Optical lens, camera module, electronic device and automobile

A technology of optical lens and camera module, which is applied in the field of electronic equipment and automobiles, optical lens, and camera module, which can solve the problems of unsatisfactory vehicle lens imaging quality, large head diameter, and insufficient aperture, so as to reduce glue sensitivity brightness, increasing relative illuminance, large aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

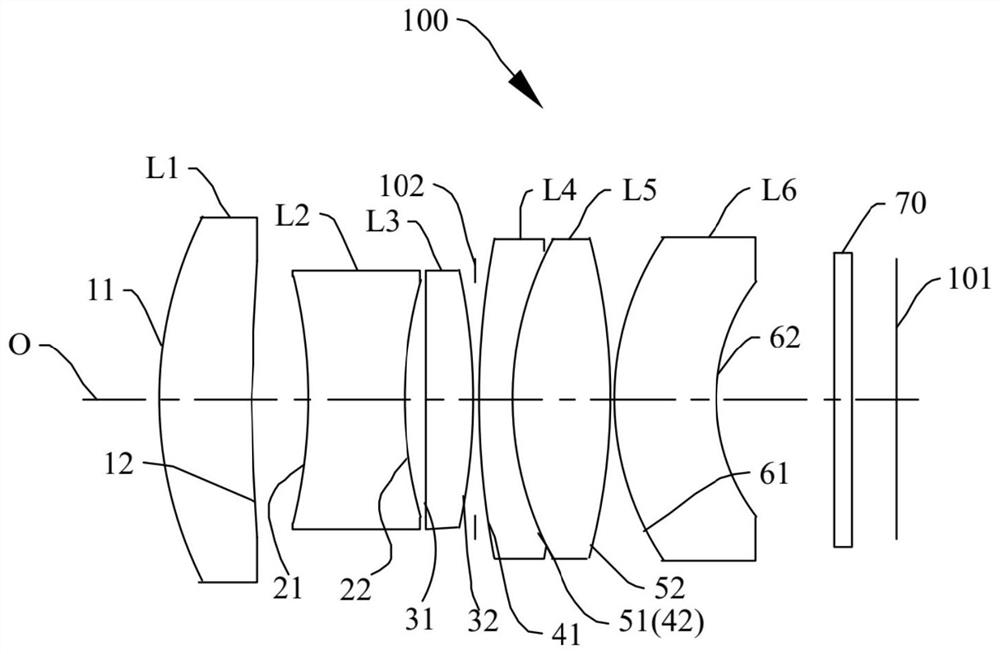

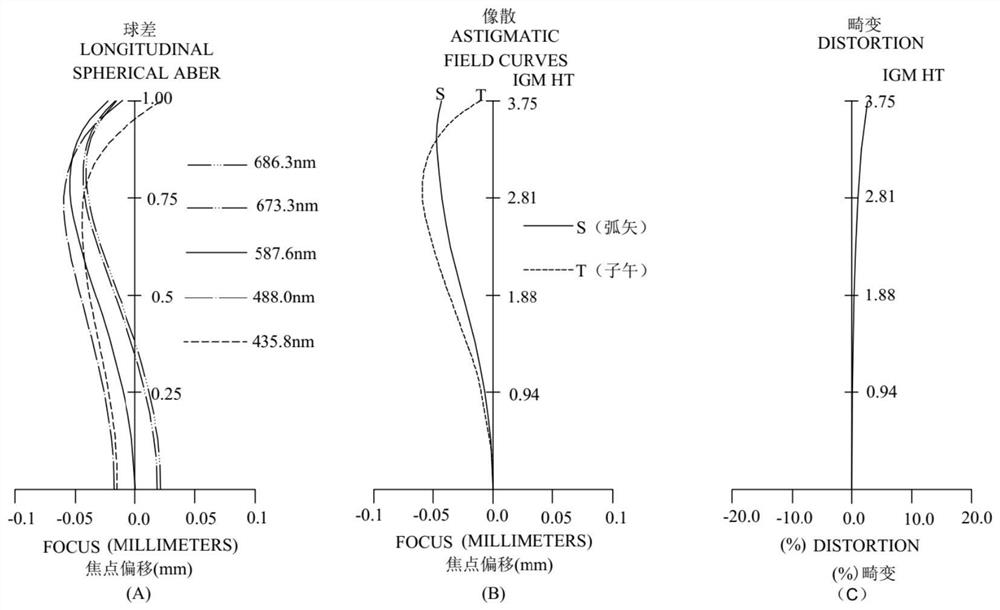

[0097] The structural diagram of the optical lens 100 disclosed in the first embodiment of the present application is as follows figure 1 As shown, the optical lens 100 includes a first lens L1, a second lens L2, a third lens L3, a diaphragm 102, a fourth lens L4, a fifth lens L5, a first lens L1, and a second lens L1 arranged in sequence from the object side to the image side along the optical axis O. Six lens L6, infrared filter 70. Among them, the first lens L1 has positive refractive power, the second lens L2 has negative refractive power, the third lens L3 has positive refractive power, the fourth lens L4 has negative refractive power, the fifth lens L5 has positive refractive power, and the sixth lens L6 may have negative inflection.

