Foam filling device for toy production

A filling device and foam filling technology, used in toys, magnetic separation, solid separation, etc., can solve the problems of inability to remove iron particles, insufficient safety, and inability to screen foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

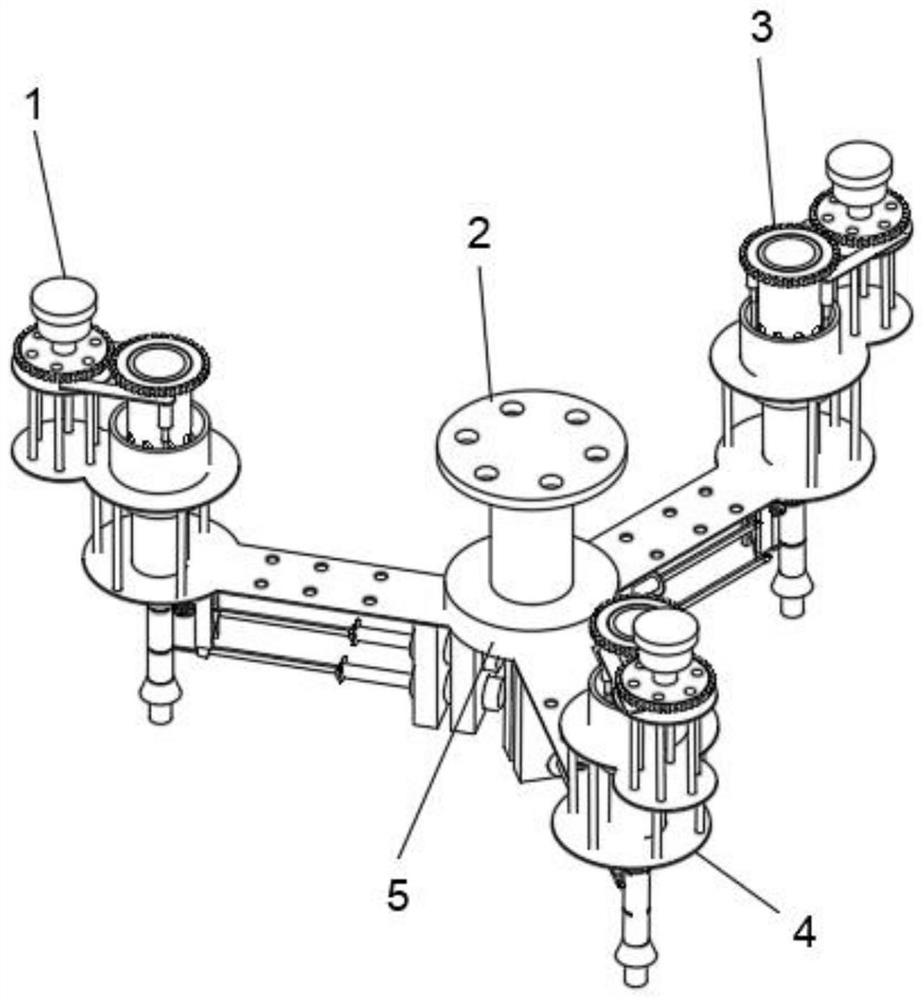

[0041] Such as Figure 1-2 , a foam filling device for producing toys, comprising a first filling device 1, a fixed mounting plate 2, a second filling device 3, a third filling device 4 and a fixed connection plate 5, the fixed connection plate 5 is rotatably connected to a fixed The bottom end of the mounting plate 2, the first filling device 1, the second filling device 3 and the third filling device 4 are fixedly connected to the fixed connection plate 5, and the first filling device 1, the second filling device 3 and the The structural specifications of the third filling device 4 are all the same, and the first filling device 1, the second filling device 3 and the third filling device 4 all include a screening and filtering device 6, a fixed mounting frame 7 and a separation and removal device 8, so The screening and filtering device 6 is connected to the bottom of the separation and removal device 8 , and the screening and filtration device 6 is fixedly connected to the s...

