Modular ultra-low-nitrogen gas water heater

A gas-fired water heater, modular technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of water heaters not working, waste of resources, difficult to change the pressure supply power, etc., to ensure The effect of continuous water supply efficiency, prevention of waste of resources, and reduction of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

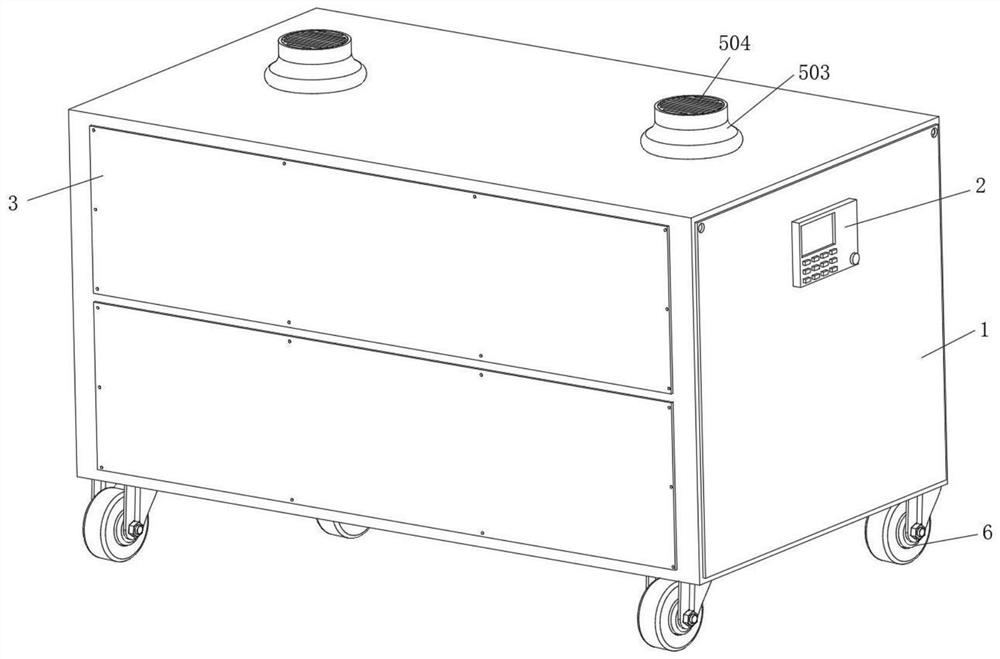

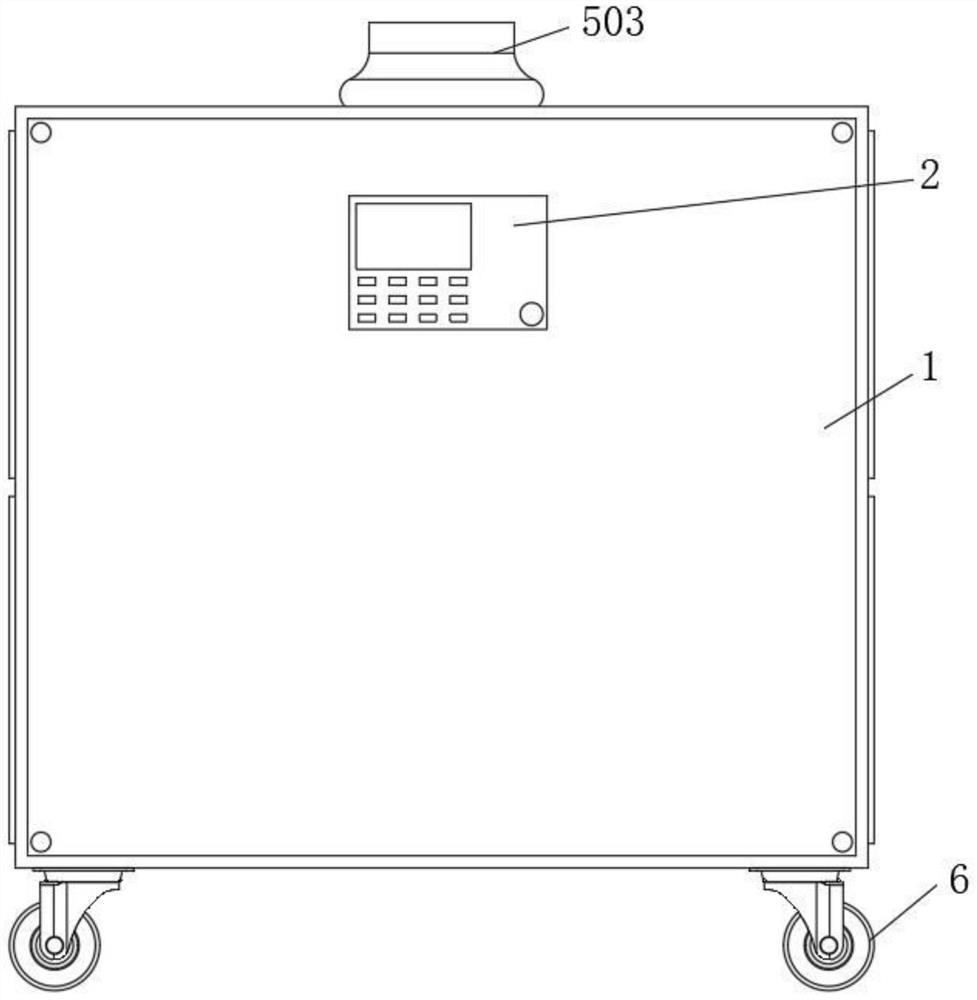

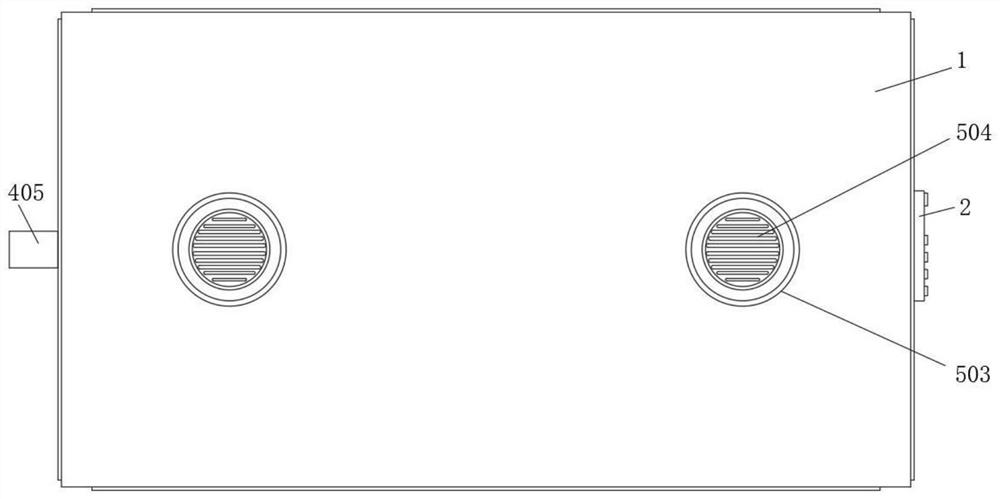

[0030] refer to Figure 1-6 , a modular ultra-low nitrogen gas-fired water heater, in order to prevent the waste of resources when the pressurized circulating water pump 401 is used, and improve the flexibility of maintenance, so as to improve the continuous water supply capacity of the water heater during maintenance, the settings here include Cabinet 1, the inner side of the cabinet 1 is fixed with a partition plate 101 that divides the cabinet 1 into upper and lower cavities, and the outer side of the cabinet 1 is fixedly connected with the control panel 2, and the side perpendicular to the control panel 2 is installed There are two sealing plates 3, the top side of the partition plate 101 and the inner bottom side of the box body 1 are fixedly connected with the support plate 4, and the top side of the support plate 4 is provided with a modular combination structure, one of the modular combination structures The side is connected with a smoke discharge structure 5;

[003...

Embodiment 2

