Intelligent control method for stirrer

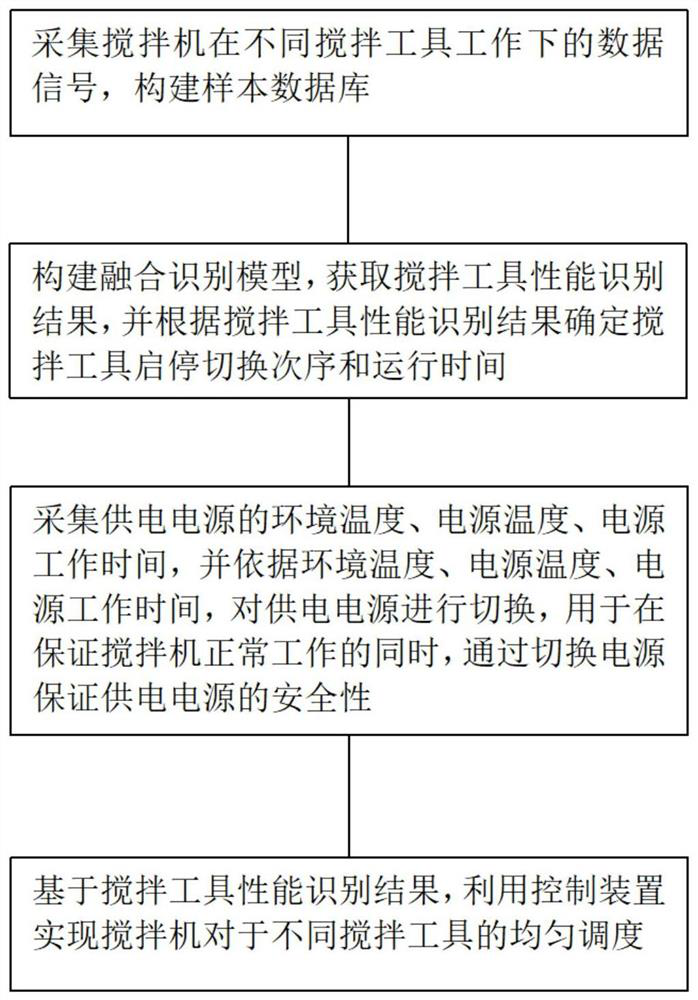

An intelligent control and mixer technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of large mixing tools and sealed tanks, increased equipment costs, uneven mixing, etc., to achieve Improve the stirring effect, prevent frequent switching, and improve the effect of recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: In the present invention, the process of obtaining the performance identification result of the mixer includes:

[0075] 1) According to the membership functions corresponding to at least two stirring tools, obtain a set of vibration, current, acoustic emission and temperature multi-signal sample data of at least two stirring tools respectively, and bring them into the calculated membership function as input data Obtain the membership degree value of vibration signal, current signal, acoustic emission signal and temperature signal;

[0076] 2) Take the obtained membership degree values of vibration signal, current signal, acoustic emission signal and temperature signal as the basic input value of the basic probability distribution function of D-S evidence theory, and then calculate the basic probability of each air compressor value, the fusion model based on D-S evidence theory is used to fuse the multi-featured sample data of vibration, temperature, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com