3.9mm high-definition glass-plastic pinhole lens and imaging method thereof

A lens and pinhole technology, applied in 3.9mm high-definition glass-plastic pinhole lens and its imaging field, can solve the problems of increased processing cost, small structure, low-cost pinhole lens, etc., achieve compact lens structure and reduce the size of lens structure , the effect of fewer structural lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

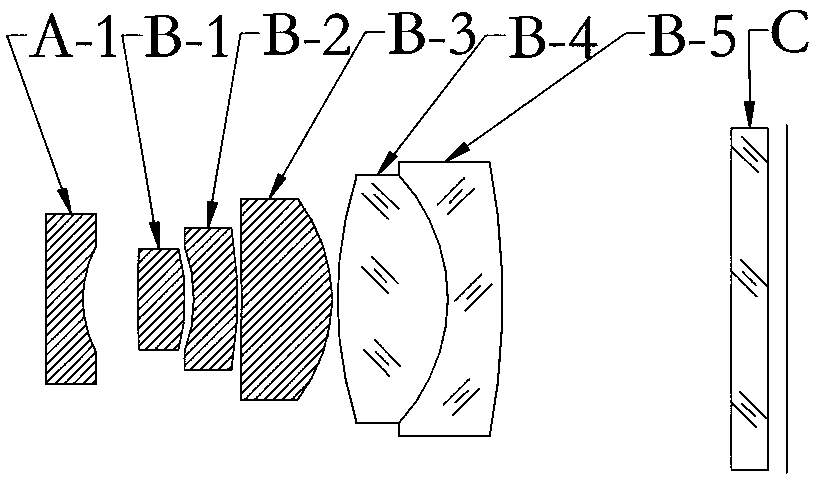

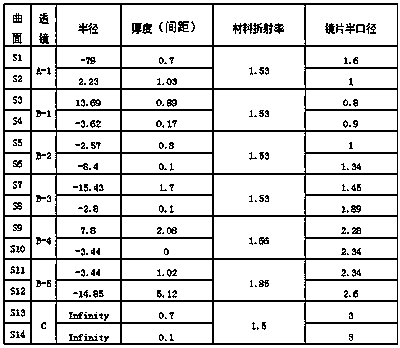

[0017] like Figures 1 to 2 As shown, a 3.9mm high-definition glass-plastic pinhole lens, the optical system of the lens is provided with a first aspherical lens A-1, a second aspherical lens B-1, a first aspherical lens A-1, a second aspherical lens B-1, a Adhesive cemented group of three aspherical lenses B-2, fourth aspherical lens B-3, biconvex lens B-4 and meniscus lens B-5; wherein the first aspherical lens A-1 constitutes a negative refractive power The front lens group, the second aspherical lens B-1, the third aspherical lens B-2, the fourth aspherical lens B-3, the biconvex lens B-4 and the meniscus lens B-5 are closely glued together to form the optical focus A rear lens with a positive degree.

[0018] In this embodiment, the focal length of the optical system is f, the first aspherical lens A-1, the second aspherical lens B-1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com