Range hood and control method thereof

A technology for range hoods and range hoods, which is applied in the direction of oil fume removal, heating methods, lighting and heating equipment, etc., and can solve the problems of smoke from the external test stove and poor smoking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

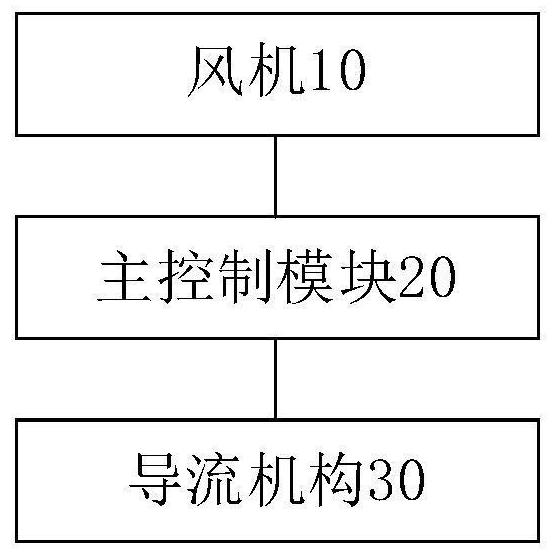

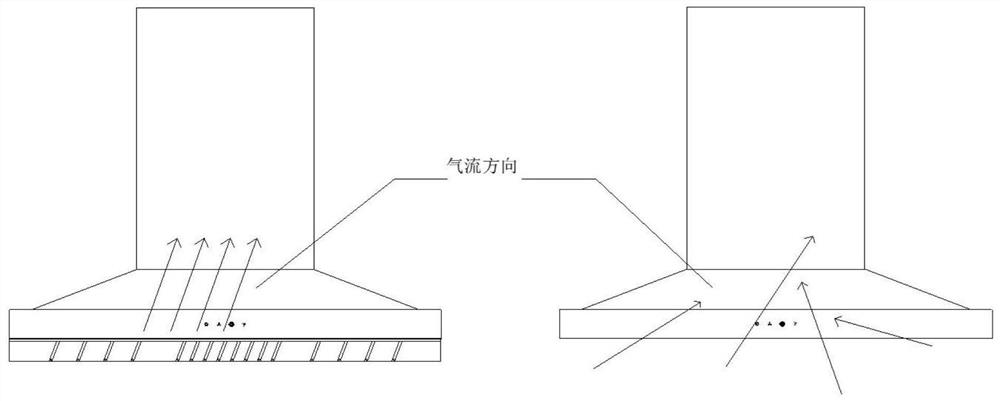

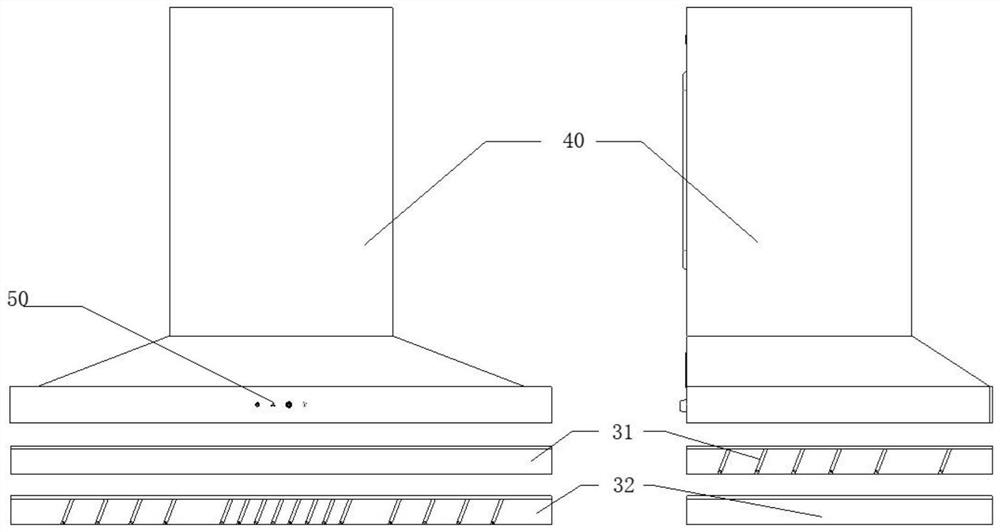

[0031] figure 1 A structural block diagram of a range hood provided by the present invention, such as figure 1 As shown, the range hood includes: a hood cavity 40 ( figure 1 Not shown in ) and fan 10 , the fan 10 is installed in the hood cavity 40 , the range hood also includes: a main control module 20 and a flow guiding mechanism 30 .

[0032] The main control module 20 is respectively connected with the fan 10 and the flow guiding mechanism 30 ; the flow guiding mechanism 30 is installed at the air inlet below the hood cavity 40 .

[0033] The main control module 20 is used for determining the wind force adjustment command and the direction adjustment command based on the target parameters of the stove, and sending the wind force adjustment command to the blower 10 , and sending the direction adjustment command to the flow guiding mechanism 30 .

[0034] The fan 10 is used to adjust the operating wind power according to the wind power adjustment command.

[0035] The air...

Embodiment 2

[0069] The embodiment of the present invention also provides a control method of the range hood, the control method of the range hood is applied to implement the range hood provided in the first embodiment above, the control method of the range hood provided in the embodiment of the present invention is as follows Make a specific introduction.

[0070] Figure 6 A flow chart of a control method for a range hood provided in an embodiment of the present invention, as shown in Figure 6 As shown, the control method specifically includes the following steps:

[0071] Step S102, monitoring the target parameters of each burner in the cooker.

[0072] Wherein, the target parameter includes at least one of the following: smoke concentration, operating power, and soot amount.

[0073] Step S104, based on the target parameters, it is judged whether the direction of the air inlet of the range hood is aligned with the stove with the greatest wind demand.

[0074] Wherein, the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com