Multi-sensor quick dismounting device based on three-coordinate measuring machine and use method

A three-coordinate measuring machine and multi-sensor technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of sensor size, specification restrictions, increased measurement costs, high maintenance costs, etc., to expand the scope of application and save measurement costs , The effect of saving the transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

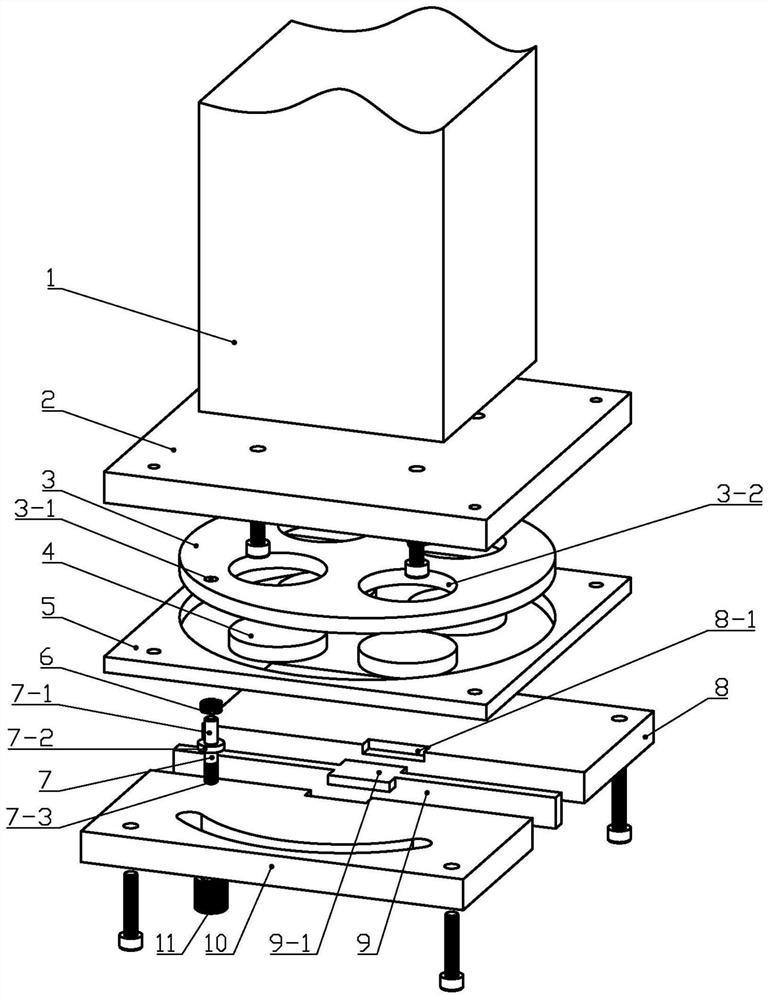

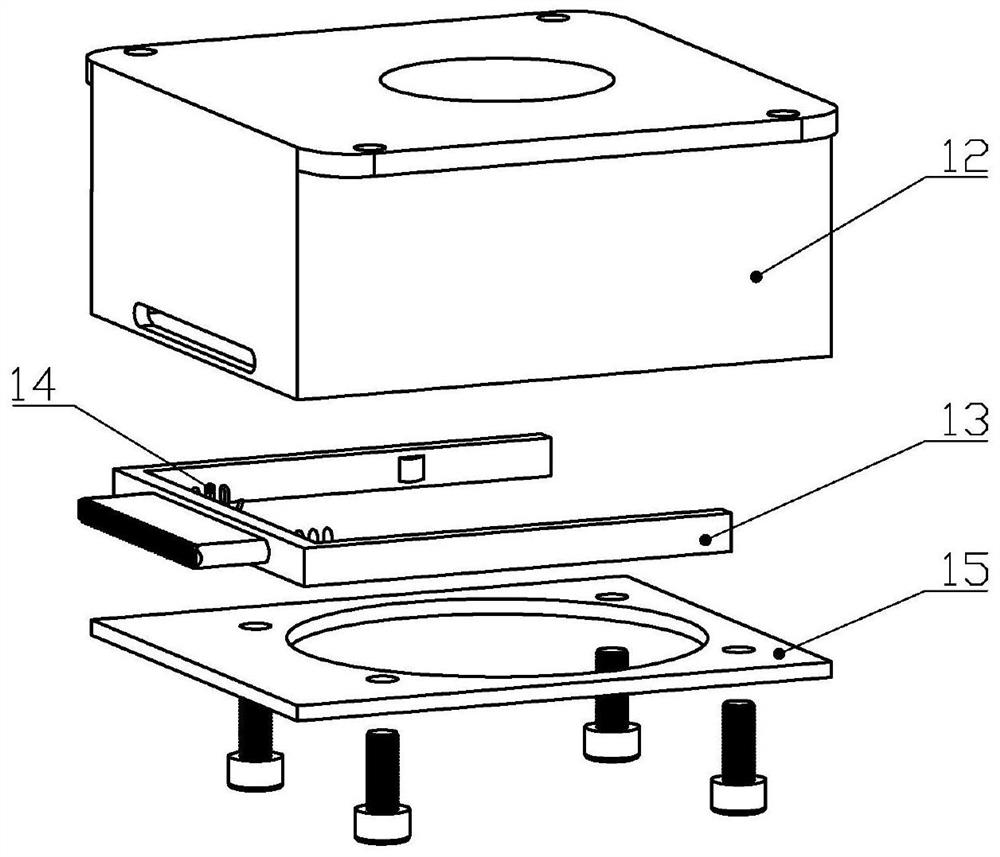

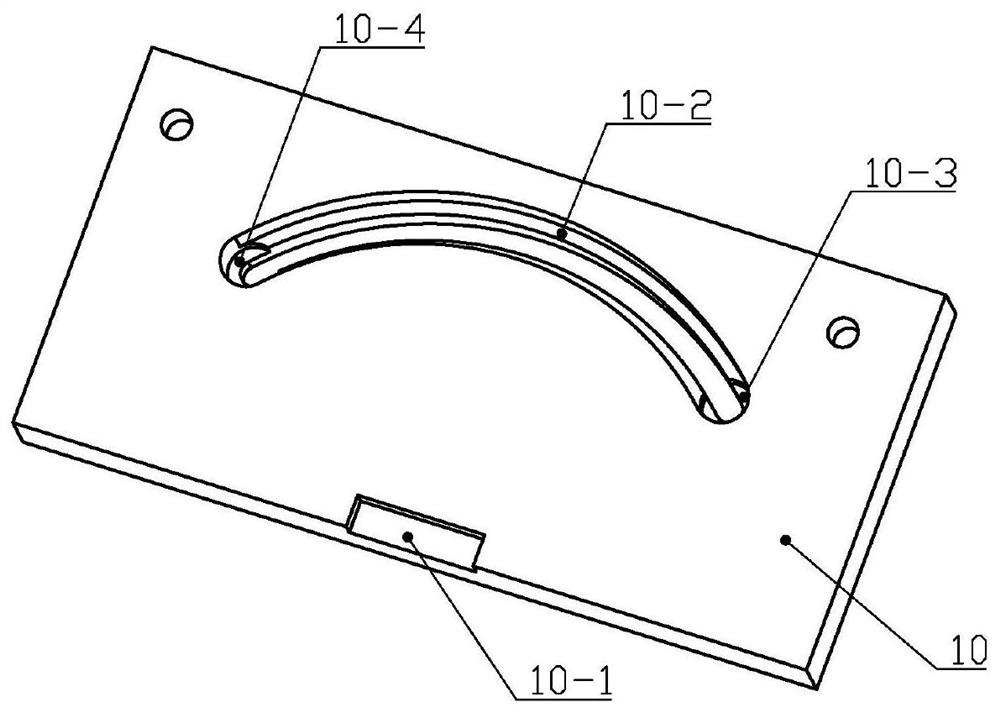

[0038] Such as Figures 1 to 12 As shown, a multi-sensor quick disassembly device based on a three-coordinate measuring machine includes a magnetic base module, a common joint base module and a special joint module connected sequentially from top to bottom. The magnetic base module is fixed on the bottom of the Z-axis 1 of the coordinate measuring machine through screws. The public joint base module is fixedly installed under the magnetic base module by screws. The special connector module is connected with the public connector base module under the magnetic force adsorption of the magnetic base module. After the special joint module is connected with the public joint module under the action of magnetic force, the relative angle between the special joint module and the public joint module can be adjusted in the circumferential direction at intervals of 15° in the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com