Cable installation adjusting frame for electric power engineering construction

A cable installation and power engineering technology, applied in the direction of electrical components, etc., can solve the problems of cable damage, the installation frame can not adjust the size of the cable turning radius, etc., to achieve the effect of reducing damage, easy to fix the cable, and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

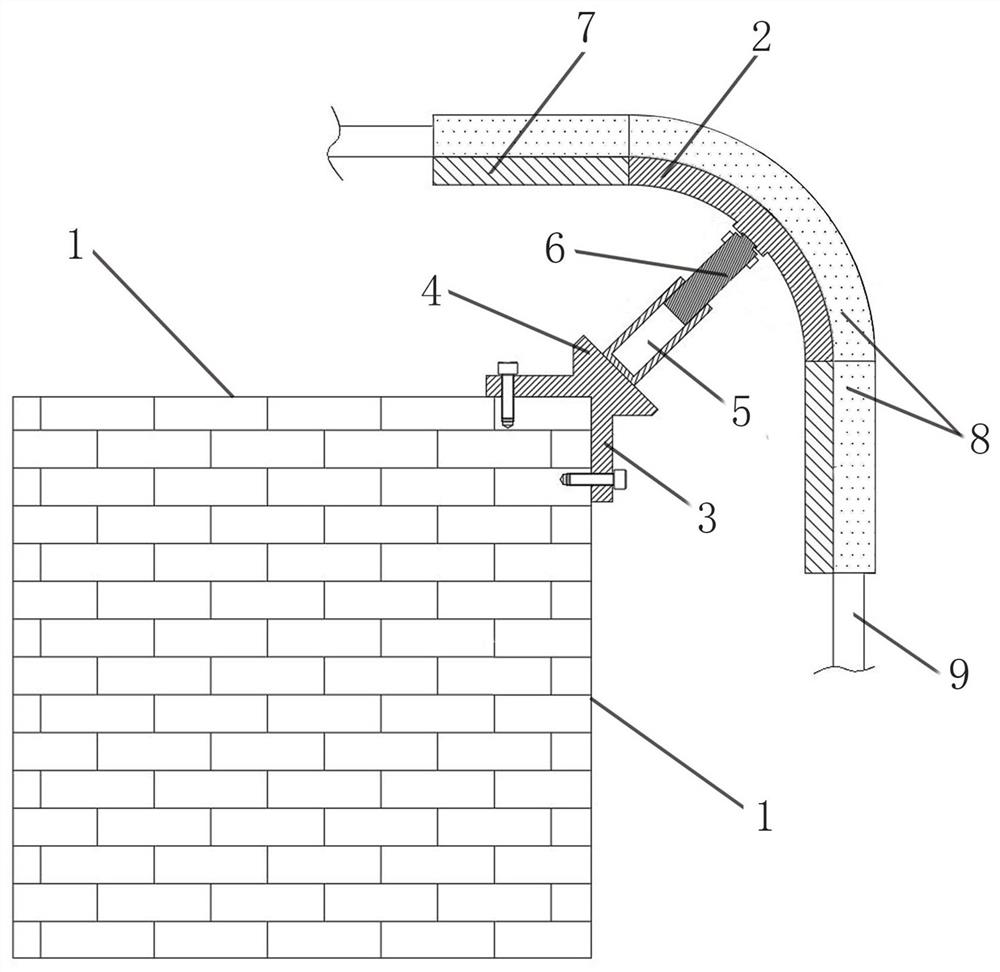

[0033] Embodiment 1 Cable installation and adjustment frame for electric power engineering construction

