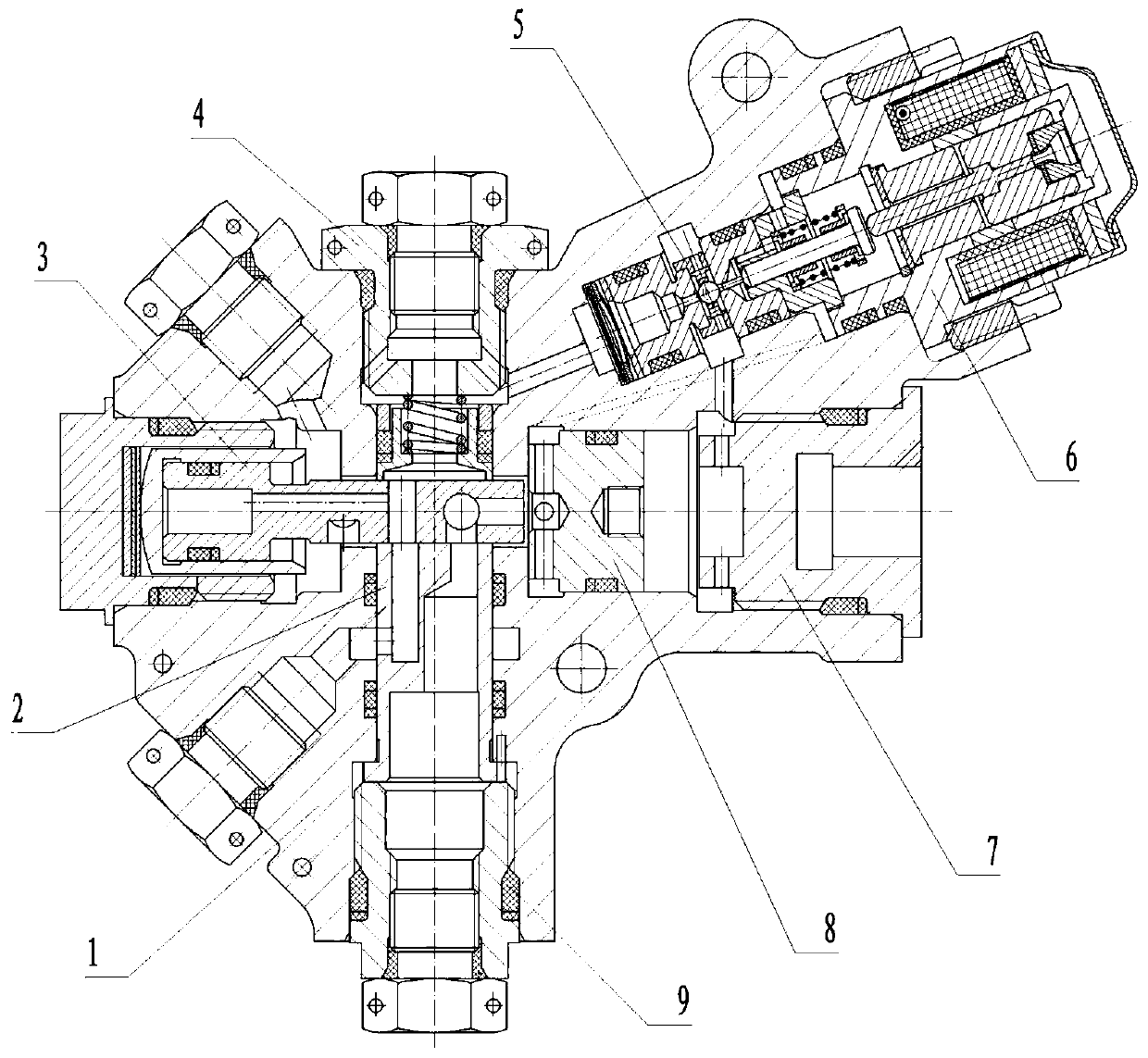

Pilot-operated type hydraulic electromagnetic valve for airplane braking

A hydraulic solenoid valve and pilot-operated technology, which is applied in the field of hydraulic solenoid valves, can solve the problems of not being able to meet the long-term working requirements of the hydraulic braking system of aviation aircraft, failing to meet the requirements of the hydraulic braking system of aviation aircraft, and not applicable to functions and performance. Achieve the effect of light weight, strong anti-pollution ability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

