Rubber biological machine outsole and preparation method thereof

A biological and rubber technology, applied in shoe soles, plastic recycling, clothing and other directions, can solve the problems of immature plant fiber raw materials, difficulty in improving processing performance, and inability to further break through the comprehensive mechanical properties of products. The effect of the contribution of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

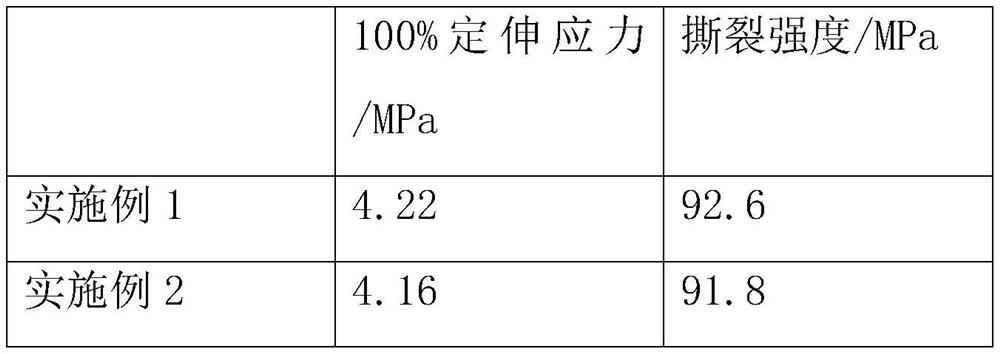

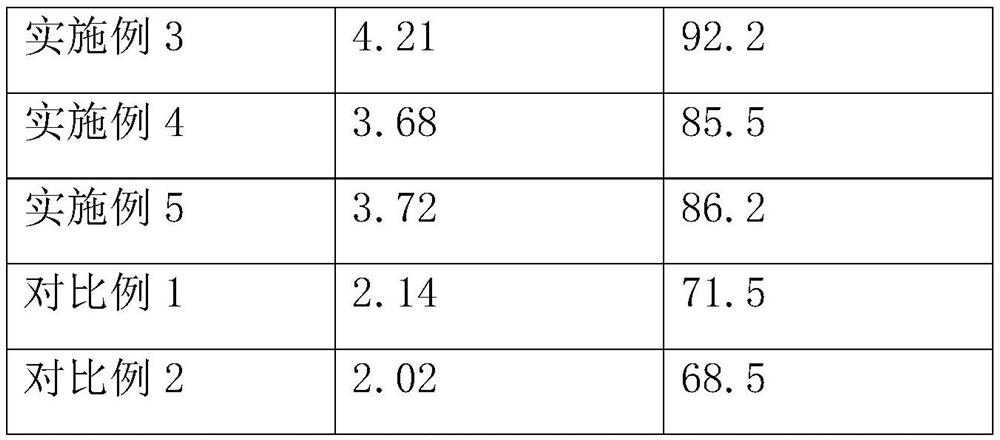

Examples

Embodiment 1

[0031] The plant fiber raw materials were soaked in water for 3 hours at room temperature, and then transferred to the steam explosion tank. Under the condition of temperature of 160 °C and pressure of 2.8 MPa, after heat preservation and pressure maintenance for 1 hour, the steam explosion tank was opened and the pressure was instantly released to 2.8 MPa. At normal pressure, the steam explosion treatment of plant fiber raw materials is completed, the blasting material is collected, and transferred to an oven, and dried to constant weight at a temperature of 100 ° C to obtain steam explosion slag;

[0032] Prepare steam explosion slag, PVDF resin with a mass of 20% of the steam explosion slag, and N-methylpyrrolidone as a solvent with 5 times the mass of the PVDF resin. First, mix and dissolve the PVDF resin and the solvent, and then add nanometer 5% of the mass of the PVDF resin. Alumina particles, then add steam explosion slag, stir and mix with a mixer at 200r / min for 4 hou...

Embodiment 2

[0039] The plant fiber raw materials were soaked in water for 4 hours at room temperature, and then transferred to the steam explosion tank. Under the condition of temperature of 170 °C and pressure of 3.2 MPa, after heat preservation and pressure maintenance for 1.5 hours, the steam explosion tank was opened to release the pressure instantly. to normal pressure, complete the steam explosion treatment of the plant fiber raw material, collect the blasting material, transfer it into an oven, and dry it to a constant weight at a temperature of 105 °C to obtain steam explosion slag;

[0040] Prepare steam explosion slag, PVDF resin with a mass of 25% of the steam explosion slag, and a solvent N-methylpyrrolidone with a mass of 7 times the mass of the PVDF resin. After the PVDF resin and the solvent are mixed and dissolved, add nanometer 8% of the mass of the PVDF resin. Alumina particles, then add steam explosion slag, stir and mix with a mixer at 300r / min for 5 hours, then transfe...

Embodiment 3

[0047]The plant fiber raw materials were soaked in water for 5 hours at room temperature, and then transferred to the steam explosion tank. Under the condition of temperature of 180 ° C and pressure of 3.5 MPa, after heat preservation and pressure maintenance for 2 hours, the steam explosion tank was opened, and the pressure was instantly released to 3.5 MPa. At normal pressure, the steam explosion treatment of plant fiber raw materials is completed, the blasting material is collected, and transferred to an oven, and dried to constant weight at a temperature of 110 ° C to obtain steam explosion slag;

[0048] Prepare steam explosion slag, PVDF resin with a mass of 30% of the steam explosion slag, and N-methylpyrrolidone as a solvent with 8 times the mass of the PVDF resin. After mixing and dissolving the PVDF resin and the solvent, add nanometer 10% of the PVDF resin mass. Alumina particles, then add steam explosion slag, stir and mix with a mixer at 400r / min for 6 hours, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com