Control method of anti-tear roller

A control method and anti-tearing technology, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of fluctuating inlet tension, local tearing and instability of the steel strip surface, and avoid local tearing, The wrap angle is stable and the effect of avoiding the unstable inlet tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

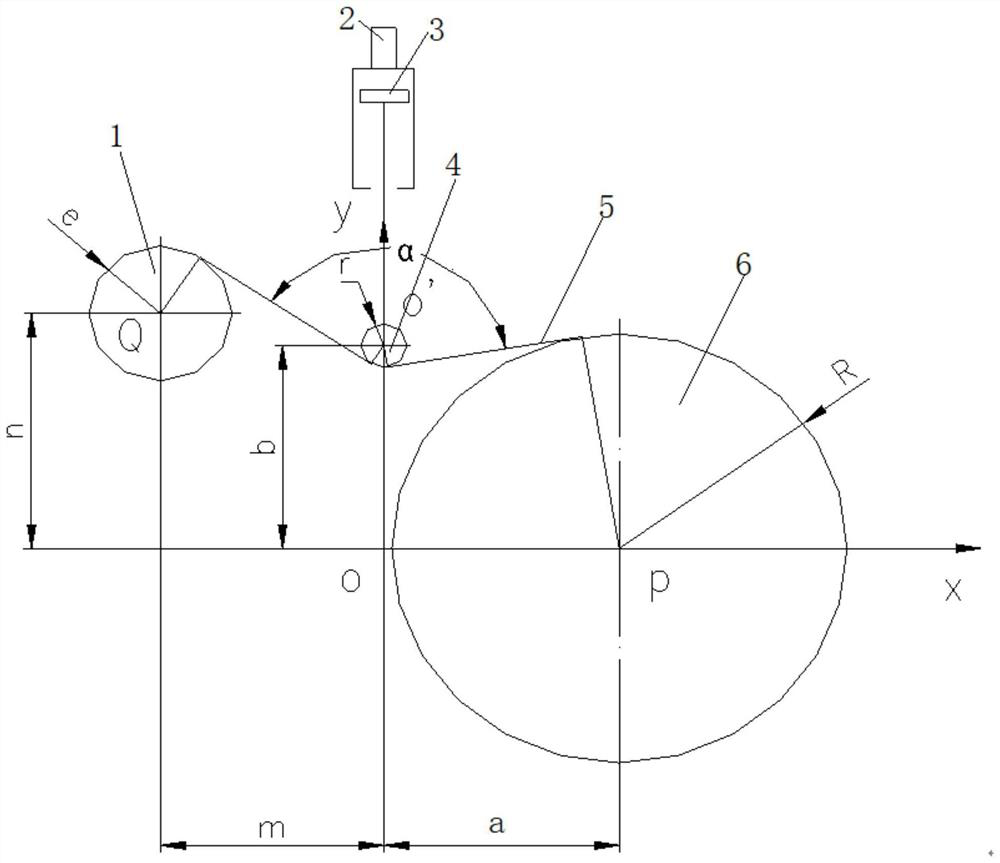

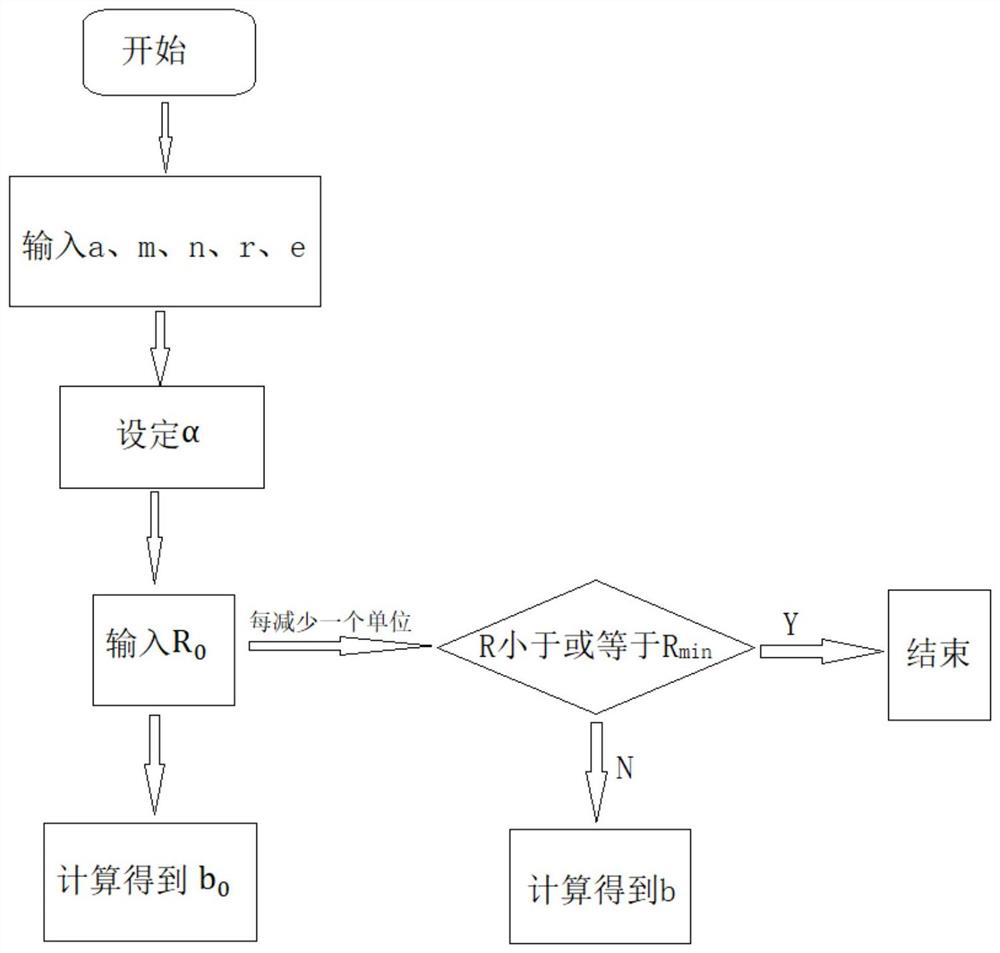

[0019] A control method for anti-tear rolls. During the uncoiling process, real-time detection and uploading of steel coil 6 coil diameters, real-time control of the pressing position of anti-tear rolls 4 through the pressing cylinder 3, according to tension roll 1, anti-tear rolls 4 and the geometric relationship of the steel strip 5 on the uncoiler determine the control target of the pressing cylinder 3, so that the anti-tear roll 4 floats with the coil diameter of the steel coil 6 to ensure that the wrap angle of the steel strip 5 and the anti-tear roll 4 is stable, as figure 1 As shown, in this embodiment, the stroke detection mechanism 2 is fitted on the depression cylinder 3 .

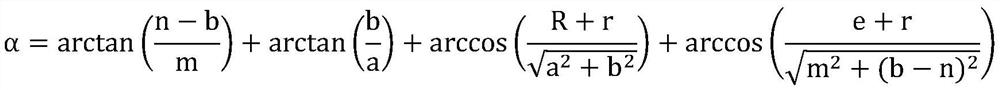

[0020] The calculation formula of the wrap angle α of steel strip 5 and anti-tear roller 4 is:

[0021]

[0022] Among them, such as figure 1 As shown, a is the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com