[0034] Such as Figure 1-4As shown, this embodiment is basically the same as Embodiment 1. Preferably, in order to facilitate the safe discharge of flue gas after gas combustion, a flue gas discharge structure 5 is set here, including a main pipe 501, an auxiliary exhaust pipe 502, a purification head 503, and a baffle 504 and support block 505, the main pipe 501 is fixed inside the box body 1, and there is a smoke exhaust pipe 415 connected between it and each smoke connecting pipe 412, the auxiliary exhaust pipe 502 is connected with the main pipe 501, and the purification head 503 is fixed on The top of box body 1, and its bottom are communicated with main pipeline 501 and auxiliary row pipe 502 respectively, and support block 505 is fixed on the inner side of purification head 503, and baffle plate 504 is clamped on the top side of support block 505, and purification head 503 The inner side of the baffle is fixedly connected with an activated carbon mesh, and the activated...

Embodiment 3

[0037] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the pressurized circulating water pump 401 is provided with multiple powers instead of the same traditional power, and its bottom end is fixedly connected with the inner bottom end of the tank 1 .

[0038] In this embodiment, the pressurized circulating water pumps 401 with different powers are adjusted and used together, so that the pressurized circulating water pumps 401 can work in an optimal state, effectively prolonging the service life of the pressurized circulating water pumps 401 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap