A high-speed vacuum filling and protective gas device

A technology of vacuuming and protecting gas, applied in the direction of packaging under vacuum/special atmosphere, etc., can solve the problems of reducing the service life of the sealing ring and low flexibility, and achieve the effect of ensuring quality, reducing risks, and not easy to accumulate powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

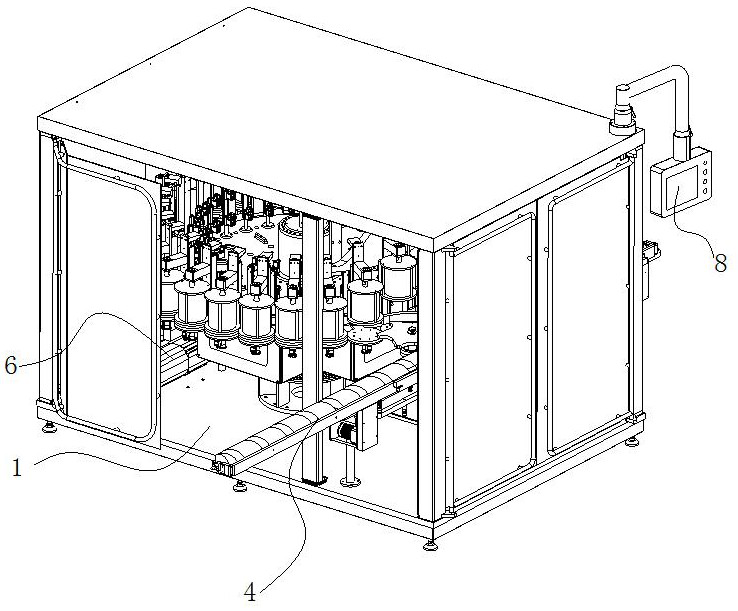

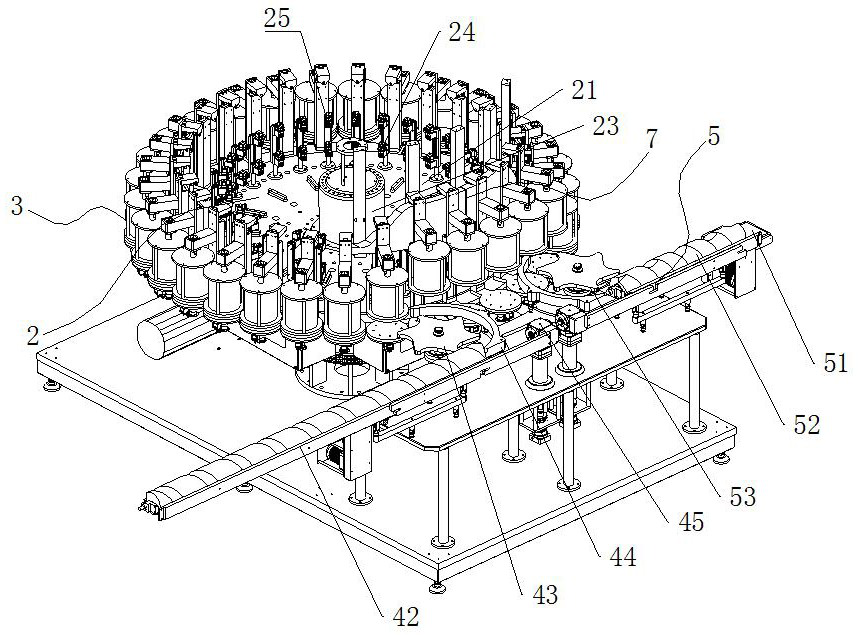

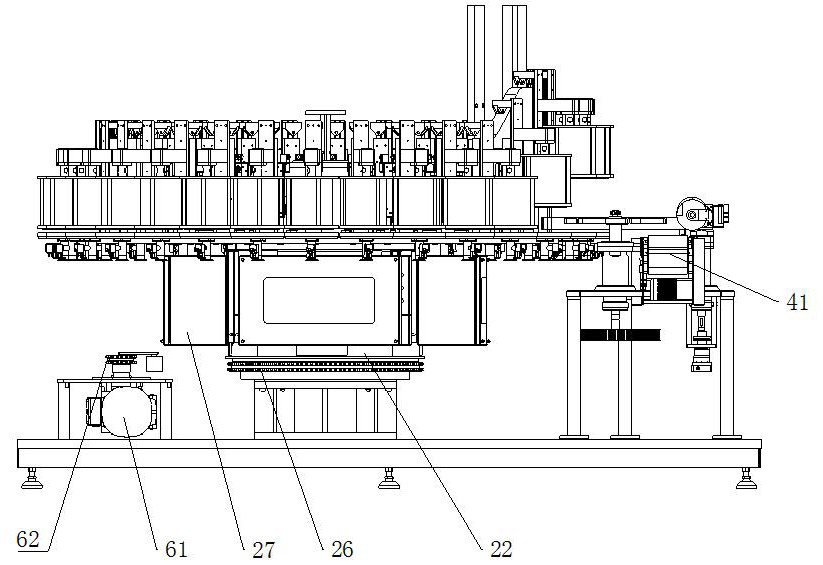

[0038] See Figure 1 to Figure 3 The present invention has a frame 1, a rotating column part 2, a vacuum cover assembly 3, a tank inlet part 4, a tank outlet part 5, a driving part 6, a lifting track 7, and a control part 8. The frame 1 is fixed on the ground; the rotating column The part 2 is rotatably arranged on the bottom frame of the frame 1; there are several vacuum cover assemblies 3, which are evenly arranged around the rotating column part 2; the tank inlet part 4 is horizontally arranged on the side of the rotating column part 2; the tank outlet part 5 It is horizontally arranged on one side of the rotating column part 2; the driving part 6 is arranged on the frame 1 and is driven and connected with the rotating column part 2; the lifting track 7 is arranged outside the rotating column part 2, next to the vacuum cover assembly 3, and fixed Under the top frame of the frame 1; the control part 8 is electrically connected and controlled with the rotating column part 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com