Deposit removing device and deposit removing method

A technology for attachments and exhaust ports, which is applied in the field of attachment removal devices, and can solve problems such as increased resistance of exhaust pipes, increased possibility, and large pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

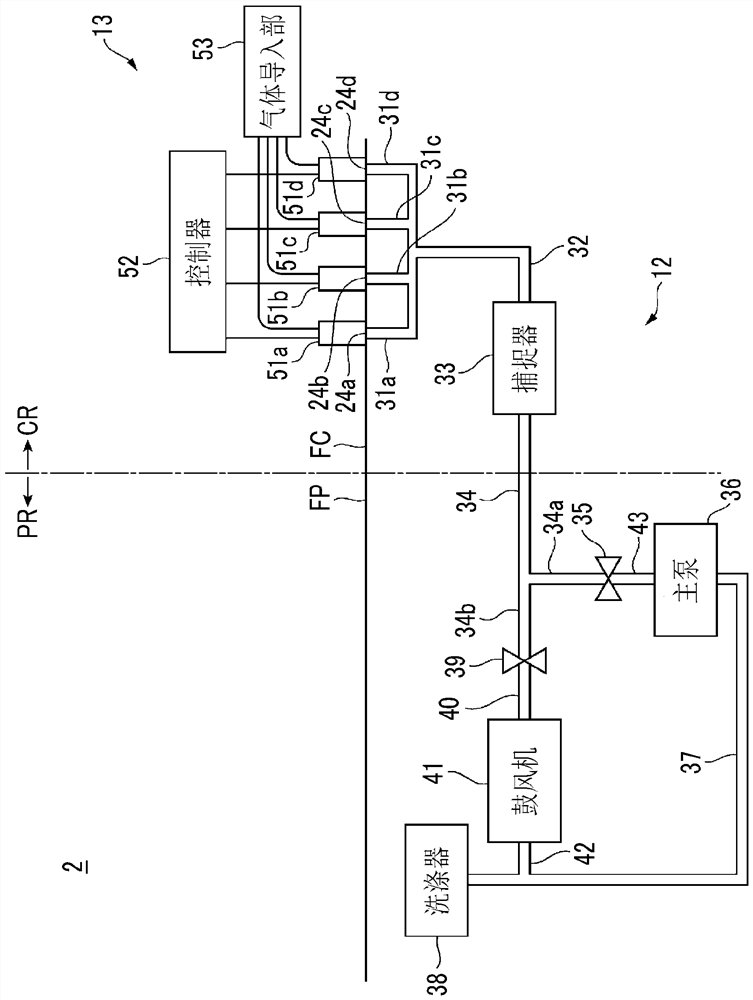

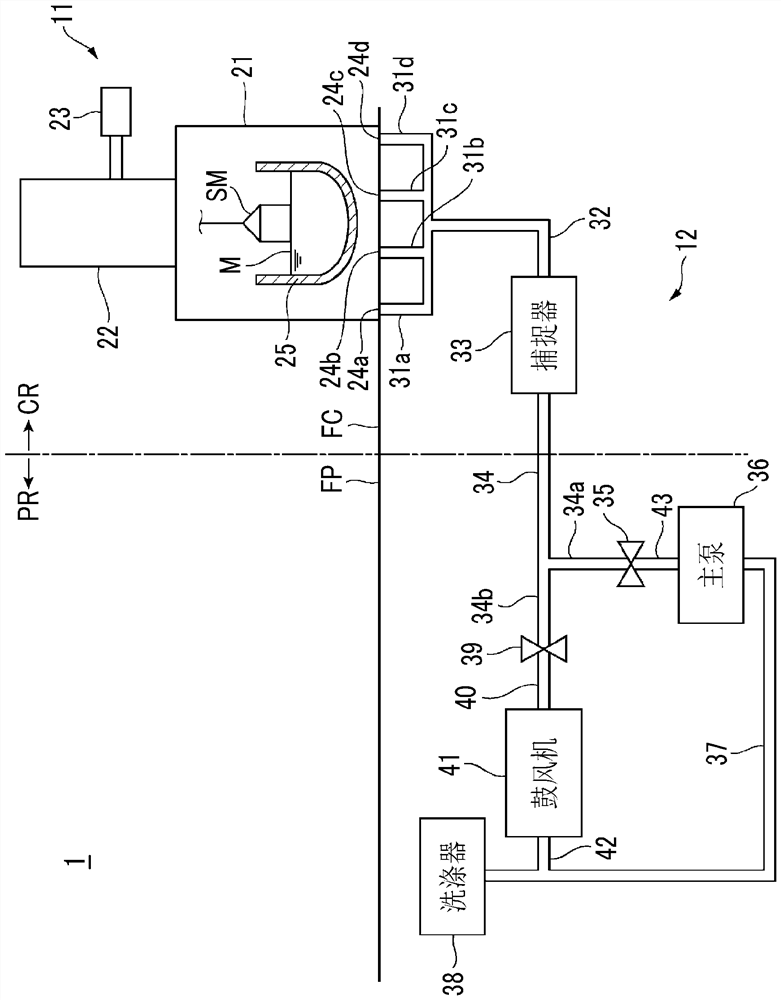

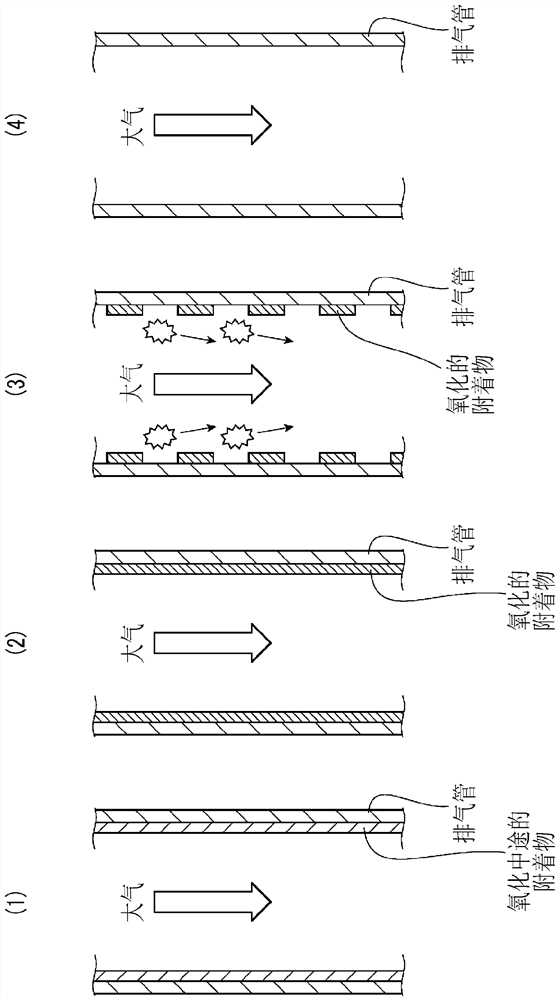

[0042] figure 1 It is a conceptual diagram showing an example of the structure of the deposit removal device 2 according to Embodiment 1 of the present invention, figure 2 It is a front view showing an example of the structure of the exhaust port opening and closing mechanism 51 a constituting the deposit removing device 2 . and, image 3 It is a conceptual diagram showing an example of the structure of the semiconductor crystal manufacturing apparatus 1 to which the deposit removal apparatus 2 is applied.

[0043] First, refer to image 3 An example of the structure of the semiconductor crystal manufacturing apparatus 1 will be described. The semiconductor crystal manufacturing apparatus 1 manufactures single crystal silicon by the CZ method. The semiconductor crystal manufacturing apparatus 1 includes a semiconductor crystal manufacturing unit 11 and a gas exhaust unit 12 .

[0044] The semiconductor crystal manufacturing unit 11 is installed on the floor FC of the cl...

Embodiment approach 2

[0092] In the first removal step of Embodiment 1 above, as Figure 7 As shown, an example in which short-term opening is performed from the first on-off valve to the fourth on-off valve after short-term opening from the first on-off valve to the fourth on-off valve is shown, but the present invention is not limited thereto. For example, short-term opening of the second on-off valve and subsequent opening of the second on-off valve may be performed multiple times after short-term opening of the first on-off valve. In addition, the order of opening and closing of the first on-off valve to the fourth on-off valve is not particularly limited.

Embodiment approach 3

[0094] In the first removal step of the above-mentioned Embodiments 1 and 2, as Figure 7 As shown, an example is shown in which only one on-off valve is opened for a short period of time, and then only the other on-off valve is opened for a short period of time after the elapse of the period T1, but it is not limited thereto. Short-term opening of a plurality of on-off valves may be simultaneously performed without passing the period T1. In this way, working time can be shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com