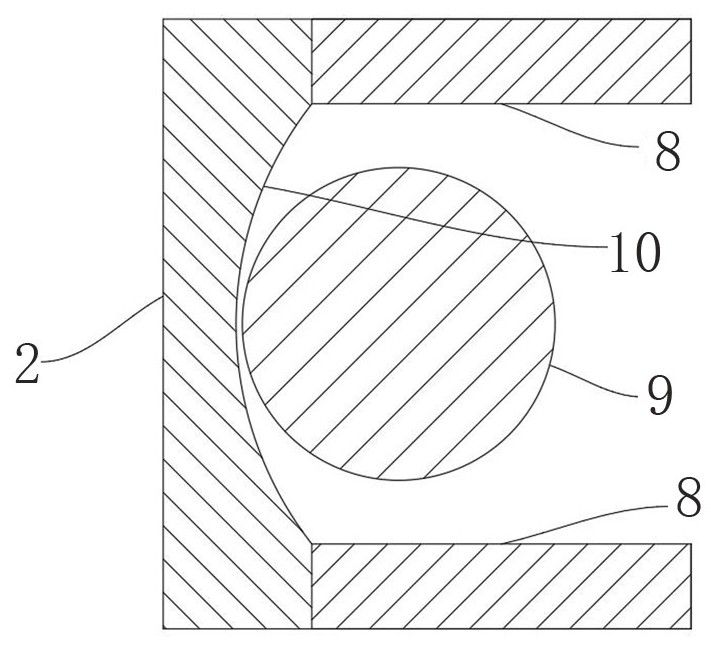

[0034] Such as figure 1 As shown, this embodiment includes a curved plate 2, a fixing part that is detachably connected to the corner of the wall 1, and is arranged between the fixing part and the curved plate 2 for adjusting the curved plate 2 and the wall 1 An adjustment component for the spacing between corners. The angle of the corner of the wall body 1 is 90°, and the fixing part includes two connecting plates 3 detachably connected with the corresponding wall body 1 and a fixing plate 4 fixedly connected with one end of the adjustment assembly, the connecting plate 3 and the fixing plate 4 are integrally formed, Among them, the two connecting plates 3 are installed on the corresponding wall 1 through mounting bolts, the angle between the fixed plate 4 and the wall 1 is 45°, and the other end of the adjustment assembly is connected to the arc plate 2 in rotation, and...

Embodiment 2

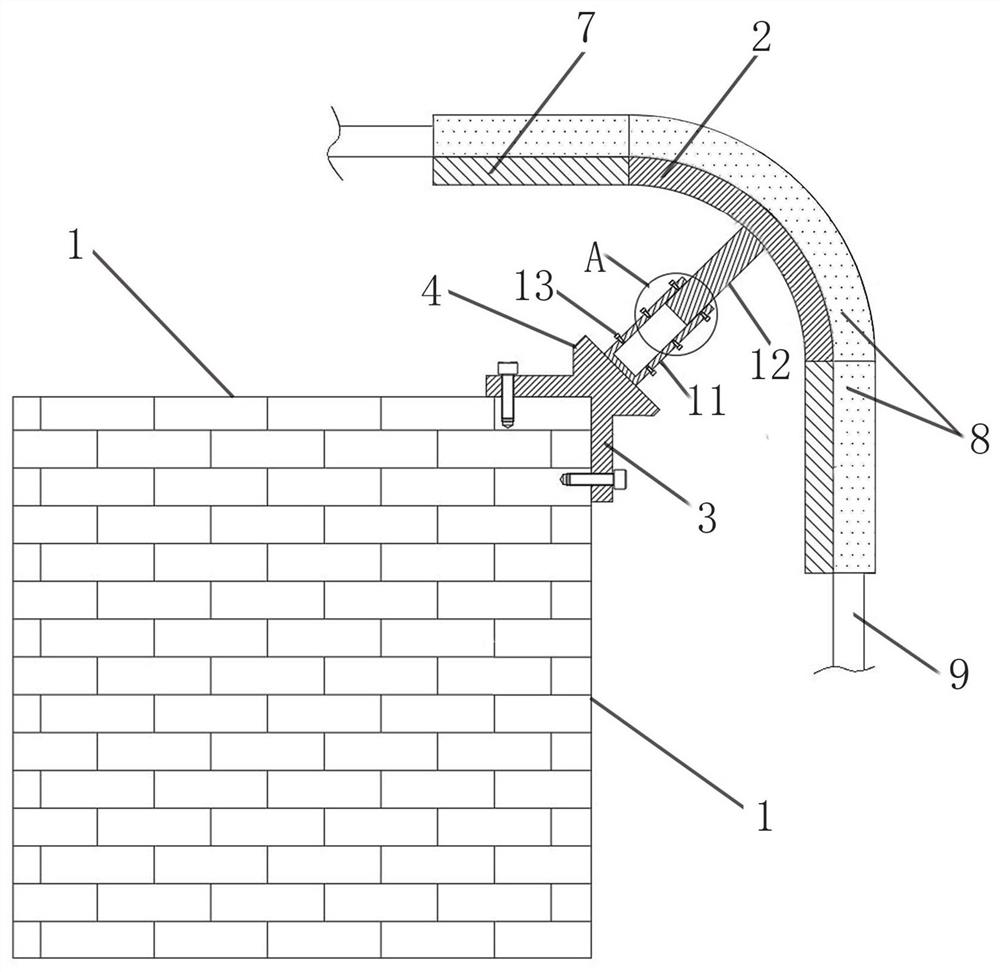

[0040] Embodiment 2 Cable installation and adjustment frame for electric power engineering construction

[0041] Such as image 3 and Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the adjustment assembly includes a sleeve 11 and a sleeve rod 12; wherein, one end of the sleeve 11 is fixedly connected to the fixed plate 4, and one end of the sleeve rod 12 is slidably connected In the casing 11, the other end of the casing rod 12 is rotatably connected to the arc-shaped plate 2, and the side wall of the casing 11 is threaded with a locking bolt 13 for fixing the casing rod 12 in the casing 11. The side wall of 11 is provided with a screw hole matched with the locking bolt 13, and the angle between the casing 11 and the wall 1 is 135°.

[0042] When this embodiment is in use, by pushing and pulling the sleeve rod 12 to make the sleeve rod 12 slide in the sleeve 11, the distance between the arc-shaped pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com