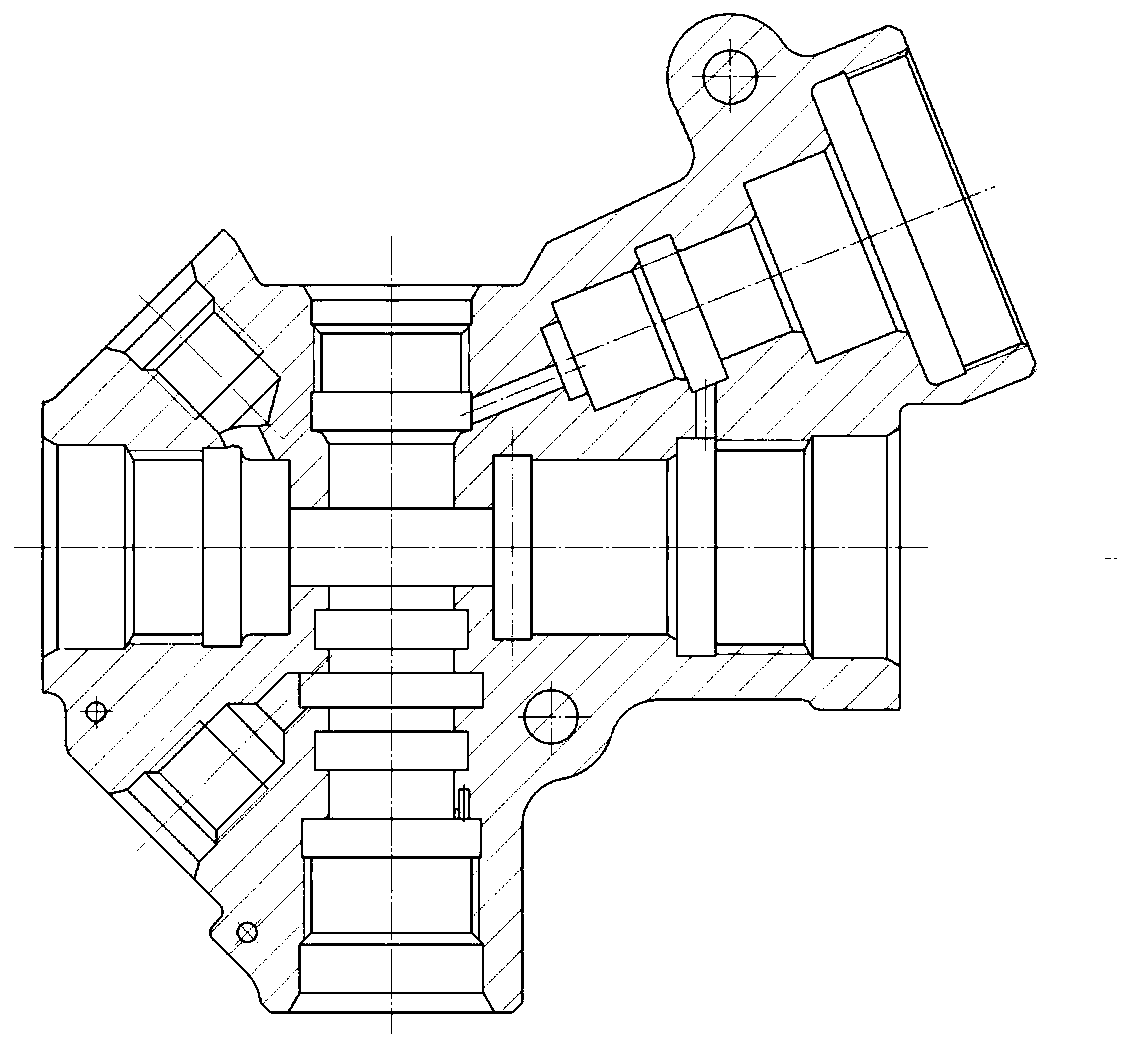

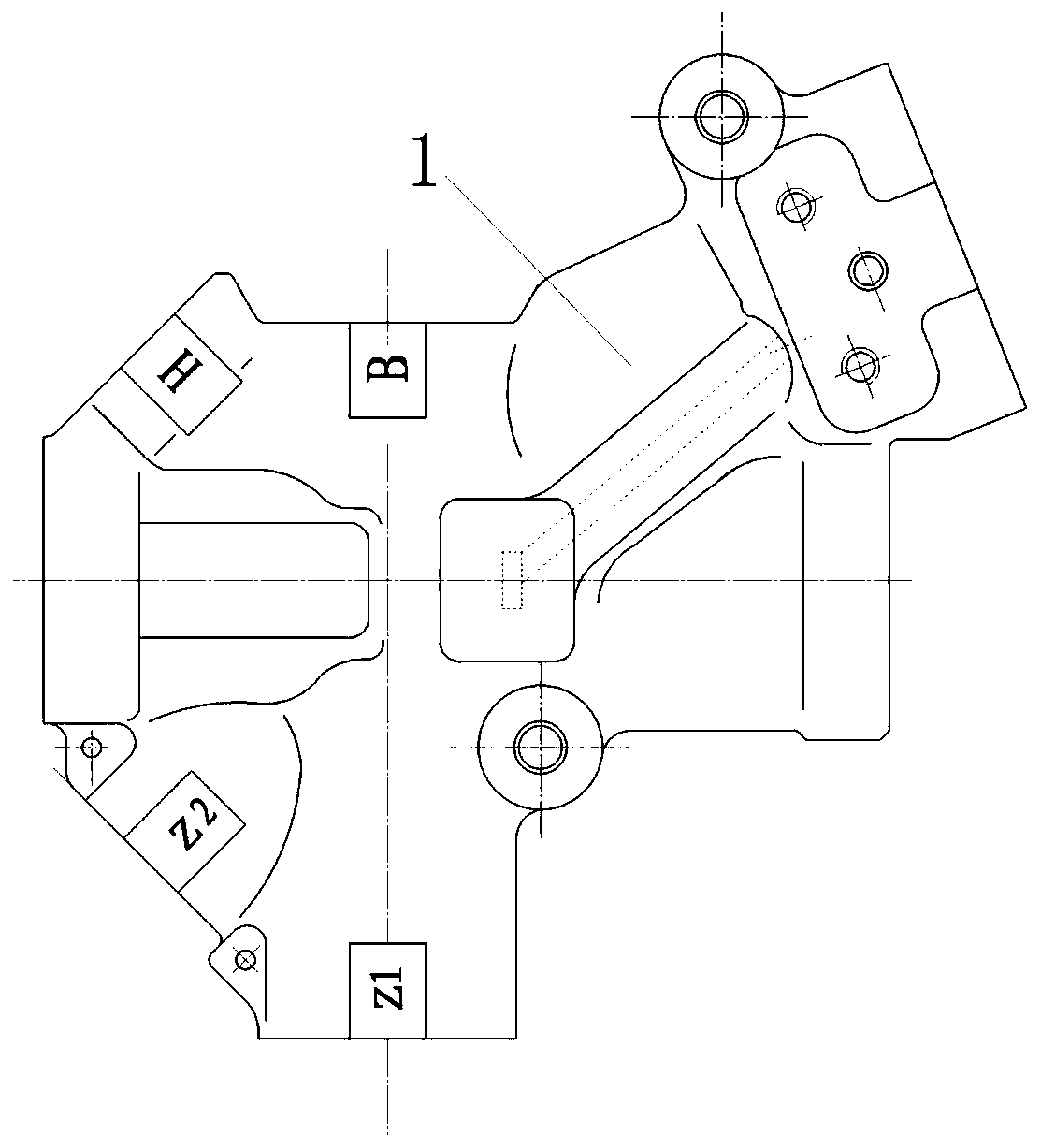

[0039] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0040] It has been explained in the background art above that the hydraulic solenoid valve is an important hydraulic control element in the aircraft braking system. It is suitable for hydraulic solenoid valves in aircraft hydraulic braking systems, and should generally have the following technical characteristics:

[0041] a), small size and light weight;

[0042] b), low power consumption; fast response, low noise;

[0043] c), strong anti-pollution ability;

[0044] d), Long-term type, high working reliability.

[0045] The influence of noise and anti-pollution ability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com