Stamping processing method and processing mold for fuel tank connecting insert

A technology of stamping processing and fuel tank, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of local stress concentration, easy fatigue fracture, tearing, etc., to avoid mutual adverse effects, avoid local tearing, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

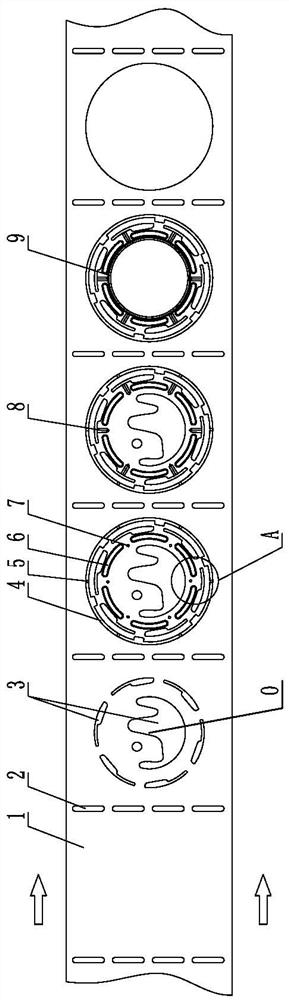

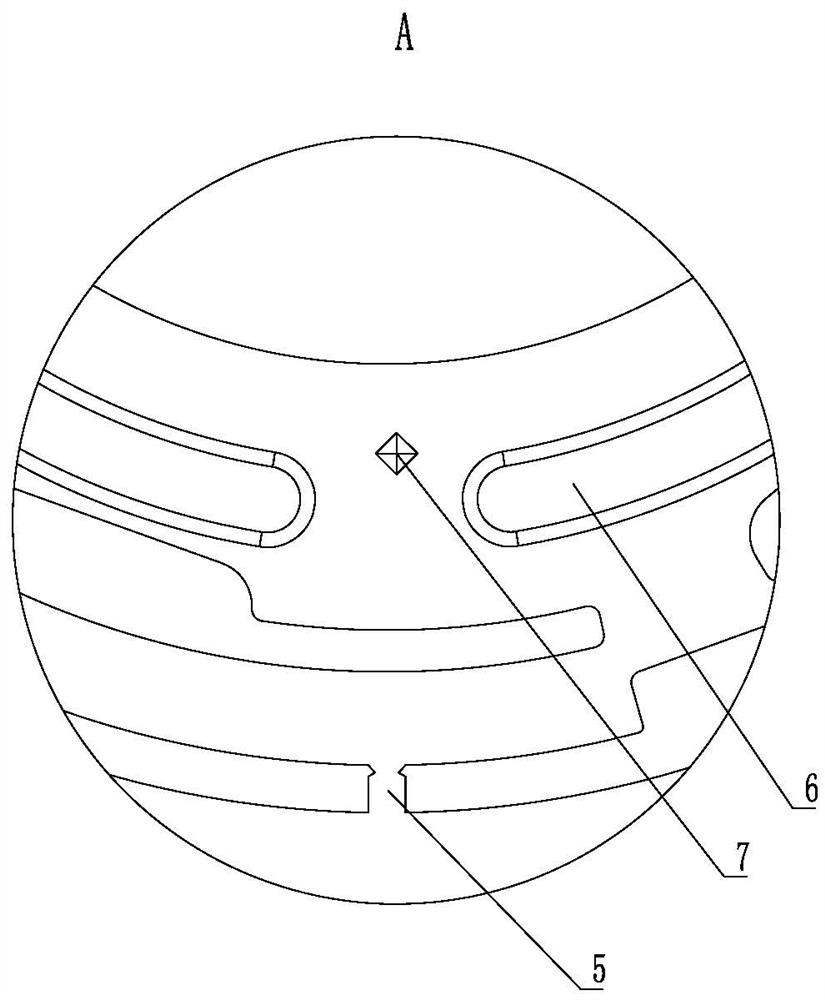

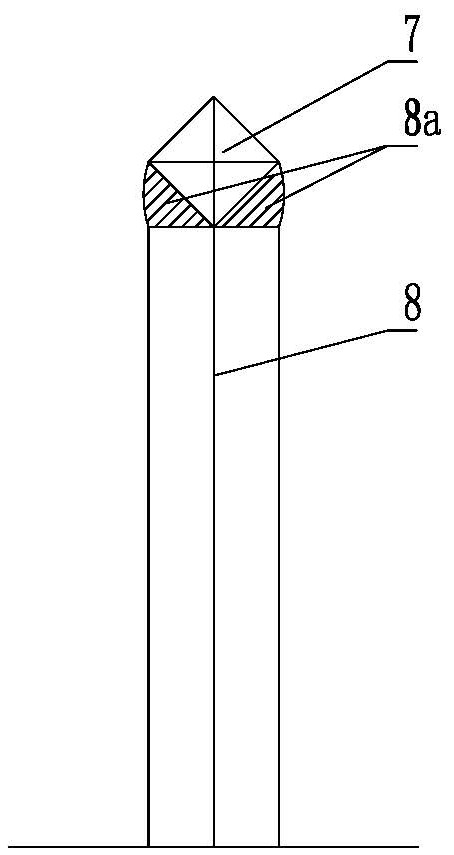

[0031] Such as Figure 1~3 As shown, it is a stamping method for a fuel tank connection insert, which includes the following steps:

[0032] 1) Uncoil, level and pull the coiled material strip 1 into a stamping machine equipped with a progressive die. The material strip 1 moves in one direction in a step-by-step manner, and moves one station each time it moves; the progressive die contains at least Five stations; material strip 1 has a virtual center O for determining the circumferential direction and the radial direction on each station, and the virtual center O is used as the reference point in the circumferential direction and the radial direction, The circumferential direction is the circumferential direction of a circle drawn with the virtual center O as the center, the circle can also be virtual, and the radial direction is the radius or diameter direction of the circle corresponding to the virtual center O as the center.

[0033] 2) Along the traveling direction of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com