Aviation insulating material modification method capable of improving flashover voltage and test system thereof

An insulating material and flashover voltage technology, which is applied in the field of aviation insulating material modification methods and test systems, can solve the problems of increasing surface roughness, reducing breakdown voltage, changing the surface condition of materials, etc., achieving accurate and reliable results and improving The effect of flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

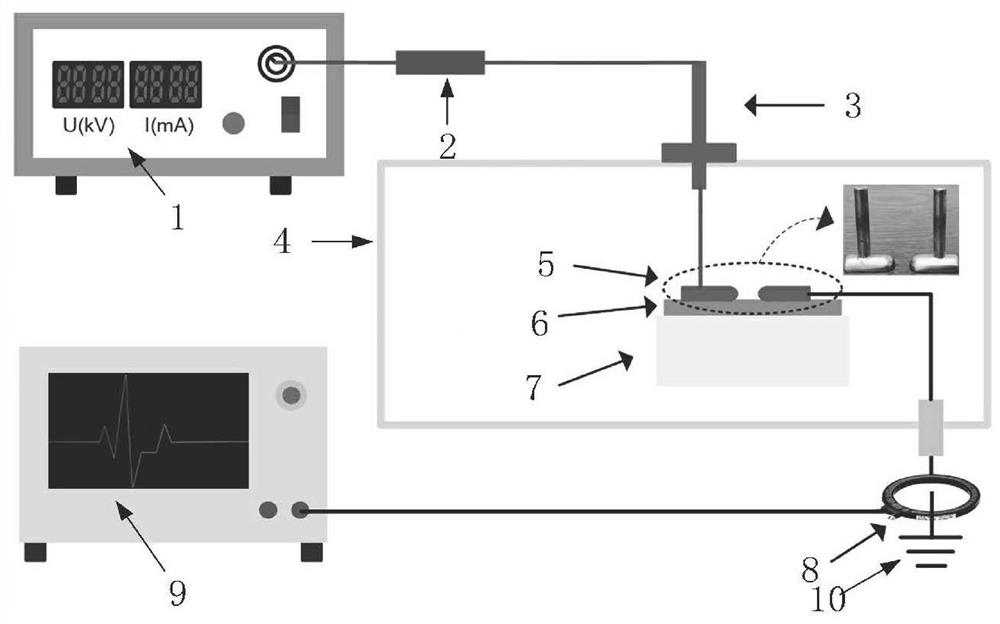

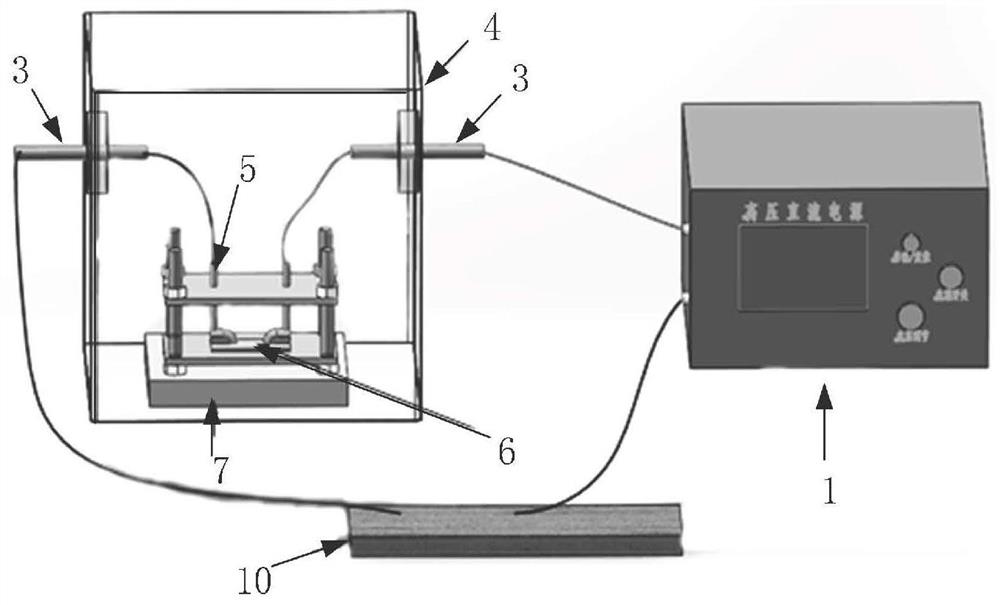

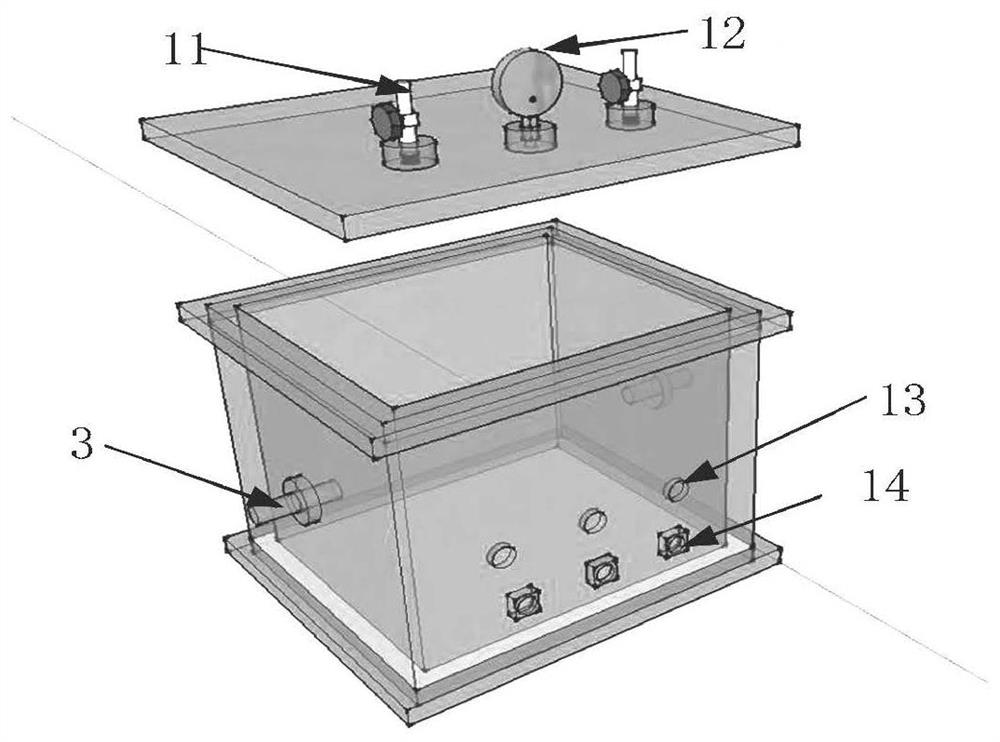

[0046] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0047] A method for modifying aerospace insulating materials capable of increasing flashover voltage, comprising the following steps:

[0048] Step 1, pretreating the aviation insulating material sample;

[0049] The concrete steps of described step 1 include:

[0050] (1) Prepare a PEEK insulating material sample film with a length and width of 20-30mm and a thickness of 90-110um;

[0051] In this embodiment, preferably: prepare a PEEK insulating material sample film with a length and width of 25mm and a thickness of 100um;

[0052] (2) pretreating the aviation insulating material sample film prepared in step (1), for removing surface dirt and keeping it clean;

[0053] The specific steps of the step 1 (2) step include:

[0054] 1. Ultrasonically treat the aviation insulating material sample film in step 1 (1) in absolute ethanol and distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com