[0098] Further, the object side 11 of the first lens L1 is convex at the near optical axis O, and the image side 12 of the first lens L1 is concave at the near optical axis O; the object side 21 and image side 22 of the second lens L2 are...

no. 2 example

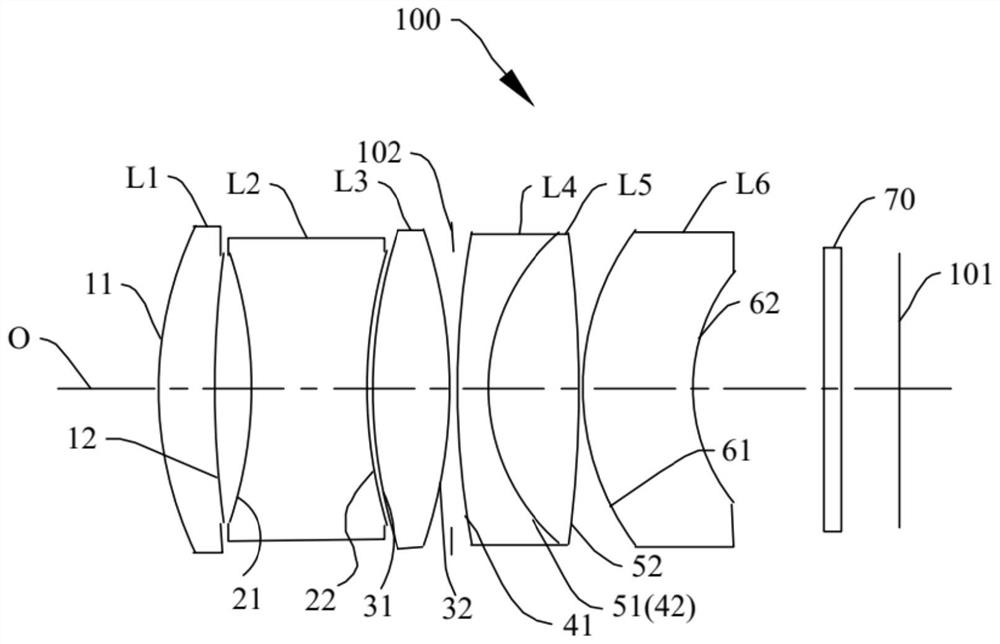

[0108] The structural diagram of the optical lens 100 disclosed in the second embodiment of the present application is as follows image 3 As shown, the optical lens 100 includes a first lens L1, a second lens L2, a third lens L3, a diaphragm 102, a fourth lens L4, a fifth lens L5, a first lens L1, and a second lens L1 arranged in sequence from the object side to the image side along the optical axis O. Six lens L6, infrared filter 70.

[0109] In the second embodiment, the refractive power, surface shape and material of the first lens L1 to the sixth lens L6 are the same as those of the first lens L1 to the sixth lens L6 in the above-mentioned first embodiment. .

[0110] Specifically, taking the effective focal length f=11.9mm of the optical lens 100, the aperture value FNO=1.6 of the optical lens 100, and the field of view FOV=34.4deg of the optical lens 100 as an example, other parameters of the optical lens 100 are given in Table 3 below out. And the definition of each...

no. 3 example

[0116] The structural diagram of the optical lens 100 disclosed in the third embodiment of the present application is as follows Figure 5 As shown, the optical lens 100 includes a first lens L1, a second lens L2, a third lens L3, a diaphragm 102, a fourth lens L4, a fifth lens L5, a first lens L1, and a second lens L1 arranged in sequence from the object side to the image side along the optical axis O. Six lens L6, infrared filter 70.

[0117] In the third embodiment, the refractive power and material of the first lens L1 to the fifth lens L5 are the same as those of the first embodiment, but in the third embodiment, the difference from the first embodiment is that the sixth lens L6 The refractive power is positive, the object side surface 31 of the third lens L3 is a concave surface, and the surface shapes of the other lenses are the same as those of the lenses in the first embodiment.

[0118] Specifically, taking the effective focal length f=10.1mm of the optical lens 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com