Enameled wire pinhole defect detection method

A defect detection and enameled wire technology, applied in the direction of measuring electricity, measuring device, only measuring current, etc., can solve the problems of less data dimension, limited ability to improve the accuracy and reliability of enameled wire defect detection, etc., to increase the dimension of information, improve The effect of precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

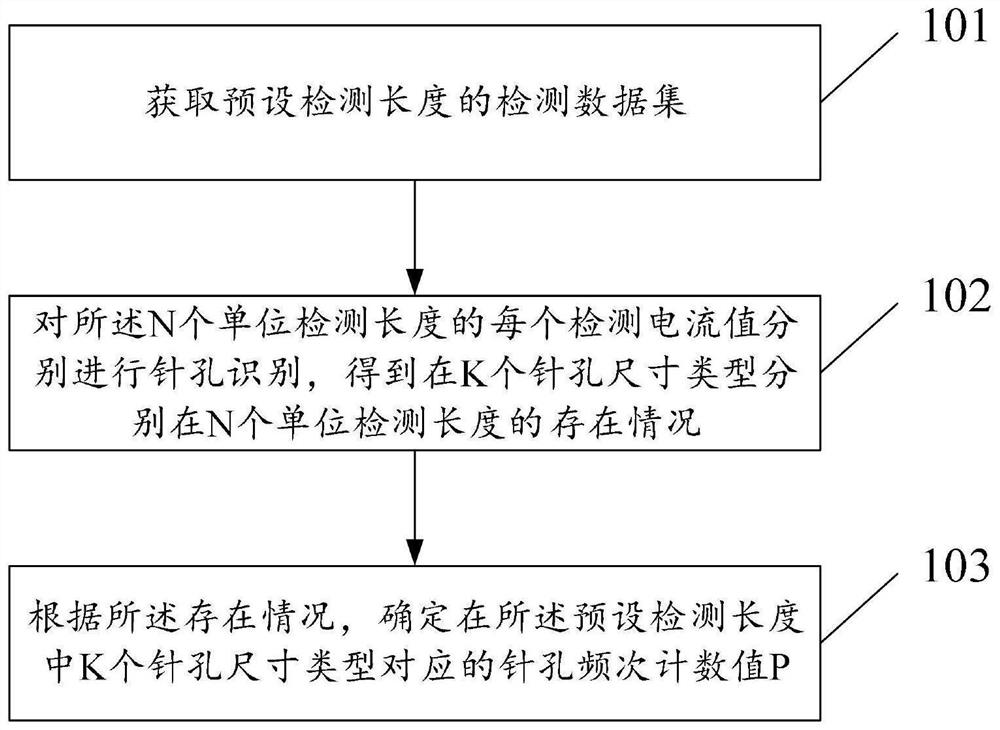

Embodiment 1

[0065] The patent document with the notification number CN109142445B provides an online defect detection method for enameled wire, which judges whether a defect with preset defect conditions occurs within the length of the detection unit on the surface of the currently detected enameled wire, and if so, sends an alarm message; Assume that the defect condition includes at least one of the following: the number of first particles larger than the first particle size is greater than the first value, and the number of second particles larger than the second particle size and smaller than the first particle size is greater than the second value.

[0066] Although the above scheme distinguishes and counts different defect sizes, and sets different judgment thresholds for enameled wire defect detection according to different defect sizes, it only incorporates the information of one dimension of defect quantity into the detection basis for defect detection The data dimension of the judg...

