Endoscope water vapor removal method and structure

An endoscope and water vapor technology, applied in the field of endoscope, can solve problems such as equipment performance damage and difficult disassembly process, and achieve the effects of reducing maintenance costs, ensuring clarity, and extending service life

Pending Publication Date: 2022-01-21

JOYMEDICARE (SHANGHAI) MEDICAL ELECTRONIC TECH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the endoscope itself is designed as a strictly closed system, the disassembly process is very difficul

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

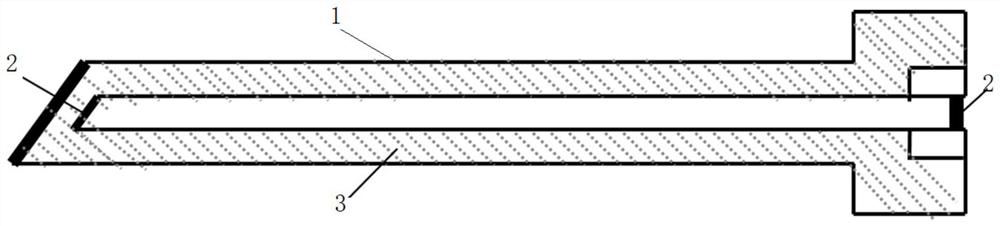

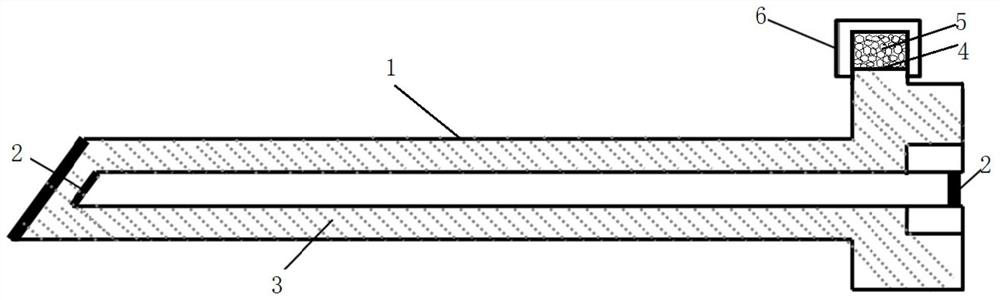

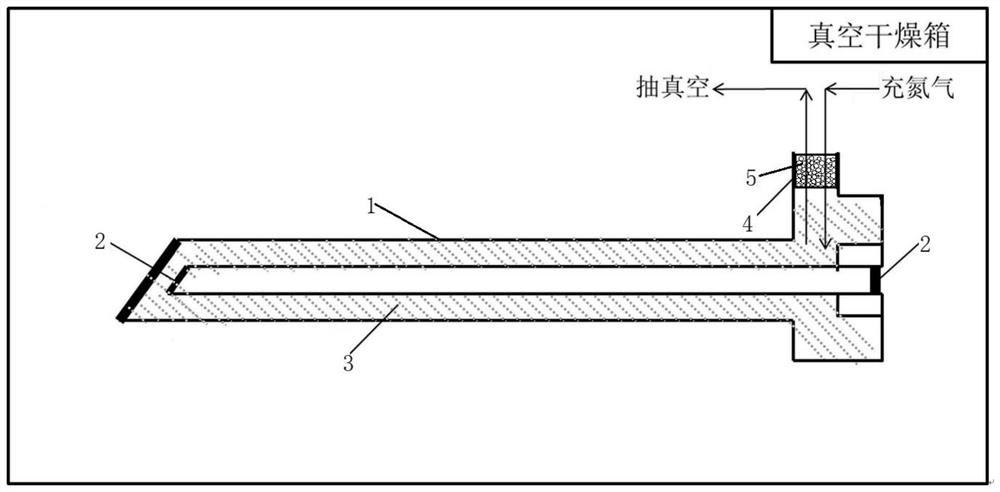

The invention discloses an endoscope water vapor removal method and structure. A water absorption filter head communicating with an internal cavity and the external environment is mounted at the rear end of an endoscope tube of an endoscope, and comprises box bodies and water removal particles, wherein each box body is provided with an air hole and can be opened and closed, and the water removal particles are stuffed in the box bodies and have the capacity of adsorbing volatile substances; at ordinary times, the water absorption filter head is sealed by sealing bolts screwed on an endoscope tube; and when water is removed, the sealing bolts are unscrewed, the endoscope is heated, it is ensured that volatile substances in the endoscope tube are in a gaseous state, nitrogen is continuously injected into the endoscope tube through a water absorption filter head, and original air in the endoscope tube is replaced with dry nitrogen. According to the invention, the nitrogen is used for replacing air in the tube as a core, water vapor and other volatile small molecular substances accumulated in the use process of the endoscope are quickly removed through the water absorption filter head, and the nitrogen is dried in the replacement process, so that the definition of an endoscope head is ensured, and the cost increase and equipment damage caused by disassembly and maintenance are avoided.

Description

technical field [0001] The invention belongs to the field of endoscopes, in particular to a method and structure for removing moisture from an endoscope. Background technique [0002] Endoscopes rely on optical lenses for imaging. The cleanliness of the lens has a very direct impact on the clarity of the image. When water vapor adheres to and condenses on the lens, the lens will become blurred. In order to avoid the influence of water vapor, the endoscope needs to be specially dewatered during assembly, and it must be strictly sealed after completion to avoid water vapor intrusion during subsequent use. However, in actual use, this sealing effect is difficult to maintain all the time. The main reasons are: 1) The position of the welded seal will corrode after contact with the human body environment, or a slight crack will occur due to impact during use; 2) Glue seal After being sterilized by ozone / plasma / high temperature and high pressure, a certain degree of aging and dena...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61B1/12

CPCA61B1/123A61B1/128A61B1/127

Inventor 不公告发明人

Owner JOYMEDICARE (SHANGHAI) MEDICAL ELECTRONIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com