Flux switching rotating electrical machine for traction for motor vehicle

A technology for rotating electrical machines, motor vehicles, applied in electromechanical devices, vehicle components, electric vehicles, etc., can solve problems such as anxiety or even unpleasantness, and achieve the effect of short response time and high torque level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

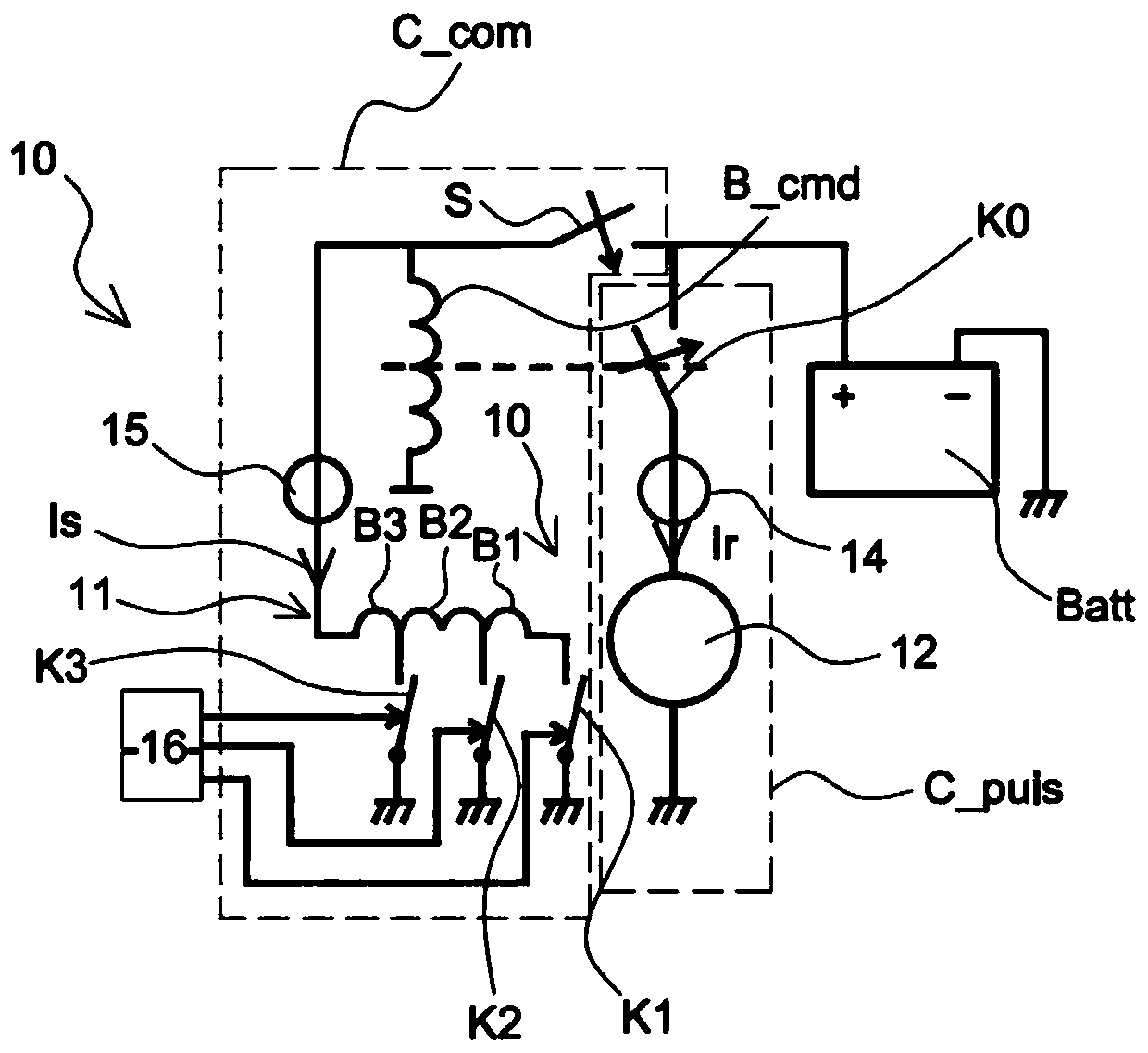

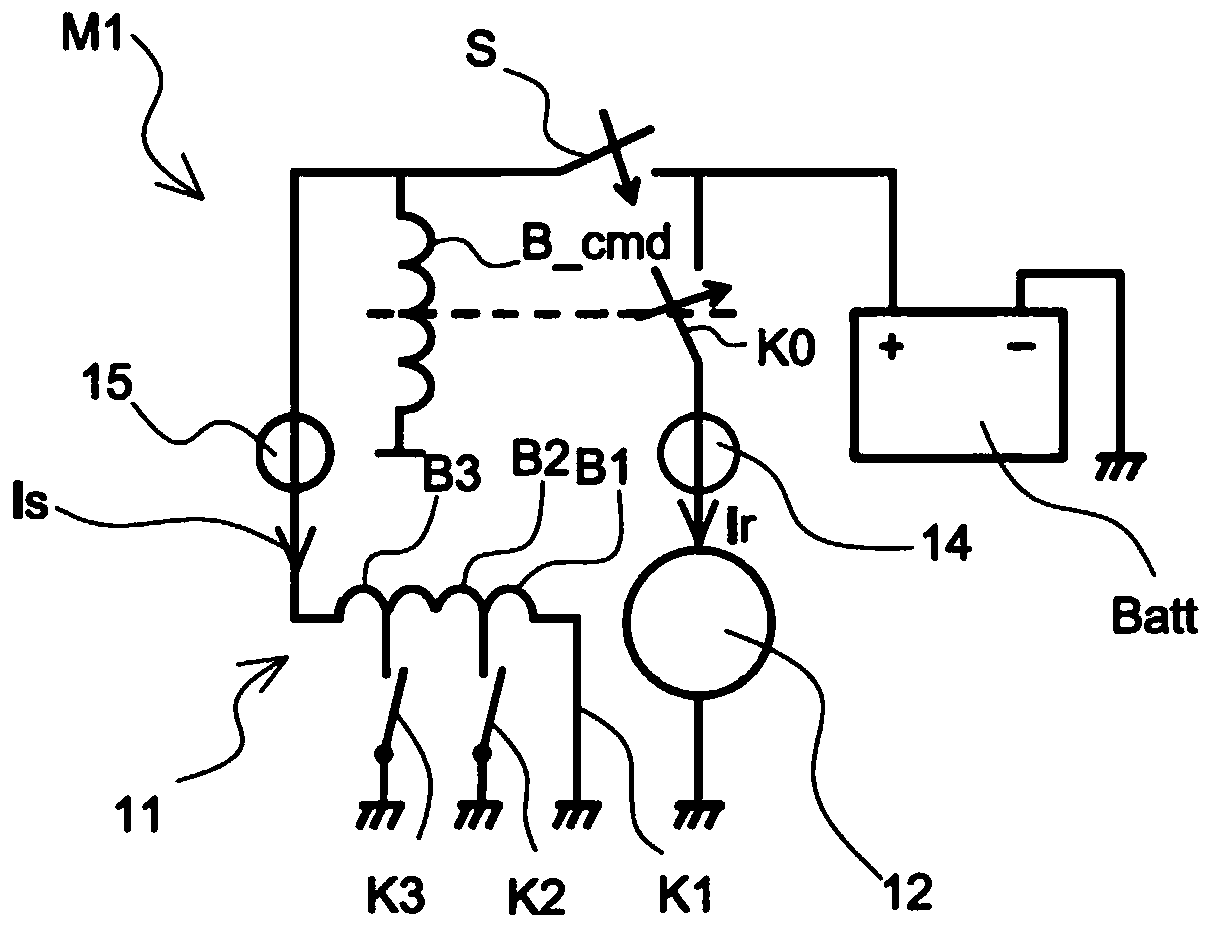

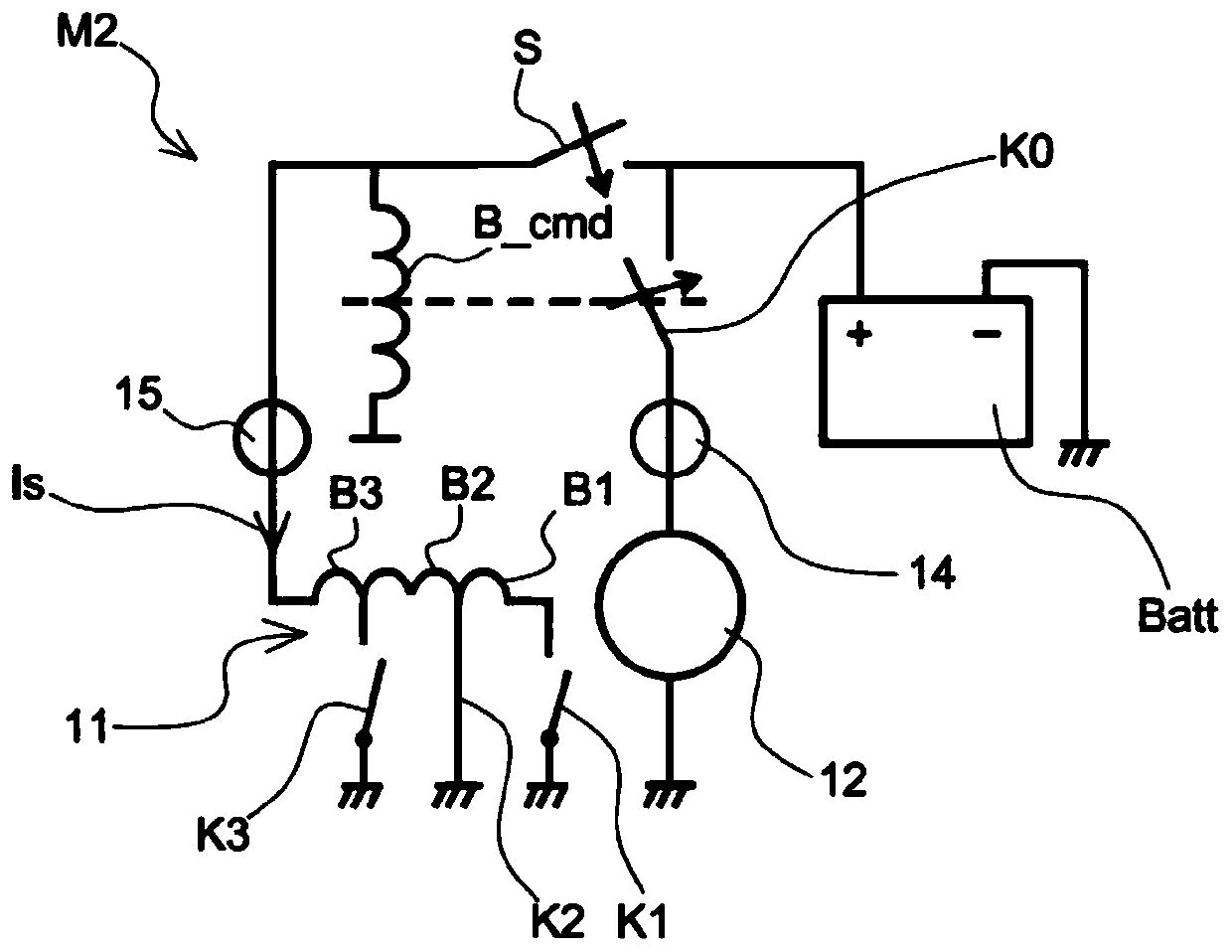

[0038] figure 1 An electric traction machine 10 with direct current and live brushes according to the invention is shown. The motor 10 with winding excitation includes an inductor 11 and an armature 12 . In this case, the armature 12 consists of a rotor provided with windings.

[0039] In addition, the electromagnet contactor is provided with a mechanical power contact K0 belonging together with the armature 12 to the power circuit C_Puis.

[0040] The power contact K0 is controlled by a coil B_cmd belonging to the control circuit C_Com. This circuit C_Com also comprises a contact S, the closing of which commands the activation of the control coil B_cmd, thereby causing the closing of the power contact K0. Electric energy is supplied by the battery Batt, and the power supply voltage is preferably 48V.

[0041] The inductor 11 has a separate winding excitation through which the current Is is independent of the armature current Ir. The inductor 11 is electrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com