Embodiment 2

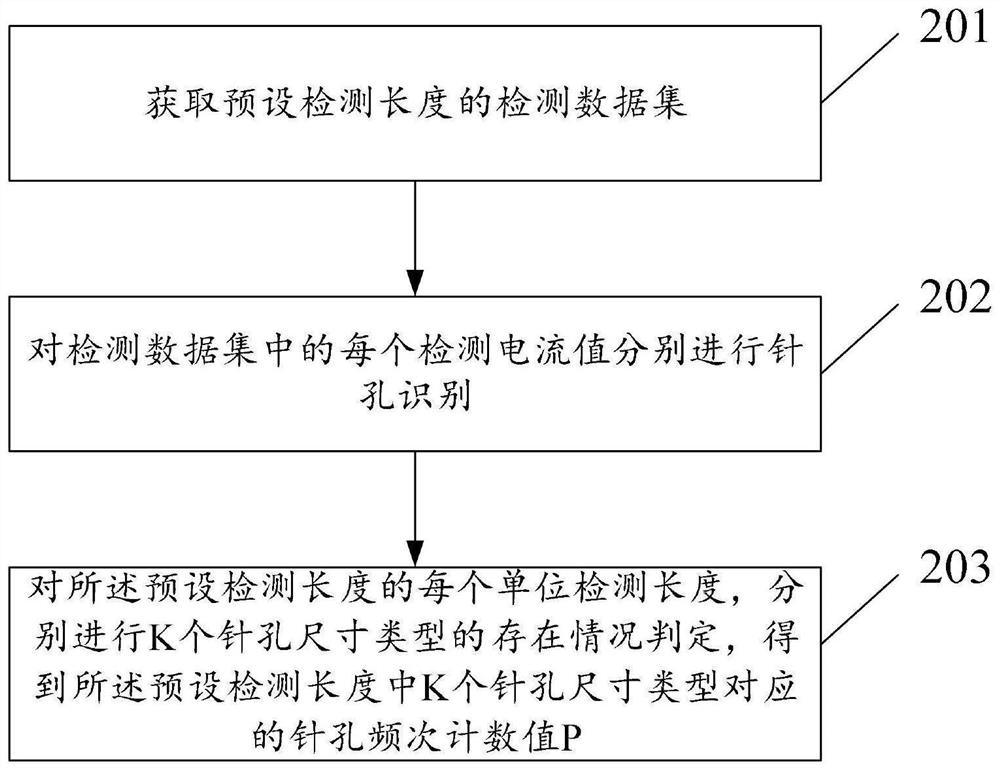

[0089] The embodiment of the present application provides another embodiment of the enameled wire pinhole defect detection method so that those skilled in the art can understand the solution.

[0090] In the embodiment of the present application, the K pinhole size types in Embodiment 1 include: super large pinhole, large pinhole, small pinhole and no pinhole; correspondingly, the pinhole count value includes: super large pinhole count value , a large pinhole count value and a small pinhole count value; correspondingly, the pinhole frequency count value includes: a super large pinhole frequency count value, a large pinhole frequency count value and a small pinhole frequency count value.

[0091] The following will combine figure 2 Describe in detail.

[0092] See figure 2 , the enameled wire pinhole defect detection method, comprising:

[0093] 201. Obtain a detection data set with a preset detection length;

[0094] Wherein, the detection data set includes: N detection ...

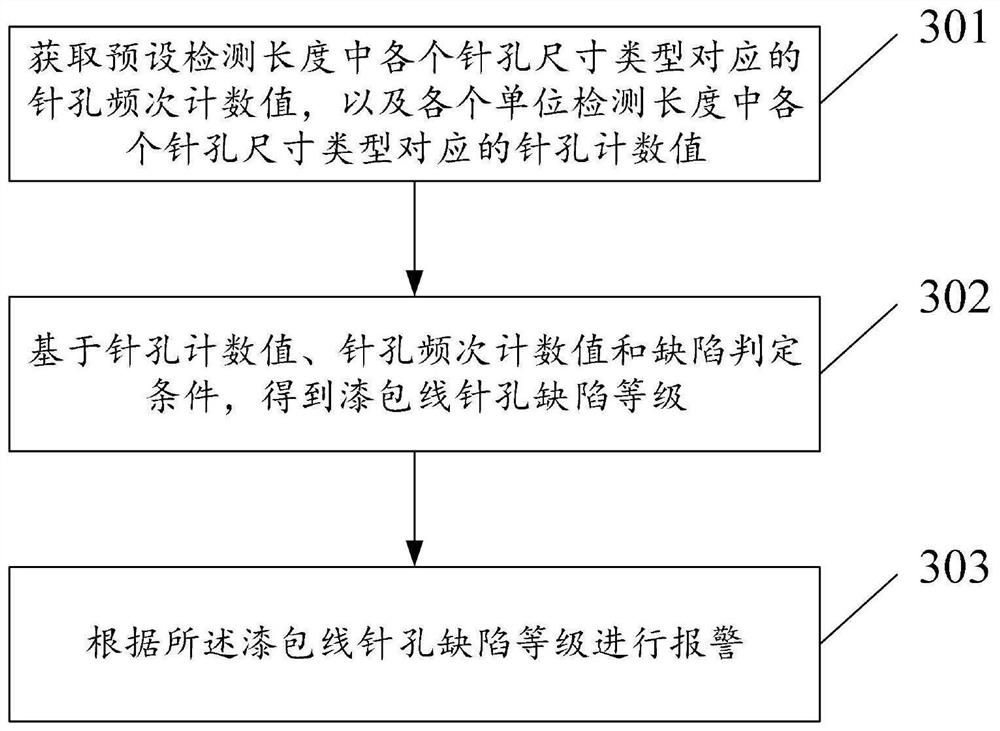

Embodiment 3

[0118] On the basis of obtaining the pinhole count value and the pinhole frequency count value through the enameled wire pinhole defect detection method of the second embodiment above, the embodiment of the present application provides a combination of the pinhole count value and the pinhole frequency count value to detect enameled wire A method for detecting and judging pinhole defects.

[0119] The following combination image 3 Describe in detail.

[0120] See image 3 , the method for detecting and judging enameled wire pinhole defects, comprising:

[0121]301. Obtain the pinhole frequency count value corresponding to each pinhole size type in the preset detection length, and the pinhole count value corresponding to each pinhole size type in each unit detection length;

[0122] In the embodiment of the present application, the pinhole frequency count value corresponding to each pinhole size type in the preset detection length, and the pinhole count value corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com