Embodiment 2

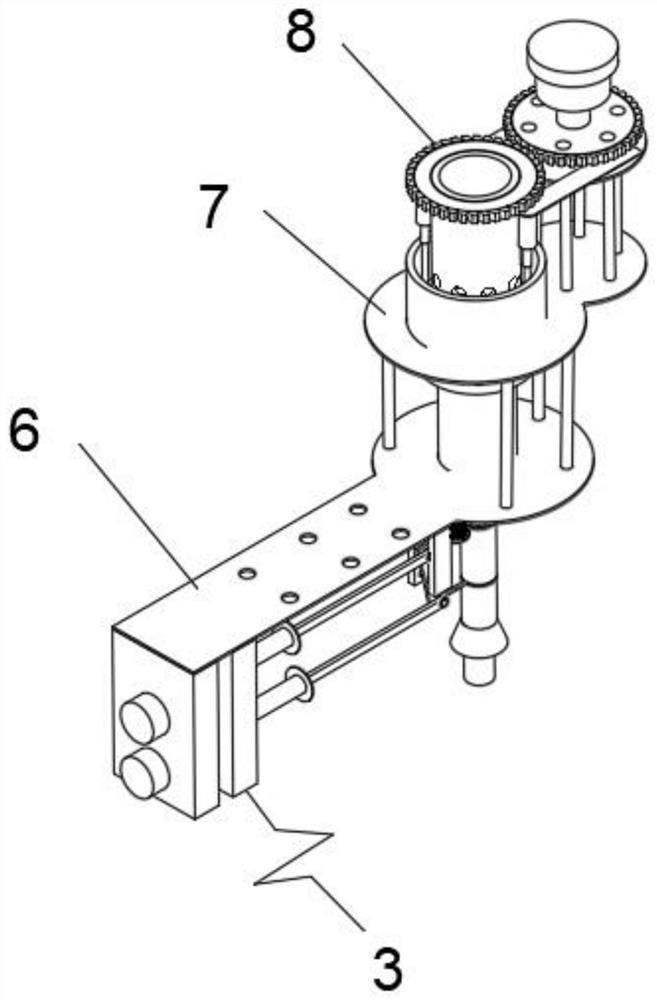

[0043] Such as image 3 , as a further optimization scheme of the above embodiment: a foam filling device for producing toys, comprising a first filling device 1, a fixed mounting plate 2, a second filling device 3, a third filling device 4 and a fixed connection plate 5, so The fixed connection plate 5 is rotatably connected to the bottom end of the fixed installation plate 2, the first filling device 1, the second filling device 3 and the third filling device 4 are fixedly connected to the fixed connection plate 5, and the first filling The structural specifications of the device 1, the second filling device 3 and the third filling device 4 are all the same, and the first filling device 1, the second filling device 3 and the third filling device 4 all include a screening and filtering device 6, a fixed mounting frame 7 and a separation and removal device 8, the screening and filtering device 6 is connected to the bottom of the separation and removal device 8, and the screeni...

Embodiment 3

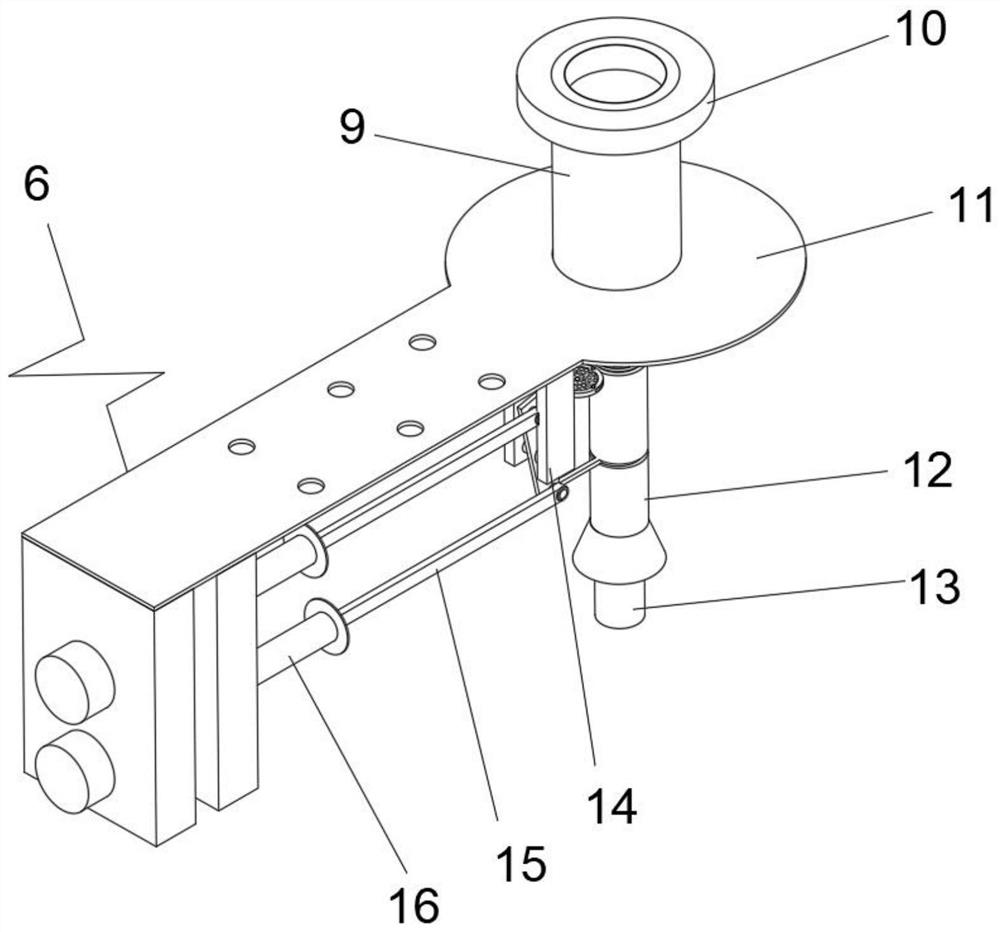

[0045] Such as Figure 4 , as a further optimization scheme of the above embodiment: a foam filling device for producing toys, comprising a first filling device 1, a fixed mounting plate 2, a second filling device 3, a third filling device 4 and a fixed connection plate 5, so The fixed connection plate 5 is rotatably connected to the bottom end of the fixed installation plate 2, the first filling device 1, the second filling device 3 and the third filling device 4 are fixedly connected to the fixed connection plate 5, and the first filling The structural specifications of the device 1, the second filling device 3 and the third filling device 4 are all the same, and the first filling device 1, the second filling device 3 and the third filling device 4 all include a screening and filtering device 6, a fixed mounting frame 7 and a separation and removal device 8, the screening and filtering device 6 is connected to the bottom of the separation and removal device 8, and the screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com