Method and device for detecting air tightness of aluminum-plastic film of battery

A detection method and technology of detection device, which are applied in the direction of liquid/vacuum measurement for liquid tightness, etc., can solve the problems of micro-cracks of aluminum layer and PP layer, complicated operation, rupture of aluminum-plastic film, etc., so as to shorten the air tightness. time, wide detection range and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

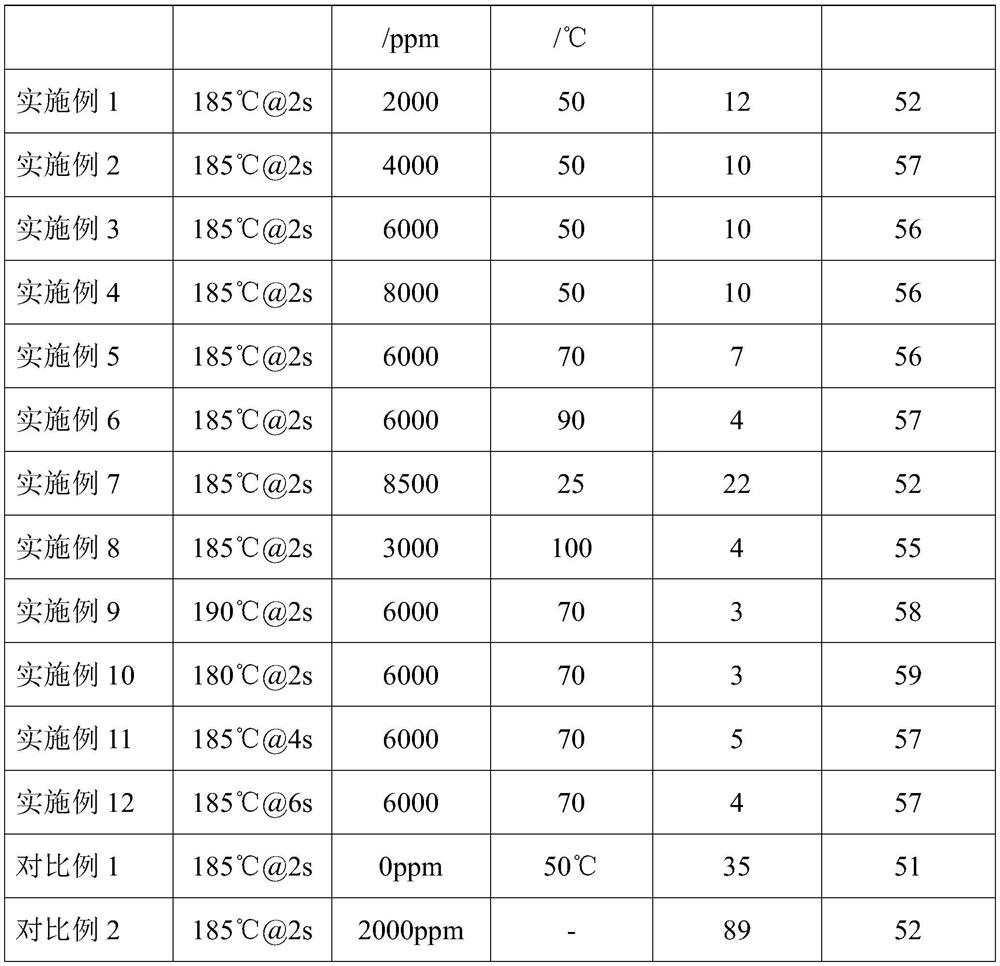

[0061] This embodiment provides a method for detecting the airtightness of the aluminum-plastic film of a battery, and the detection method includes:

[0062] When the battery is packaged, add electrolyte to the battery first and then add water. The amount of electrolyte added is 4% more than the standard electrolyte for battery injection, and the package is completed. The package condition is 185°C@2s. After adding water, the electrolysis The water content in the liquid is 2000ppm, and the packaged battery is placed in a water tank to be heated at a temperature of 50°C. The expansion volume of the battery is recorded, and the airtightness of the battery is tested.

Embodiment 2

[0064] This embodiment provides a method for detecting the airtightness of the aluminum-plastic film of a battery, and the detection method includes:

[0065] When the battery is packaged, add electrolyte to the battery first and then add water. The amount of electrolyte added is 4% more than the standard electrolyte for battery injection, and the package is completed. The package condition is 185°C@2s. After adding water, the electrolysis The water content in the liquid is 4000ppm, and the packaged battery is placed in a water tank to be heated at a temperature of 50°C. The expansion volume of the battery is recorded, and the airtightness of the battery is tested.

Embodiment 3

[0067] This embodiment provides a method for detecting the airtightness of the aluminum-plastic film of a battery, and the detection method includes:

[0068] When the battery is packaged, add electrolyte to the battery first and then add water. The amount of electrolyte added is 4% more than the standard electrolyte for battery injection, and the package is completed. The package condition is 185°C@2s. After adding water, the electrolysis The water content in the liquid is 6000ppm. The packaged battery is placed in a water tank and heated at a temperature of 50°C. The expansion volume of the battery is recorded and the airtightness of the battery is tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com