Torsion spring two-end machining device and method and torsion driving device

A processing device and torsion spring technology, applied in the field of torsion spring processing, can solve problems such as reducing the processing efficiency of torsion springs, and achieve the effects of reducing quantity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

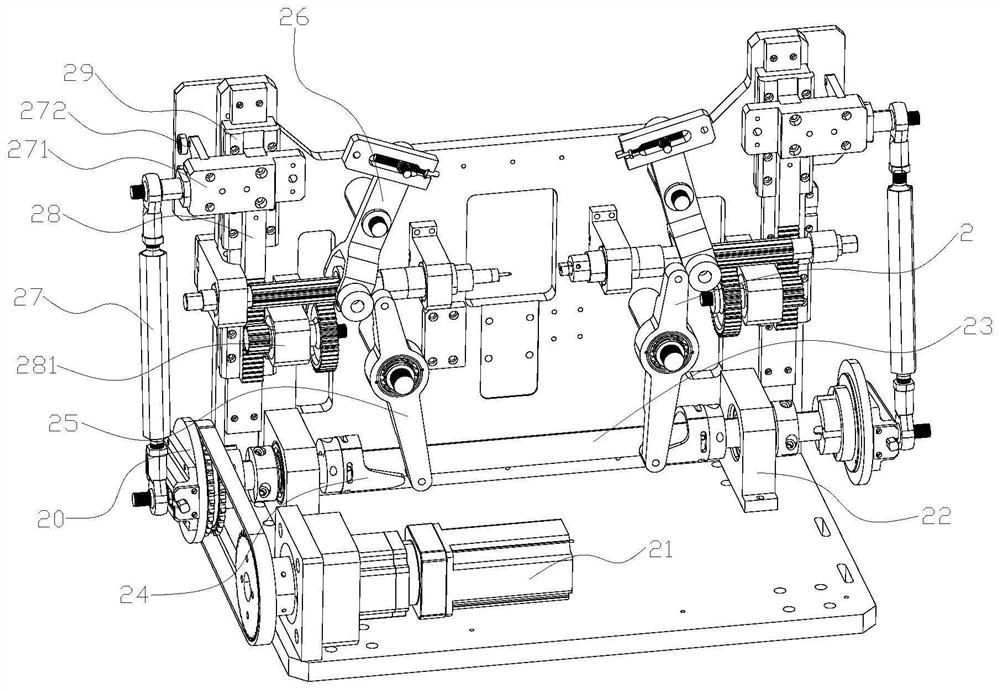

[0026] like figure 1 A torsion spring drive torsion device, including the pusher driving device 2 and the two end processing apparatus 3; the push rod driving device 2 drives the end of the two-end processing apparatus 3; two-end processing device 3 processing ends and spring, respectively The two ends of the steel are in contact.

[0027] The product flow direction of the torsion spring is: the push rod drive 2 to both end processing apparatus 3.

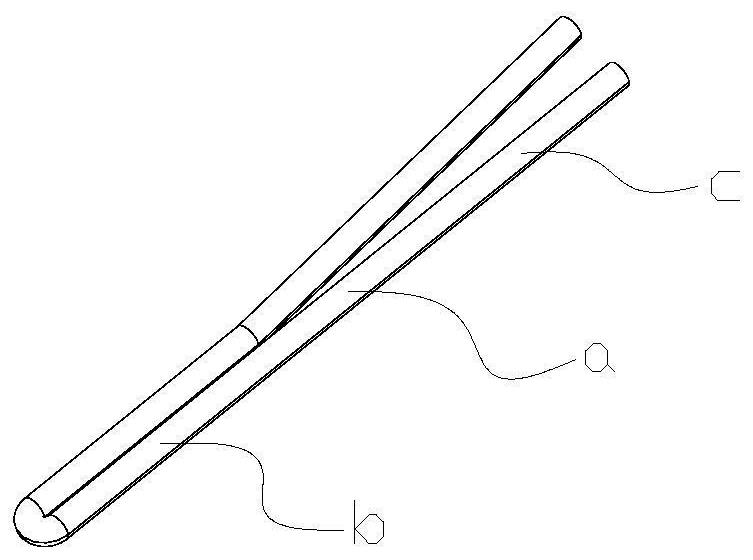

[0028] like figure 2 The structure is shown in the product structure of the folded spring steel A. The folded spring steel A includes the folded end B and the opening end C, the upper clamping device 1 clamps the folded end B, and the two-terminal processing apparatus 3 respectively contacts two segments after the opening end C. and then processes it. .

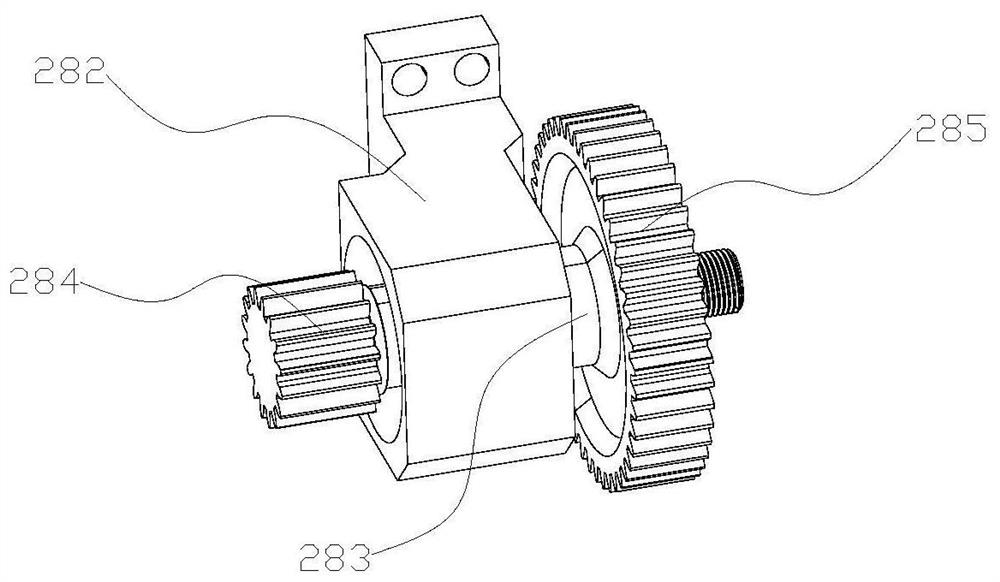

[0029] like figure 1 As shown, the push rod drive device 2 includes a drive motor 21, a bearing base 22, a drive shaft 23, a driving cam 24, a first link 25, a fork 26, a second link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com