Tire cushion belt and producing method thereof

A manufacturing method and pad technology, applied to tire inflation valves, tire parts, tires, etc., can solve the problems of large thickness of the mouth hole of the pad, difficult production of the pad, easy crack damage, etc., and achieve good protection effect , reduce the labor intensity of production, and ensure the effect of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

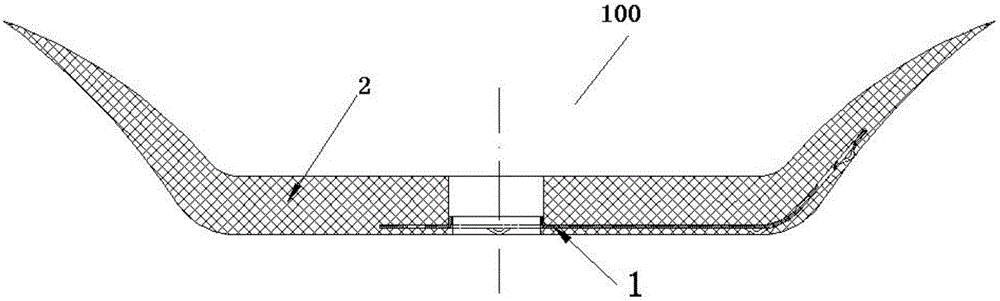

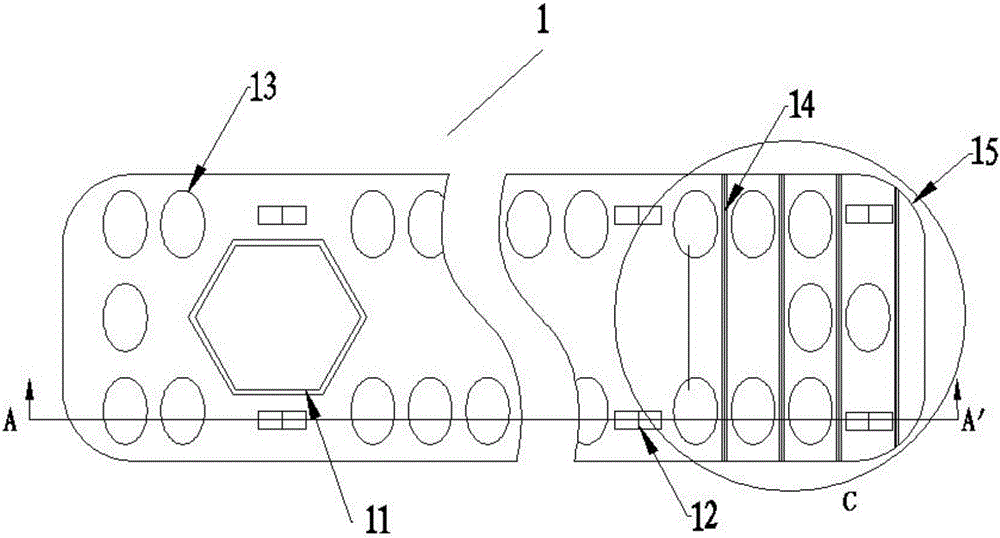

[0033] as attached Figure 1-Figure 9 As shown, a tire gasket 100 includes a metal gasket 1 and a film 2, the metal gasket 1 is provided with a gasket mouth hole 11, the metal gasket 1 is sheet-shaped, and one end thereof is upturned. The metal gasket 1 is embedded in the film 2 and wrapped by the film 2. The metal gasket 1 is provided with a number of adhesive holes 13 penetrating through its thickness. The metal gasket 1 is also provided with a plurality of V-shaped Shaped positioning V-groove 12, the lower part of the positioning V-groove 12 protrudes from the lower surface of the metal gasket 1, and the upturned end of the metal gasket 1 is provided with a plurality of bending grooves 14 running through its width direction. During the production of the tire cushion belt and tire assembly in this embodiment, the left and right directions of the valve must be installed according to the direction, otherwise the tire cushion belt will not have a protective effect.

[0034] Th...

Embodiment 2

[0045] Such as Figure 6-Figure 11 As shown, this embodiment is basically the same as Embodiment 1, except that both ends of the metal gasket 1 in this embodiment are upturned.

[0046] Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com